ASTM A234 WPB Stub End

ASTM A234 WPB Stub End is an essential component in piping systems, renowned for its reliability and versatility. Fabricated to meet the ASTM A234 WPB specification, this stub end is designed to connect pipes in high-temperature and high-pressure applications. Stub ends are particularly valuable in systems that require frequent dismantling or where ease of maintenance is a priority. Their ability to reduce stress concentration in piping systems makes them a preferred choice across diverse industries.

The “WPB” in ASTM A234 WPB stands for:

- Wrought

- Piping

- B refers to grade B, indicating the composition of carbon steel used.

A stub end is a short pipe with a flared and square-cut end. The flared end is designed to mate with a backing flange, enabling quick disassembly of pipelines. This combination offers a more cost-effective alternative to traditional flanged joints in certain applications. Stub ends are typically categorized into three types:

- ASTM A234 WPB Type A Stub End: Designed to fit standard lap joint flanges.

- ASTM A234 WPB Type B Stub End: Works with slip-on flanges.

- ASTM A234 WPB Type C Stub End: Universal design that fits lap joint and slip-on flanges.

Key Features

- High Strength: The carbon steel material offers superior tensile strength and durability.

- Temperature Resistance: Suitable for high-temperature applications.

- Corrosion Resistance: Enhanced protection against general corrosion when properly coated or galvanized.

- Versatile Design: Available in various types and dimensions to fit different flange and pipeline systems.

- Ease of Maintenance: Facilitates quick assembly and disassembly, reducing downtime during maintenance.

- Cost-Effectiveness: Reusable and requires less material compared to traditional flanged joints.

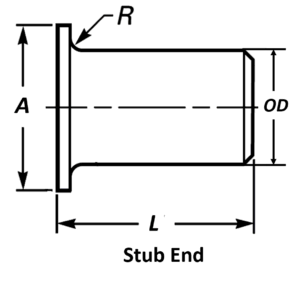

A234 WPB Stub End Dimensions

- Nominal Pipe Size (NPS): 1/2″ to 48″

- Wall Thickness: Sch 10, Sch 20, Sch 40, Sch 80, Sch 160, and XXS

- End Types: Beveled (BE), Plain (PE), or Threaded (TE)

| NOMINAL PIPE SIZE | LAP DIAMETER | OUTSIDE DIAMETER | LONG PATTERN LENGTH | SHORT PATTERN LENGTH | RADIUS | |

| Inch. | A | OD Min | OD Max | L | L | R |

| 1/2 | 35 | 22.8 | 20.5 | 76 | 51 | 3 |

| 3/4 | 43 | 28.1 | 25.9 | 76 | 51 | 3 |

| 1 | 51 | 35 | 32.6 | 102 | 51 | 3 |

| 1 1/4 | 64 | 43.6 | 41.4 | 102 | 51 | 5 |

| 1 1/2 | 73 | 49.9 | 47.5 | 102 | 51 | 6 |

| 2 | 92 | 62.4 | 59.5 | 152 | 64 | 8 |

| 2 1/2 | 105 | 75.3 | 72.2 | 152 | 64 | 8 |

| 3 | 127 | 91.3 | 88.1 | 152 | 64 | 10 |

| 3 1/2 | 140 | 104 | 100.8 | 152 | 76 | 10 |

| 4 | 157 | 116.7 | 113.5 | 152 | 76 | 11 |

| 5 | 186 | 144.3 | 140.5 | 203 | 76 | 11 |

| 6 | 216 | 171.3 | 167.5 | 203 | 89 | 13 |

| 8 | 270 | 222.1 | 218.3 | 203 | 102 | 13 |

| 10 | 324 | 277.2 | 272.3 | 254 | 127 | 13 |

| 12 | 381 | 328 | 323.1 | 254 | 152 | 13 |

| 14 | 413 | 359.9 | 354.8 | 305 | 152 | 13 |

| 16 | 470 | 411 | 405.6 | 305 | 152 | 13 |

| 18 | 533 | 462 | 456 | 305 | 152 | 13 |

| 20 | 584 | 514 | 507 | 305 | 152 | 13 |

| 22 | 641 | 565 | 558 | 305 | 152 | 13 |

| 24 | 692 | 616 | 609 | 305 | 152 | 13 |

Pipe Fitting Tolerance

| NOMINAL PIPE SIZE | ALL FITTINGS | ALL FITTINGS | ALL FITTINGS | ELBOWS AND TEES | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | REDUCERS | CAPS |

