ASTM A182 F5

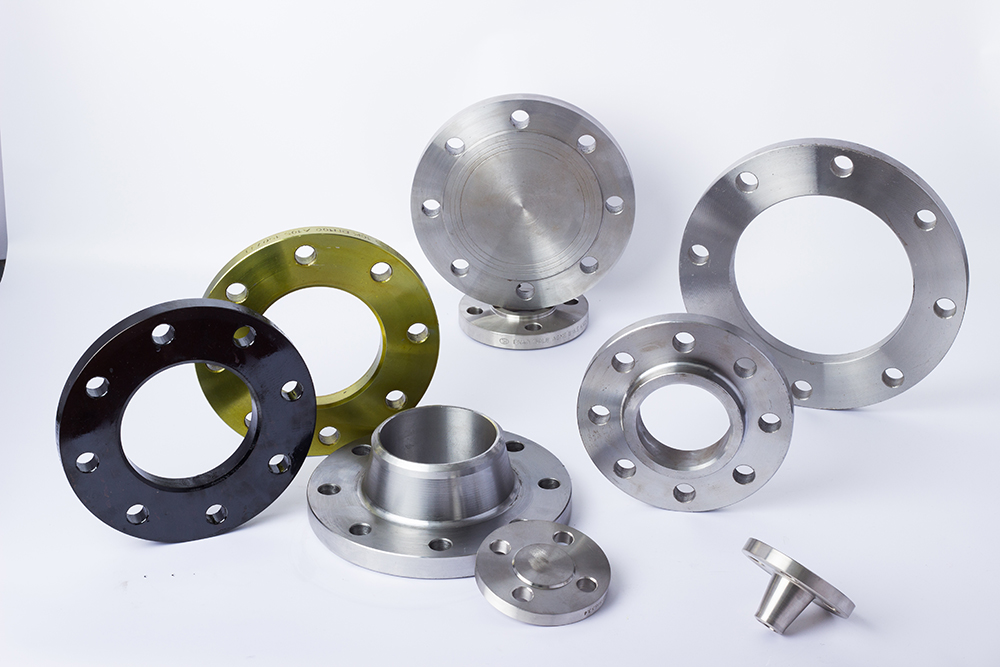

ASTM A182 F5 Alloy Steel Forged Fittings / Flanges

ASTM A182 F5 is a standard specification for forged or rolled alloy steel pipe flanges, fittings, valves, and parts intended for high-temperature service. The F5 grade is a chromium-molybdenum alloy steel (5Cr-0.5Mo) that provides excellent strength, toughness, and oxidation resistance at elevated temperatures.

Emirerri Steel manufactures and supplies ASTM A182 F5 Forged Fittings and Flanges engineered to deliver reliable performance under extreme pressure and temperature conditions, widely used in petrochemical plants, refineries, power generation units, and boiler systems.

Key Features

Superior resistance to oxidation and scaling at high temperatures

High tensile and creep strength

Excellent toughness and durability

Good weldability and machinability

Precise dimensions and tight tolerances

Long service life in demanding conditions

Specification

| Specification | Details |

|---|---|

| Standard | ASTM A182 / ASME SA182 |

| Grade | F5 |

| Material | Alloy Steel (5Cr-0.5Mo) |

| Manufacturing Type | Forged / Rolled / Heat Treated |

| Size Range | ½” NB to 48” NB |

| Pressure Rating | Class 150 to 2500 |

| Dimensions | ASME B16.5, ASME B16.11, MSS SP-79 / SP-95 |

| Connection Type | Socket Weld / Threaded / Flanged |

| Form | Elbow, Tee, Cross, Union, Coupling, Plug, Cap, Flange |

Equivalent Grades

| Standard | Equivalent Grade |

|---|---|

| ASTM | A182 F5 |

| ASME | SA182 F5 |

| UNS | K41545 |

| EN | 1.7362 |

| DIN | X12CrMo9-1 |

| BS | 1503-241A |

Available Sizes

Forged Fittings: ½” NB to 4” NB

Flanges: ½” NB to 48” NB

Pressure Class: 150#, 300#, 600#, 900#, 1500#, 2500#

Thickness: SCH 10S to SCH XXS

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.15 max |

| Manganese (Mn) | 0.30 – 0.60 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

| Silicon (Si) | 0.50 – 1.00 |

| Chromium (Cr) | 4.00 – 6.00 |

| Molybdenum (Mo) | 0.45 – 0.65 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 415 MPa (min) |

| Yield Strength | 205 MPa (min) |

| Elongation | 20% (min) |

| Hardness (Brinell) | ≤ 197 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1420–1540°C |

| Thermal Conductivity | 24 W/m·K at 100°C |

| Electrical Resistivity | 0.16 µΩ·m at 20°C |

| Modulus of Elasticity | 205 GPa |

Types of ASTM A182 F5 Products

Forged Fittings: Elbow, Tee, Cross, Coupling, Plug, Union, Cap

Flanges: Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Lap Joint

Outlet Fittings: Weldolet, Sockolet, Threadolet

Custom Components: Valve Parts, Discs, Rings, Connectors

Corrosion Resistance

ASTM A182 F5 Alloy Steel provides moderate resistance to oxidation, carburization, and sulfidation in hot environments. The presence of 5% chromium enhances oxidation resistance, while molybdenum improves pitting and high-temperature corrosion performance. It is not recommended for highly acidic environments without protective coatings.

Heat Resistance

F5 grade is designed for high-temperature service up to 600°C (1112°F). It maintains its mechanical strength, creep resistance, and stability even under fluctuating temperature cycles, making it suitable for steam and power applications.

Heat Treatment

Normalizing: 950–1000°C followed by air cooling

Tempering: 700–750°C to achieve optimal mechanical properties

Annealing: 870–920°C to relieve stress and refine grain structure

Proper heat treatment enhances toughness, ductility, and corrosion resistance.

Welding

ASTM A182 F5 can be welded using TIG, MIG, or SMAW processes. Preheating to 200–300°C and post-weld heat treatment (PWHT) are essential to avoid cracking and to maintain mechanical stability. Use filler metals compatible with 5Cr-0.5Mo composition for best results.

Fabrication

The alloy steel F5 is readily forgeable and machinable using conventional processes. Controlled forging temperature between 900°C–1200°C ensures uniform deformation and excellent surface finish. Post-fabrication heat treatment is recommended for improved dimensional stability.

Applications

Power Generation Boilers & Superheaters

Heat Exchangers and Steam Lines

Oil & Gas Refining Equipment

Petrochemical Processing Plants

Pressure Vessels and Reactors

High-Temperature Piping Systems