ASTM A105 Threaded Flange

ASTM A105 Threaded Flange are forged carbon steel flanges designed for low-pressure and non-welded piping applications. They feature internal threads that allow pipes to be joined without welding, making them ideal for flammable, explosive, or hazardous environments where welding is not possible or permitted. A105 threaded flanges are widely used in oil & gas, chemical processing, power plants, and general industrial piping systems requiring secure, leak-resistant threaded connections.

These flanges provide durable strength, corrosion resistance, and ease of installation for moderate temperature and pressure applications.

Key Features

- Manufactured from high-strength forged carbon steel

- No-weld installation — suitable for hazardous environments

- Ideal for low-pressure & small-bore piping systems

- Provides leak-resistant threaded connection

- Compatible with NPT/BSPT/BSPP threaded pipes

- Available in RF, FF & RTJ facing types

- ANSI/ASME & MSS compliant manufacturing

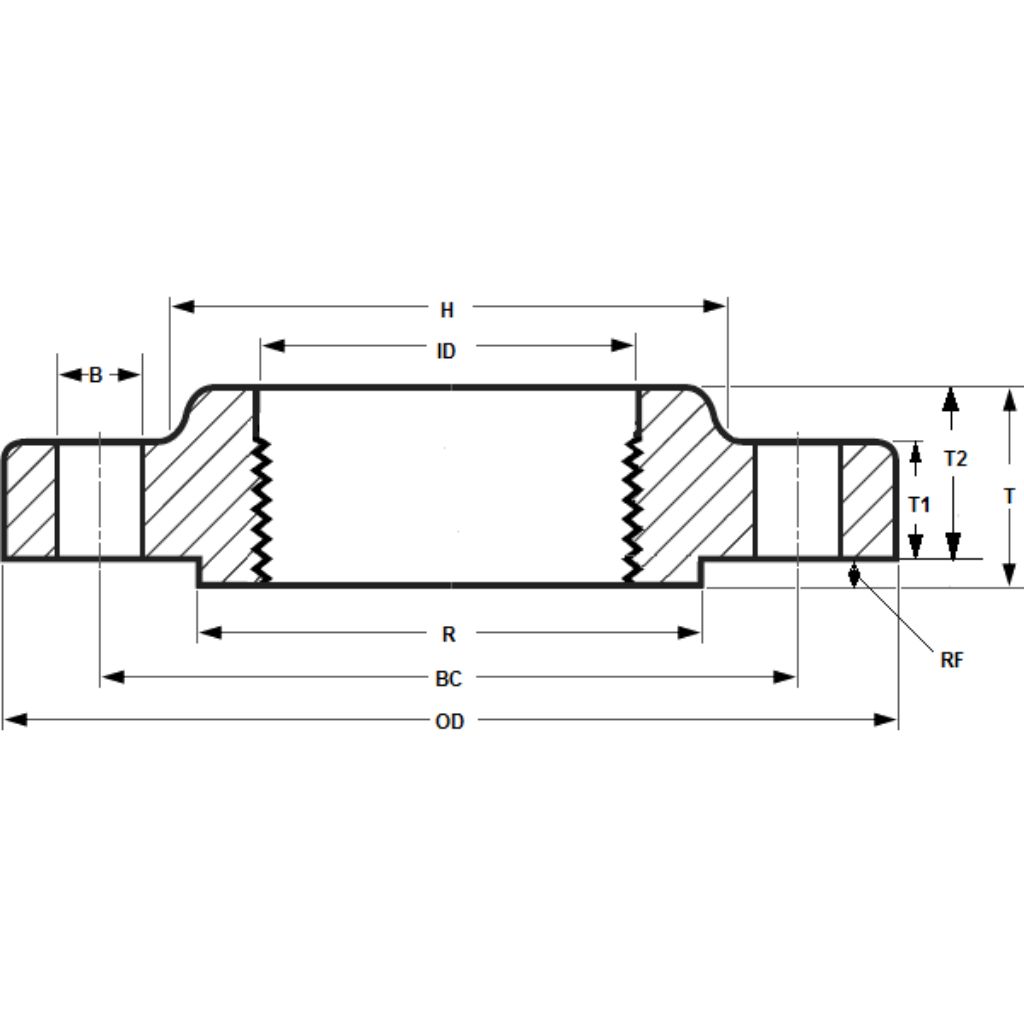

Threaded Flange Dimensions

| Nominal pipe size |

Thread density |

Thread Pitch |

Hand-Tight Engagement | Effective Thread | Overall Length |

Actual Outside Diameter OD |

Tap drill | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | mm | Length | Turns | Diameter | Length | Turns | Diameter | inch | mm | inch | mm | |||

| inch | inch⁻¹ | inch | mm | inch | – | inch | inch | – | inch | inch | inch | mm | inch | mm |

| 1/16 | 27 | 0.03703704 | 0.9407 | 0.1600 | 4.32 | 0.28118 | 0.2611 | 7.05 | 0.2875 | 0.3896 | 0.313 | 7.95 | – | – |

| 1/8 | 27 | 0.03703704 | 0.9407 | 0.1615 | 4.36 | 0.37360 | 0.2639 | 7.13 | 0.38000 | 0.3924 | 0.405 | 10.287 | 0.339 | 8.6106 |

| 1/4 | 18 | 0.05555555 | 1.41111 | 0.2278 | 4.10 | 0.49163 | 0.4018 | 7.23 | 0.50250 | 0.5946 | 0.540 | 13.716 | 7/16 | 11.113 |