| NPS | O.D. at Bevel (1), (2) | I.D. at End | Wall Thickness (3) | Centre-to-End Dimension A,B,C,M | Centre-to-Centre O | Back-to-Face K | Alignment of Ends U | Overall Length H | Overall Length E |

| (1), (3), (4) | |||||||||

| ½ to 2½ | 0.06 | 0.03 | Not less than 87.5% of nominal thickness | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| -0.03 | |||||||||

| 3 to 3 ½ | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 4 | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 5 to 8 | 0.09 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 | |

| -0.06 | |||||||||

| 10 to 18 | 0.16 | 0.12 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| -0.12 | |||||||||

| 20 to 24 | 0.25 | 0.19 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| -0.19 | |||||||||

| 26 to 30 | 0.25 | 0.19 | 0.12 | … | … | … | 0.19 | 0.38 | |

| -0.19 | |||||||||

| 32 to 48 | 0.25 | 0.19 | 0.19 | … | … | … | 0.19 | 0.38 | |

| -0.19 |

| NOMINAL PIPE SIZE NPS | ANGULARITY TOLERANCES | ANGULARITY TOLERANCES |

| Off Angle Q | Off Plane P | |

| ½ to 4 | 0.03 | 0.06 |

| 5 to 8 | 0.06 | 0.12 |

| 10 to 12 | 0.09 | 0.19 |

| 14 to 16 | 0.09 | 0.25 |

| 18 to 24 | 0.12 | 0.38 |

| 26 to 30 | 0.19 | 0.38 |

| 32 to 42 | 0.19 | 0.5 |

| 44 to 48 | 0.18 | 0.75 |

Manufacturing Process

Stub ends conforming to ASTM A234 WPB are manufactured through various processes to ensure high quality and reliability:

- Material Selection:

-

-

- Premium-grade carbon steel is selected for its strength and temperature resistance.

- Forging:

- The raw material is heated and shaped into the desired dimensions.

-

- Machining:

-

-

- Precision machining ensures accurate dimensions and smooth finishes.

- Heat Treatment:

- Normalizing or quenching and tempering enhance mechanical properties.

-

- Inspection and Testing:

-

- Each stub end undergoes rigorous testing, including:

- Dimensional checks

- Ultrasonic testing

- Hydrostatic testing

- Chemical composition analysis

- Each stub end undergoes rigorous testing, including:

Testing and Quality Assurance

To ensure the reliability and safety of ASTM A234 WPB Stub Ends, stringent quality control measures are implemented:

- Mechanical Testing:

-

-

- Tensile strength, yield strength, and elongation tests are conducted.

-

- Hydrostatic Testing:

-

-

- Verifies the ability to withstand high-pressure conditions.

-

- Non-Destructive Testing (NDT):

-

-

- Ultrasonic and radiographic tests identify internal flaws.

-

- Chemical Analysis:

-

-

- Confirms compliance with ASTM A234 WPB composition standards.

-

- Dimensional Inspection:

-

- Ensures accurate dimensions and compatibility with other piping components.

Advantages

- Reduced Costs:

-

-

- Stub ends paired with backing flanges are more economical compared to full-welded or traditional flanged joints.

-

- Enhanced Longevity:

-

-

- The reusable design minimizes the need for frequent replacements.

-

- Simplified Installation:

-

-

- Easy to align and assemble, reducing installation time.

-

- High Compatibility:

-

-

- Works seamlessly with various flange types and pipeline materials.

-

- Improved Maintenance:

-

- Ideal for systems requiring regular inspection and cleaning.

Conclusion

ASTM A234 WPB Stub End is a crucial component in modern piping systems, offering unmatched reliability, strength, and versatility. With its excellent performance under high-temperature and high-pressure conditions, it is the preferred choice across industries such as oil and gas, petrochemicals, power generation, and water treatment.

Reviews

There are no reviews yet.