ASTM A182 F1

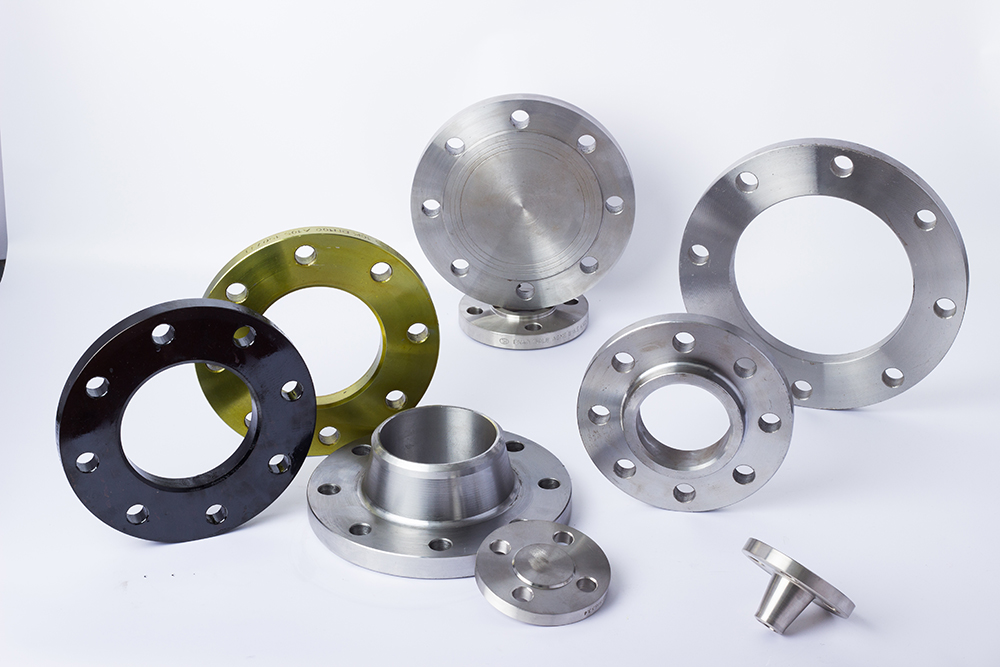

ASTM A182 F1 Alloy Steel Forged Fittings & Flanges

ASTM A182 F1 is a low-alloy steel grade primarily containing chromium and molybdenum (0.5% Mo). It is widely used for forged flanges, fittings, valves, and high-pressure piping components. The grade offers moderate strength, good ductility, and enhanced resistance to corrosion and high-temperature environments.

F1 is preferred in refinery, power generation, petrochemical, and boiler applications, where stable performance under higher temperatures and pressures is essential. Its excellent weldability and ease of fabrication make it a versatile material for various industrial systems.

Key Features

Excellent weldability and machinability

Good high-temperature strength

Enhanced resistance to oxidation and scaling

Suitable for moderate pressure and temperature services

Good toughness and ductility

Reliable performance in steam, oil, and gas environments

Specification

| Property | Details |

|---|---|

| Grade | ASTM A182 F1 |

| UNS | K12822 |

| Material | 0.5% Cr–0.5% Mo Alloy Steel |

| Standard | ASTM A182 / ASME SA182 |

| Classes | 150, 300, 600, 900, 1500, 2500 |

| Product Forms | Flanges, Fittings, Rings, Bars, Valves |

| Manufacturing | Forged / Rolled / Heat Treated |

| Condition | Annealed / Normalized & Tempered |

| Size Range | ½” to 48” (varies by product) |

Equivalent Grades

| Standard | Grade |

|---|---|

| ASME | SA182 F1 |

| UNS | K12822 |

| WNR | 1.5415 |

| EN | 16Mo5 (Similar) |

| BS | 3603-622-310 (Approx.) |

Available Sizes

Flanges

½” to 48”

Class 150–2500

Forged Fittings

½” to 4”

3000#, 6000#, 9000#

Bars & Shafts

20mm to 500mm diameter

Custom Forgings

Blocks, rings, discs, special-machined components

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.05 – 0.15 |

| Manganese (Mn) | 0.30 – 0.60 |

| Silicon (Si) | 0.10 – 0.50 |

| Chromium (Cr) | 0.30 – 0.60 |

| Molybdenum (Mo) | 0.45 – 0.65 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 380 MPa (Min) |

| Yield Strength | 205 MPa (Min) |

| Elongation | 20% (Min) |

| Hardness | ≤ 170 HB |

| Impact Strength | Good at room and moderate temperatures |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.80 g/cm³ |

| Melting Point | 1420–1460°C |

| Thermal Conductivity | ~46 W/m·K |

| Modulus of Elasticity | 200 GPa |

| Specific Heat | 460 J/kg·K |

Types

1. Forged Flanges

Weld Neck Flange

Blind Flange

Slip-On Flange

Socket Weld Flange

Threaded Flange

Lap Joint Flange

RTJ Flange

Orifice Flange

2. Forged Fittings

45° / 90° Elbow

Tee (Equal / Reducing)

Cross

Coupling

Union

Cap & Plug

Swage Nipple

3. Custom Forgings

Rings

Bars

Shafts

Discs

Blocks

Corrosion Resistance

ASTM A182 F1 offers:

Moderate resistance to atmospheric corrosion

Good oxidation resistance in steam environments

Suitable for mildly corrosive oil & gas media

Performs well in refinery and petrochemical service

Not recommended for high-chloride environments or strong acids.

Heat Resistance

Stable performance up to 450–500°C

Good resistance to scaling and oxidation

Adequate strength for moderate high-temperature applications

Suitable for heat exchanger and boiler components

Heat Treatment

| Process | Temperature |

|---|---|

| Annealing | 900–950°C |

| Normalizing | 900–940°C |

| Tempering | 540–700°C |

| Hardening | Not applicable |

| PWHT after welding | 650–750°C |

Welding

F1 is easily weldable using:

GTAW / TIG

GMAW / MIG

SMAW

SAW

Welding Requirements

Preheat: 100–200°C

Interpass temperature control needed

PWHT recommended to avoid hardness buildup

Use low-hydrogen welding consumables

Fabrication

Highly formable and forgeable between 900–1200°C

Good machinability after annealing

Suitable for custom-shaped forgings

Maintains structural stability during heavy processing

Applications

Oil & Gas refineries

Power plants

Petrochemical industry

Heat exchanger systems

Boiler tubes and headers

Steam pipelines

Pressure vessels

Processing equipment for moderate temperatures