ASTM A105 Elbow 45, 90, 180 Degree

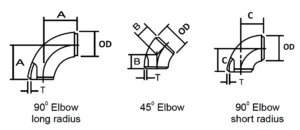

ASTM A105 Elbow is a top-tier forged carbon steel fitting designed to alter pipeline flow direction. Manufactured to meet rigorous international standards, these elbows are widely used in petrochemicals, oil and gas, power generation, and industrial piping systems. Available in 45°, 90°, and 180° configurations, these elbows provide seamless transitions while maintaining system integrity.

Key Features

- Material: Made from high-quality forged carbon steel as per ASTM A105 specifications, ensuring exceptional strength and durability.

- Versatile Design: Offered in 45°, 90°, and 180° angles for precise directional changes in pipeline systems.

- Connection Types: Available in threaded (NPT), socket weld, or butt weld ends to suit various piping requirements.

- Pressure Ratings: Supports high-pressure systems, including Class 150, 300, 600, 900, 1500, and 2500.

Specifications

- Standards: Conforms to ASTM A105 and ASME B16.9/B16.11 standards.

- Sizes: Ranges from ½” to 48″ in nominal pipe size (NPS).

- Dimensions: Precisely engineered for long-radius (LR) or short-radius (SR) configurations.

- Surface Finish: Available in black, galvanized, or custom coatings.

ASTM A105 Elbow Dimensions – Long & Short Radius Elbow Dimensions in mm

| NOMINAL PIPE SIZE | OUTSIDE DIAMETER | CENTER TO END | ||

| Inch. | OD | A | B | C |

| 1/2 | 21.3 | 38 | 16 | – |

| 3/4 | 26.7 | 38 | 19 | – |

| 1 | 33.4 | 38 | 22 | 25 |

| 1 1/4 | 42.2 | 48 | 25 | 32 |

| 1 1/2 | 48.3 | 57 | 29 | 38 |

| 2 | 60.3 | 76 | 35 | 51 |

| 2 1/2 | 73 | 95 | 44 | 64 |

| 3 | 88.9 | 114 | 51 | 76 |

| 3 1/2 | 101.6 | 133 | 57 | 89 |

| 4 | 114.3 | 152 | 64 | 102 |

| 5 | 141.3 | 190 | 79 | 127 |

| 6 | 168.3 | 229 | 95 | 152 |

| 8 | 219.1 | 305 | 127 | 203 |

| 10 | 273.1 | 381 | 159 | 254 |

| 12 | 323.9 | 457 | 190 | 305 |

| 14 | 355.6 | 533 | 222 | 356 |

| 16 | 406.4 | 610 | 254 | 406 |

| 18 | 457.2 | 686 | 286 | 457 |

| 20 | 508 | 762 | 318 | 508 |

| 22 | 559 | 838 | 343 | 559 |

| 24 | 610 | 914 | 381 | 610 |

| 26 | 660 | 991 | 406 | 660 |

| 28 | 711 | 1067 | 438 | 711 |

| 30 | 762 | 1143 | 470 | 762 |

| 32 | 813 | 1219 | 502 | 813 |

| 34 | 864 | 1295 | 533 | 864 |

| 36 | 914 | 1372 | 565 | 914 |

| 38 | 965 | 1448 | 600 | 965 |

| 40 | 1016 | 1524 | 632 | 1016 |

| 42 | 1067 | 1600 | 660 | 1067 |

| 44 | 1118 | 1676 | 695 | 1118 |

| 46 | 1168 | 1753 | 727 | 1168 |

| 48 | 1219 | 1829 | 759 | 1219 |

| All Dimensions are in mm | ||||

ASTM A105 Elbow Tolerance

| NOMINAL PIPE SIZE | ALL FITTINGS | ALL FITTINGS | ALL FITTINGS | ELBOWS AND TEES | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | REDUCERS | CAPS |

| NPS | O.D. at Bevel (1), (2) | I.D. at End | Wall Thickness (3) | Centre-to-End Dimension A,B,C,M | Centre-to-Centre O | Back-to-Face K | Alignment of Ends U | Overall Length H | Overall Length E |

| (1), (3), (4) | |||||||||

| ½ to 2½ | 0.06 | 0.03 | Not less than 87.5% of nominal thickness | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| -0.03 | |||||||||

| 3 to 3 ½ | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 4 | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 5 to 8 | 0.09 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 | |

| -0.06 | |||||||||

| 10 to 18 | 0.16 | 0.12 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| -0.12 | |||||||||

| 20 to 24 | 0.25 | 0.19 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| -0.19 | |||||||||

| 26 to 30 | 0.25 | 0.19 | 0.12 | … | … | … | 0.19 | 0.38 | |

| -0.19 | |||||||||

| 32 to 48 | 0.25 | 0.19 | 0.19 | … | … | … | 0.19 | 0.38 | |

| -0.19 |

| NOMINAL PIPE SIZE NPS | ANGULARITY TOLERANCES | ANGULARITY TOLERANCES |

| Off Angle Q | Off Plane P | |

| ½ to 4 | 0.03 | 0.06 |

| 5 to 8 | 0.06 | 0.12 |

| 10 to 12 | 0.09 | 0.19 |

| 14 to 16 | 0.09 | 0.25 |

| 18 to 24 | 0.12 | 0.38 |

| 26 to 30 | 0.19 | 0.38 |

| 32 to 42 | 0.19 | 0.5 |

| 44 to 48 | 0.18 | 0.75 |

Benefits

- High mechanical strength and corrosion resistance.

- Exceptional dimensional accuracy for leak-free connections.

- Long-lasting performance under extreme temperature and pressure conditions.

Applications

- Oil & Gas: Ideal for transporting crude oil, natural gas, and refined products.

- Petrochemical: Used in process piping for chemical plants and refineries.

- Power Generation: Suitable for steam, water, and high-temperature fluid systems.

- General Industry: Applicable in manufacturing and other industrial piping systems.

Reviews

There are no reviews yet.