ASTM A182 F11

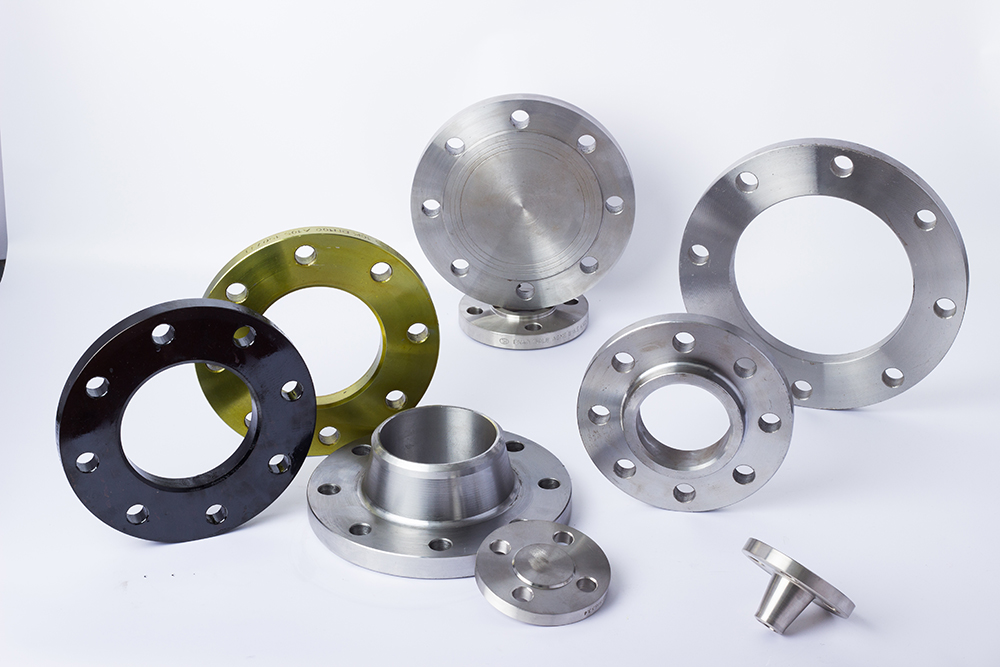

ASTM A182 F11 Alloy Steel Forged Fittings / Flanges

ASTM A182 F11 is a specification covering forged or rolled alloy steel pipe flanges, fittings, valves, and parts designed for high-temperature and high-pressure applications. The F11 grade (1¼Cr-½Mo) is a chromium-molybdenum alloy that offers an excellent balance of strength, toughness, and resistance to oxidation and creep at elevated temperatures.

Emirerri Steel manufactures and supplies premium-quality ASTM A182 F11 Forged Fittings and Flanges, ensuring exceptional dimensional accuracy, durability, and performance in industries such as power generation, refineries, chemical processing, and heat exchangers.

Key Features

Superior strength and creep resistance at high temperatures

Excellent oxidation and scaling resistance

Enhanced weldability and machinability

High resistance to pressure and thermal stress

Long-lasting performance with low maintenance

Manufactured to meet international standards (ASME / ASTM / DIN / EN)

Specification

| Specification | Details |

|---|---|

| Standard | ASTM A182 / ASME SA182 |

| Grade | F11 |

| Material | Alloy Steel (1¼Cr-½Mo) |

| Manufacturing Type | Forged / Rolled / Heat Treated |

| Size Range | ½” NB to 48” NB |

| Pressure Rating | Class 150 to 2500 |

| Connection Type | Socket Weld / Threaded / Flanged |

| Dimensions | ASME B16.5, ASME B16.11, MSS SP-79 / SP-95 |

| Form | Elbow, Tee, Cross, Union, Coupling, Plug, Cap, Flange |

Equivalent Grades

| Standard | Equivalent Grade |

|---|---|

| ASTM | A182 F11 |

| ASME | SA182 F11 |

| UNS | K11572 |

| EN | 1.7335 |

| DIN | 13CrMo4-5 |

| BS | 1503-241A |

Available Sizes

Forged Fittings: ½” NB to 4” NB

Flanges: ½” NB to 48” NB

Pressure Class: 150#, 300#, 600#, 900#, 1500#, 2500#

Thickness: SCH 10S to SCH XXS

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.05 – 0.15 |

| Manganese (Mn) | 0.30 – 0.60 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

| Silicon (Si) | 0.50 – 1.00 |

| Chromium (Cr) | 1.00 – 1.50 |

| Molybdenum (Mo) | 0.44 – 0.65 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 415 MPa (min) |

| Yield Strength | 205 MPa (min) |

| Elongation | 20% (min) |

| Hardness (Brinell) | ≤ 197 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1425–1540°C |

| Thermal Conductivity | 25 W/m·K at 100°C |

| Electrical Resistivity | 0.16 µΩ·m at 20°C |

| Modulus of Elasticity | 205 GPa |

Types of ASTM A182 F11 Products

Forged Fittings: Elbow, Tee, Cross, Union, Coupling, Plug, Cap

Flanges: Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Lap Joint

Outlet Fittings: Weldolet, Sockolet, Threadolet

Custom Forged Components: Valve Parts, Discs, Rings, Connectors

Corrosion Resistance

ASTM A182 F11 Alloy Steel provides moderate resistance to oxidation, carburization, and sulfidation in high-temperature environments. The chromium and molybdenum content offers protection against scaling and corrosion in steam and gas service, though additional coatings are recommended for use in highly corrosive or acidic environments.

Heat Resistance

The chromium-molybdenum composition offers excellent heat resistance up to 600°C (1112°F). F11 alloy steel retains strength and creep resistance under continuous thermal exposure, making it ideal for components in boilers, turbines, and steam piping.

Heat Treatment

Normalizing: 950–1000°C followed by air cooling

Tempering: 700–750°C to improve ductility and mechanical properties

Annealing: 870–920°C to relieve internal stresses and refine grain structure

Welding

ASTM A182 F11 can be welded using TIG, MIG, or SMAW processes. Preheating at 200–300°C and post-weld heat treatment (PWHT) are essential to avoid cracking and preserve strength. Use matching filler materials such as ER80S-B2 or E8018-B2 for best results.

Fabrication

F11 alloy steel is easily forgeable and machinable using conventional techniques. It requires controlled temperature management during hot working between 900°C–1200°C. Post-fabrication heat treatment enhances structural uniformity and stress relief.

Applications

Power Generation Boilers & Steam Lines

Heat Exchangers and Pressure Vessels

Oil & Gas Refining Units

Petrochemical and Fertilizer Plants

Turbine Components and Piping Systems

Superheaters and Reheaters