ASTM A105 Carbon Steel Socket Weld Concentric and Eccentric Reducers

The American Society for Testing and Materials (ASTM) developed the ASTM A105 specification for forged carbon steel piping components. These components are designed to withstand high-temperature and high-pressure conditions, making them ideal for use in industries such as oil and gas, petrochemicals, power generation, and more. Among the various fittings made from ASTM A105 material, socket weld concentric and eccentric reducers play a critical role in piping systems, ensuring smooth transitions between pipes of different sizes while maintaining system integrity.

Understanding Socket Weld Reducers

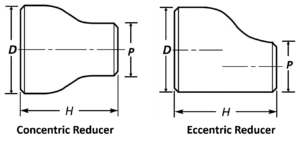

Socket weld reducers are essential pipe fittings used to connect pipes of varying diameters. They are specifically designed for high-pressure applications, offering a leak-proof joint when properly welded. There are two primary types of socket weld reducers:

- Concentric Reducers:

-

- These reducers have a symmetrical design, where the centerline of the larger and smaller pipe diameters aligns.

- They are commonly used in vertical piping systems or applications where maintaining a consistent flow path is crucial.

- Eccentric Reducers:

- These reducers have an asymmetrical design, where the centerline of the larger and smaller pipe diameters does not align.

- They are often used in horizontal piping systems to prevent air pockets and ensure proper drainage.

Both types of reducers are available in various sizes, pressure ratings, and specifications to meet the diverse requirements of industrial applications.

