Dairy Fittings

Dairy Fittings ( Stainless Steel Material)

Dairy fittings are specialized components designed for the dairy industry to ensure hygienic, safe, and efficient transfer of milk and dairy products. These fittings are critical in maintaining the integrity of dairy processing systems by preventing contamination and ensuring compliance with stringent hygiene standards. Made primarily from high-quality stainless steel (grades 304 and 316/316L), dairy fittings are engineered for durability, corrosion resistance, and ease of cleaning.

Key Features

Hygienic Design: Smooth, crevice-free surfaces to minimize bacterial growth and facilitate cleaning.

Corrosion Resistance: Made from stainless steel (AISI 304, 316, or 316L) to withstand harsh cleaning agents and high-humidity environments.

Versatility: Available in various configurations, including elbows, tees, reducers, unions, and clamps, to suit diverse system requirements.

Compliance: Meets international standards such as DIN 11851, DIN 11853, DIN 11864, SMS, IDF, and ISO for food safety and hygiene.

Ease of Maintenance: Designed for quick assembly and disassembly, reducing downtime during cleaning and maintenance.

Material Specifications

Material Grades

AISI 304 (EN 1.4301)

AISI 316/316L (EN 1.4401/1.4404)

Surface Roughness

Hygienic applications: Ra ≤ 0.8 µm.

Aseptic applications: Ra ≤ 0.4 µm.

Standards Compliance

- DIN 11851, DIN 11853, DIN 11864, DIN 32676 (Tri-Clamp), SMS, IDF, ISO, and AS 1528.3

Types of Dairy Fittings

Unions

SMS Union: Compact, hygienic screw coupling with improved seals for food and brewery applications.

DIN 11851: Standard milk fittings for dairy systems with moderate hygiene requirements.

DIN 11864: Aseptic fittings with minimal dead spaces for pharmaceutical and high-hygiene dairy applications.

Tri-Clover/Tri-Clamp (DIN 32676): Clamp-based fittings for quick assembly/disassembly, ideal for food and pharmaceutical industries.

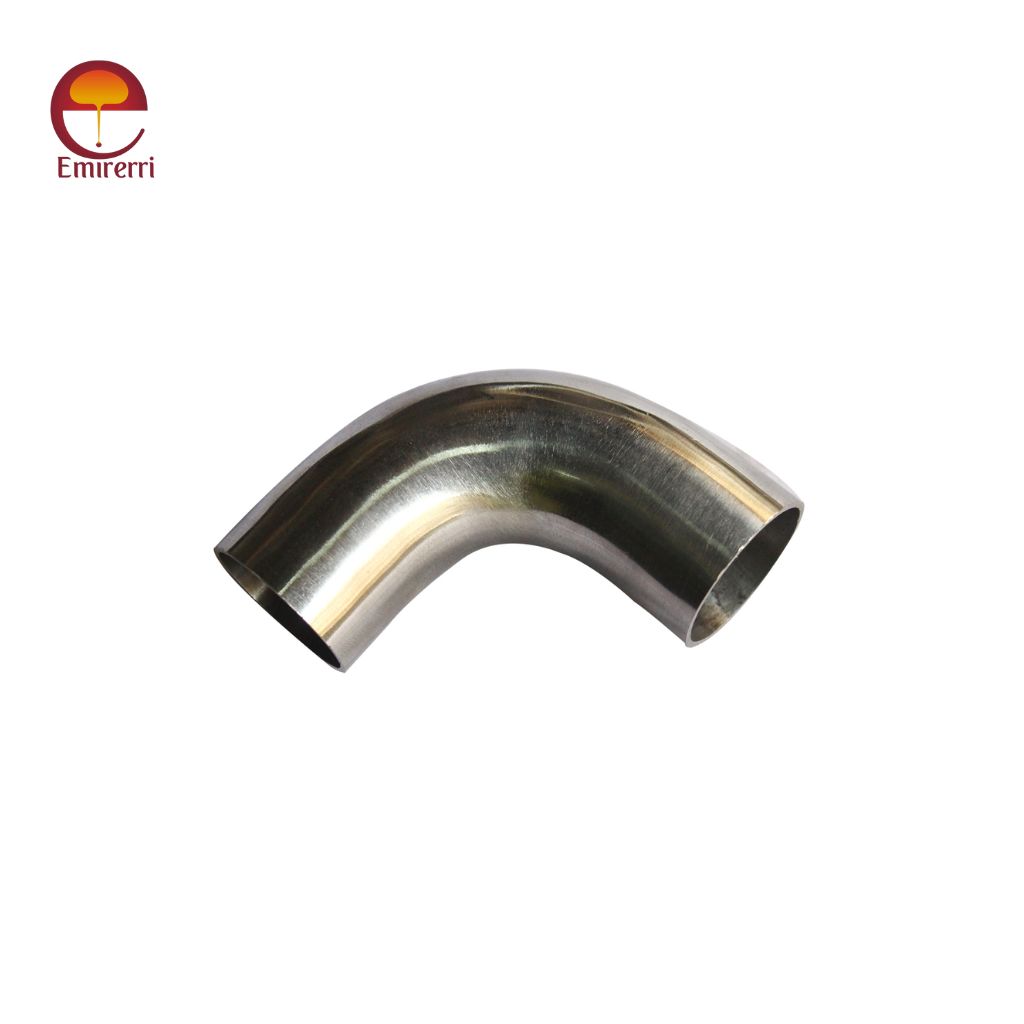

Bends/Elbows

Angles: 45°, 90°, or custom.

Bending Radius: R=1D, 2D, 3D, 5D, 6D, 8D, 10D, or custom.

Tees and Reducers

Connect pipes of varying diameters or redirect flow.

Available in welded, threaded, or clamped configurations.

Clamps and Ferrules

Securely seal two ferrules with hygienic clamps.

Sizes: 1/4” to 8” (O.D.) or DN 10 to DN 150.

Valves

Types: Butterfly valves, ball valves, seat valves, mixproof valves.

Control: Manual or pneumatic with valve control units (e.g., IO-link, digital, or bus communication).

Features: Seat lift indication, maintenance alerts for plug seals.

Dimensional Specifications

Pipe Sizes

Outer Diameter (O.D.): 1/4” to 8” (6.35 mm to 203.2 mm).

Nominal Bore (N.B.): 1/4” to 8” (DN 10 to DN 150).

Wall Thickness

- 1 mm to 5 mm, depending on fitting type and application.

Connection Types

Welded: Permanent joints for fixed installations.

Threaded: For easy disconnection (e.g., SMS, BSP, NPT).

Clamped: Tri-Clamp or other sanitary clamp systems for quick assembly.

Pressure Ratings

- Designed to handle pressures up to 10 bar (145 psi), with high-pressure options available.

Applications

Dairy Processing: Milk, cream, and yogurt transfer systems.

Food and Beverage: Breweries, soft drink production, and food processing.

Pharmaceuticals: High-hygiene systems for drug manufacturing.

Chemical Industry: Handling corrosive liquids in controlled environments.