ASTM A234 WPB Elbow

ASTM A234 WPB Elbow is an essential component in the piping industry, widely used to alter the flow direction in a pipeline system. Known for its durability, strength, and resistance to various environmental factors, this type of elbow is primarily made from carbon steel. It conforms to the ASTM A234 specification for wrought carbon steel and alloy steel fittings. This document delves into the key aspects of ASTM A234 WPB elbows, including their features, manufacturing process, applications, advantages, and technical specifications.

Key Features of ASTM A234 WPB Elbow

- Material Composition: Composed mainly of carbon steel with additional elements like manganese, phosphorus, sulfur, and silicon to enhance its properties.

- Temperature Resistance: It is suitable for both moderate and high-temperature services, making it versatile for various industrial applications.

- Pressure Handling: Capable of handling high-pressure environments due to its robust construction and material strength.

- Corrosion Resistance: Although primarily used for non-corrosive environments, ASTM A234 WPB elbows can resist certain levels of corrosion with proper coating or treatment.

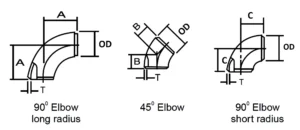

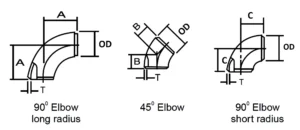

- Variety of Sizes and Angles: Available in standard angles such as 45°, 90°, and 180°, and in various sizes to fit diverse pipeline systems.

A234 WPB Elbow Dimensions

| NOMINAL PIPE SIZE |

OUTSIDE DIAMETER |

CENTER TO END |

| Inch. |

OD |

A |

B |

C |

| 1/2 |

21.3 |

38 |

16 |

– |

| 3/4 |

26.7 |

38 |

19 |

– |

| 1 |

33.4 |

38 |

22 |

25 |

| 1 1/4 |

42.2 |

48 |

25 |

32 |

| 1 1/2 |

48.3 |

57 |

29 |

38 |

| 2 |

60.3 |

76 |

35 |

51 |

| 2 1/2 |

73 |

95 |

44 |

64 |

| 3 |

88.9 |

114 |

51 |

76 |

| 3 1/2 |

101.6 |

133 |

57 |

89 |

| 4 |

114.3 |

152 |

64 |

102 |

| 5 |

141.3 |

190 |

79 |

127 |

| 6 |

168.3 |

229 |

95 |

152 |

| 8 |

219.1 |

305 |

127 |

203 |

| 10 |

273.1 |

381 |

159 |

254 |

| 12 |

323.9 |

457 |

190 |

305 |

| 14 |

355.6 |

533 |

222 |

356 |

| 16 |

406.4 |

610 |

254 |

406 |

| 18 |

457.2 |

686 |

286 |

457 |

| 20 |

508 |

762 |

318 |

508 |

| 22 |

559 |

838 |

343 |

559 |

| 24 |

610 |

914 |

381 |

610 |

| 26 |

660 |

991 |

406 |

660 |

| 28 |

711 |

1067 |

438 |

711 |

| 30 |

762 |

1143 |

470 |

762 |

| 32 |

813 |

1219 |

502 |

813 |

| 34 |

864 |

1295 |

533 |

864 |

| 36 |

914 |

1372 |

565 |

914 |

| 38 |

965 |

1448 |

600 |

965 |

| 40 |

1016 |

1524 |

632 |

1016 |

| 42 |

1067 |

1600 |

660 |

1067 |

| 44 |

1118 |

1676 |

695 |

1118 |

| 46 |

1168 |

1753 |

727 |

1168 |

| 48 |

1219 |

1829 |

759 |

1219 |

| All Dimensions are in mm |

Pipe Fitting Tolerance

| NOMINAL PIPE SIZE |

ALL FITTINGS |

ALL FITTINGS |

ALL FITTINGS |

ELBOWS AND TEES |

180 DEG RETURN BENDS |

180 DEG RETURN BENDS |

180 DEG RETURN BENDS |

REDUCERS |

CAPS |

| NPS |

O.D. at Bevel (1), (2) |

I.D. at End |

Wall Thickness (3) |

Centre-to-End Dimension A,B,C,M |

Centre-to-Centre O |

Back-to-Face K |

Alignment of Ends U |

Overall Length H |

Overall Length E |

| (1), (3), (4) |

| ½ to 2½ |

0.06 |

0.03 |

Not less than 87.5% of nominal thickness |

0.06 |

0.25 |

0.25 |

0.03 |

0.06 |

0.12 |

| -0.03 |

| 3 to 3 ½ |

0.06 |

0.06 |

0.06 |

0.25 |

0.25 |

0.03 |

0.06 |

0.12 |

| 4 |

0.06 |

0.06 |

0.06 |

0.25 |

0.25 |

0.03 |

0.06 |

0.12 |

| 5 to 8 |

0.09 |

0.06 |

0.06 |

0.25 |

0.25 |

0.03 |

0.06 |

0.25 |

| -0.06 |

| 10 to 18 |

0.16 |

0.12 |

0.09 |

0.38 |

0.25 |

0.06 |

0.09 |

0.25 |

| -0.12 |

| 20 to 24 |

0.25 |

0.19 |

0.09 |

0.38 |

0.25 |

0.06 |

0.09 |

0.25 |

| -0.19 |

| 26 to 30 |

0.25 |

0.19 |

0.12 |

… |

… |

… |

0.19 |

0.38 |

| -0.19 |

| 32 to 48 |

0.25 |

0.19 |

0.19 |

… |

… |

… |

0.19 |

0.38 |

| -0.19 |

| NOMINAL PIPE SIZE NPS |

ANGULARITY TOLERANCES |

ANGULARITY TOLERANCES |

| |

Off Angle Q |

Off Plane P |

| ½ to 4 |

0.03 |

0.06 |

| 5 to 8 |

0.06 |

0.12 |

| 10 to 12 |

0.09 |

0.19 |

| 14 to 16 |

0.09 |

0.25 |

| 18 to 24 |

0.12 |

0.38 |

| 26 to 30 |

0.19 |

0.38 |

| 32 to 42 |

0.19 |

0.5 |

| 44 to 48 |

0.18 |

0.75 |

Manufacturing Process

-

-

- High-quality carbon steel is chosen as the raw material.

-

-

- The material is heated to a specific temperature and shaped into the desired elbow form.

-

-

- Normalizing or annealing is performed to refine the grain structure and enhance mechanical properties.

- Beveling:

- The ends of the elbows are beveled to facilitate welding during installation.

-

-

- Strict quality checks are conducted to ensure compliance with ASTM A234 standards.

-

- Elbows may undergo anti-corrosion treatments like galvanization or coating for extended durability

Advantages of ASTM A234 WPB Elbow

-

-

- Withstands extreme temperatures and pressures, ensuring long service life.

-

-

- Suitable for a wide range of industries and applications.

-

-

- Offers a high-performance solution at a reasonable cost.

-

-

- Designed for seamless integration into existing pipelines.

-

- Available in various sizes, angles, and radii to meet specific requirements.

Advantages

-

-

- Withstands extreme temperatures and pressures, ensuring long service life.

-

-

- Suitable for a wide range of industries and applications.

-

-

- Offers a high-performance solution at a reasonable cost.

-

-

- Designed for seamless integration into existing pipelines.

-

- Available in various sizes, angles, and radii to meet specific requirements.

Reviews

There are no reviews yet.