Concentric and Eccentric Reducer Dimensions

| NOMINAL PIPE SIZE | OUTSIDE DIAMETER | END TO END | |

| Inch | D | P | H |

| 3/4 x 1/2 | 26.7 | 21.3 | 38 |

| 3/4 x 3/8 | 26.7 | 17.1 | 38 |

| 1 x 3/4 | 33.4 | 26.7 | 51 |

| 1 x 1/2 | 33.4 | 21.3 | 51 |

| 1 1/4 x 1 | 42.2 | 33.4 | 51 |

| 1 1/4 x 3/4 | 42.2 | 26.7 | 51 |

| 1 1/4 x 1/2 | 42.2 | 21.3 | 51 |

| 1 1/2 x 1 1/2 | 48.3 | 42.2 | 64 |

| 1 1/2 x 1 | 48.3 | 33.4 | 64 |

| 1 1/2 x 3/4 | 48.3 | 26.7 | 64 |

| 1 1/2 x 1/2 | 48.3 | 21.3 | 64 |

| 2 x 1 1/2 | 60.3 | 48.2 | 76 |

| 2 x 1 1/4 | 60.3 | 42.2 | 76 |

| 2 x 1 | 60.3 | 33.4 | 76 |

| 2 x 3/4 | 60.3 | 26.7 | 76 |

| 2 1/2 x 2 | 73 | 60.3 | 89 |

| 2 1/2 x 1 1/2 | 73 | 48.3 | 89 |

| 2 1/2 x 1 1/4 | 73 | 42.2 | 89 |

| 2 1/2 x 1 | 73 | 33.4 | 89 |

| 3 x 2 1/2 | 88.9 | 73 | 89 |

| 3 x 2 | 88.9 | 60.3 | 89 |

| 3 x 1 1/2 | 88.9 | 48.3 | 89 |

| 3 x 1 1/4 | 88.9 | 42.2 | 89 |

| 3 1/2 x 3 | 101.6 | 88.9 | 102 |

| 3 1/2 x 21/2 | 101.6 | 73 | 102 |

| 3 1/2 x 2 | 101.6 | 60.3 | 102 |

| 3 1/2 x 1 1/2 | 101.6 | 48.3 | 102 |

| 3 1/2 x 1 1/4 | 101.6 | 42.2 | 102 |

| 4 x 3 1/2 | 114.3 | 101.6 | 102 |

| 4 x 3 | 114.3 | 88.9 | 102 |

| 4 x 2 1/2 | 114.3 | 73 | 102 |

| 4 x 2 | 114.3 | 60.3 | 102 |

| 4 x 1 1/2 | 114.3 | 48.3 | 102 |

| 5 x 4 | 141.3 | 114.3 | 127 |

| 5 x 3 1/2 | 141.3 | 101.6 | 127 |

| 5 x 3 | 141.3 | 88.9 | 127 |

| 5 x 2 1/2 | 141.3 | 73 | 127 |

| 5 x 2 | 141.3 | 60.3 | 127 |

| 6 x 5 | 168.3 | 141.3 | 140 |

| 6 x 4 | 168.3 | 114.3 | 140 |

| 6 x 3 1/2 | 168.3 | 101.6 | 140 |

| 6 x 3 | 168.3 | 88.9 | 140 |

| 6 x 2 1/2 | 168.3 | 73 | 140 |

| 8 x 6 | 219.1 | 168.3 | 152 |

| 8 x 5 | 219.1 | 141.3 | 152 |

| 8 x 4 | 219.1 | 114.3 | 152 |

| 8 x 3 1/2 | 219.1 | 101.6 | 152 |

| 10 x 8 | 273.1 | 219.1 | 178 |

| 10 x 6 | 273.1 | 168.1 | 178 |

| 10 x 5 | 273.1 | 141.3 | 178 |

| 10 x 4 | 273.1 | 114.3 | 178 |

| 12 x 10 | 323.9 | 273.1 | 203 |

| 12 x 8 | 323.9 | 219.1 | 203 |

| 12 x 6 | 323.9 | 168.3 | 203 |

| 12 x 5 | 323.9 | 141.3 | 203 |

| 14 x 12 | 355.6 | 323.9 | 330 |

| 14 x 10 | 355.6 | 273.1 | 330 |

| 14 x 8 | 355.6 | 219.1 | 330 |

| 14 x 6 | 355.6 | 168.3 | 330 |

| 16 x 14 | 406.4 | 355.6 | 356 |

| 16 x 12 | 406.4 | 323.9 | 356 |

| 16 x 10 | 406.4 | 273.1 | 356 |

| 16 x 8 | 406.4 | 219.1 | 356 |

| 16 x 6 | 406.4 | 168.3 | 356 |

| 18 x 16 | 457 | 406.4 | 381 |

| 18 x 14 | 457 | 355.6 | 381 |

| 18 x 12 | 457 | 323.9 | 381 |

| 18 x 10 | 457 | 273.1 | 381 |

| 18 x 8 | 457 | 219.1 | 381 |

| 20 x 18 | 508 | 457 | 508 |

| 20 x 16 | 508 | 406.4 | 508 |

| 20 x 14 | 508 | 355.6 | 508 |

| 20 x 12 | 508 | 323.9 | 508 |

| 20 x 10 | 508 | 273.1 | 508 |

| 20 x 8 | 508 | 219.1 | 508 |

| 22 x 20 | 559 | 508 | 508 |

| 22 x 18 | 559 | 457 | 508 |

| 22 x 16 | 559 | 406.4 | 508 |

| 22 x 14 | 559 | 355.6 | 508 |

| 22 x 12 | 559 | 323.9 | 508 |

| 24 x 10 | 559 | 273.1 | 508 |

| 24 x 22 | 610 | 559 | 508 |

| 24 x 20 | 610 | 508 | 508 |

| 24 x 18 | 610 | 457 | 508 |

| 24 x 16 | 610 | 406.4 | 508 |

| 24 x 14 | 610 | 355.6 | 508 |

| 24 x 12 | 610 | 323.9 | 508 |

| 24 x 10 | 610 | 273.1 | 508 |

| All Dimensions are in mm | |||

Key Features of ASTM A105 Socket Weld Reducers

- Material Composition:

-

-

- ASTM A105 material is forged carbon steel, known for its high tensile strength, durability, and excellent resistance to wear and tear.

- The material’s chemical composition includes carbon, manganese, phosphorus, sulfur, and silicon, ensuring optimal performance in demanding conditions.

-

- Strength and Durability:

-

-

- These reducers exhibit exceptional mechanical properties, including high yield and tensile strength.

- They can withstand extreme pressure and temperature fluctuations without compromising structural integrity.

-

- Leak-Proof Connections:

-

-

- The socket weld design ensures a secure and leak-proof connection, making them ideal for critical applications.

- Proper welding techniques enhance the reliability of these fittings, minimizing the risk of failures.

-

- Corrosion Resistance:

-

-

- Although ASTM A105 is not inherently corrosion-resistant, it can be coated or treated to enhance its performance in corrosive environments.

-

- Versatility:

-

- Available in a wide range of sizes and configurations, these reducers are suitable for various industrial applications.

Applications of ASTM A105 Socket Weld Reducers

Socket weld concentric and eccentric reducers manufactured from ASTM A105 material are extensively used in:

- Oil and Gas Industry:

-

-

- Used in pipelines to convey crude oil, natural gas, and refined products.

- Ensures smooth flow transitions and minimizes pressure drop.

-

- Petrochemical Plants:

-

-

- Essential for chemical processing systems where precise flow control is critical.

-

- Power Generation:

-

-

- Used in steam and water piping systems within power plants to handle high pressures and temperatures.

-

- Water Treatment Plants:

-

-

- Suitable for piping systems that require robust fittings to manage varying water flow rates.

-

- General Industrial Applications:

-

- Used in manufacturing facilities, HVAC systems, and other industrial setups for reliable performance.

Manufacturing Standards and Specifications

ASTM A105 socket weld reducers are manufactured in compliance with stringent industry standards to ensure quality and performance. Key standards include:

- ASTM A105 specifies forged carbon steel piping components.

- ASME B16.11 is the standard for forged fittings, including socket welds and threaded fittings.

- ANSI/ASME B1.20.1: Standards for pipe threads where applicable.

These standards govern dimensions, tolerances, pressure ratings, and other critical parameters, ensuring compatibility and reliability.

Advantages of Using ASTM A105 Socket Weld Reducers

- Enhanced Performance:

-

-

- The high-strength material ensures reliable performance under extreme conditions.

-

- Cost-Effective:

-

-

- Carbon steel fittings are more economical than other materials like stainless steel or alloy steel, without compromising on quality.

-

- Ease of Installation:

-

-

- The socket weld design makes installation easier, lowering labor and time requirements.

-

- Customizable Options:

-

- Available in a variety of sizes and combinations to suit unique project needs.

Quality Assurance and Testing

Manufacturers of ASTM A105 socket weld reducers implement rigorous quality control measures to ensure product reliability. Common testing procedures include:

- Chemical Analysis:

-

-

- Verifies the material’s composition to ensure compliance with ASTM A105 standards.

-

- Mechanical Testing:

-

-

- Includes tensile strength, yield strength, and elongation tests to evaluate mechanical properties.

-

- Hydrostatic Testing:

-

-

- Ensures the fittings can withstand specified pressure levels without leaking or failing.

-

- Non-Destructive Testing (NDT):

-

-

- Methods such as ultrasonic testing, magnetic particle inspection, and radiography are used to detect surface and subsurface defects.

-

- Dimensional Inspection:

-

- Confirm that the fittings’ dimensions and tolerances meet ASME B16.11 specifications.

Maintenance and Care

To maximize the lifespan and performance of ASTM A105 socket weld reducers:

- Regular Inspection:

-

-

- Inspect for wear, corrosion, or damage on a regular basis.

-

- Proper Installation:

-

-

- Follow industry best practices and welding procedures to ensure secure connections.

-

- Protective Coatings:

-

-

- Apply suitable coatings to improve corrosion resistance in severe situations.

-

- Timely Replacement:

-

- Replace worn-out or damaged fittings promptly to prevent system failures.

Conclusion

ASTM A105 carbon steel socket weld concentric and eccentric reducers are indispensable components in modern piping systems. Their superior strength, durability, and cost-effectiveness make them a preferred choice for industries handling high-pressure and high-temperature applications. By adhering to stringent manufacturing standards and proper installation practices, these reducers ensure long-term performance and reliability. Whether used in oil and gas pipelines, petrochemical plants, or power generation facilities, ASTM A105 socket weld reducers are a testament to engineering excellence and innovation.

Reviews

There are no reviews yet.