| 3/8 | 18 | 0.05555555 | 1.41111 | 0.2400 | 4.32 | 0.62701 | 0.4078 | 7.34 | 0.63750 | 0.6006 | 0.675 | 17.145 | 37/64 | 14.684 |

| 1/2 | 14 | 0.07142857 | 1.8143 | 0.3200 | 4.48 | 0.77843 | 0.5337 | 7.47 | 0.79178 | 0.7815 | 0.840 | 21.3360 | 23/32 | 18.2563 |

| 3/4 | 14 | 0.07142857 | 1.8143 | 0.3390 | 4.75 | 0.98887 | 0.5457 | 7.64 | 1.00178 | 0.7935 | 1.050 | 26.6700 | 59/64 | 23.4156 |

| 3/4 | 11 1/2 | 0.08695652 | 2.2087 | 0.4000 | 4.60 | 1.23863 | 0.6828 | 7.85 | 1.25631 | 0.9845 | 1.315 | 33.4010 | 1 5/32 | 29.3688 |

| 1 1/4 | 11 1/2 | 0.08695652 | 2.2087 | 0.4200 | 4.83 | 1.58338 | 0.7068 | 8.13 | 1.60131 | 1.0085 | 1.660 | 42.1640 | 1 1/2 | 38.1000 |

| 1 1/2 | 11 1/2 | 0.08695652 | 2.2087 | 0.4200 | 4.83 | 1.82234 | 0.7235 | 8.32 | 1.84131 | 1.0252 | 1.900 | 48.2600 | 1 47/64 | 44.0531 |

| 2 | 11 1/2 | 0.08695652 | 2.2087 | 0.4360 | 5.01 | 2.29627 | 0.7565 | 8.70 | 2.31630 | 1.0582 | 2.375 | 60.3250 | 2 7/32 | 56.3563 |

| 2 1/2 | 8 | 0.12500000 | 3.1750 | 0.6820 | 5.46 | 2.76216 | 1.1375 | 9.10 | 2.79063 | 1.5712 | 2.875 | 73.0250 | 2 5/8 | 66.6750 |

| 3 | 8 | 0.12500000 | 3.1750 | 0.7660 | 6.13 | 3.38850 | 1.2000 | 9.60 | 3.41563 | 1.6337 | 3.500 | 89.9000 | 3 1/4 | 82.5500 |

| 3 1/2 | 8 | 0.12500000 | 3.1750 | 0.8210 | 6.57 | 3.88881 | 1.2500 | 10.00 | 3.91563 | 1.6837 | 4.000 | 101.6000 | 3 3/4 | 95.2500 |

| 4 | 8 | 0.12500000 | 3.1750 | 0.8440 | 6.75 | 4.38713 | 1.3000 | 10.40 | 4.41563 | 1.7337 | 4.500 | 114.3000 | 4 1/4 | 107.9500 |

| 5 | 8 | 0.12500000 | 3.1750 | 0.9370 | 7.50 | 5.44929 | 1.4063 | 11.25 | 5.47863 | 1.8400 | 5.563 | 141.3002 | 5 9/32 | 134.1438 |

| 6 | 8 | 0.12500000 | 3.1750 | 0.9580 | 7.66 | 6.50597 | 1.5125 | 12.10 | 6.54063 | 1.9462 | 6.625 | 168.2750 | 6 11/32 | 161.1313 |

| 6 | 8 | 0.12500000 | 3.1750 | 0.9580 | 7.66 | 6.50597 | 1.5125 | 12.10 | 6.54063 | 1.9462 | 6.625 | 168.2750 | 6 11/32 | 161.1313 |

| 8 | 8 | 0.12500000 | 3.1750 | 1.0630 | 8.50 | 8.50003 | 1.7125 | 13.70 | 8.54063 | 2.1462 | 8.625 | 219.0750 | – | – |

| 10 | 8 | 0.12500000 | 3.1750 | 1.2100 | 9.68 | 10.62094 | 1.9250 | 15.40 | 10.66563 | 2.3587 | 10.750 | 273.0500 | – | – |

| 12 | 8 | 0.12500000 | 3.1750 | 1.3600 | 10.88 | 12.61781 | 2.1250 | 17.00 | 12.66563 | 2.5587 | 12.750 | 323.8500 | – | – |

| 14 | 8 | 0.12500000 | 3.1750 | 1.5620 | 12.50 | 13.87263 | 2.2500 | 18.00 | 13.91563 | 2.6837 | 14.000 | 355.6000 | – | – |

| 16 | 8 | 0.12500000 | 3.1750 | 1.8120 | 14.50 | 15.87575 | 2.4500 | 19.60 | 15.91563 | 2.8837 | 16.000 | 406.4000 | – | – |

| 18 | 8 | 0.12500000 | 3.1750 | 2.0000 | 16.00 | 17.87500 | 2.6500 | 21.20 | 17.91563 | 3.0837 | 18.000 | 457.2000 | – | – |

| 20 | 8 | 0.12500000 | 3.1750 | 2.1250 | 17.00 | 19.87031 | 2.8500 | 22.80 | 19.91563 | 3.2837 | 20.000 | 508.0000 | – | – |

| 24 | 8 | 0.12500000 | 3.1750 | 2.3750 | 19.00 | 23.86094 | 3.2500 | 26.00 | 23.91563 | 3.6837 | 24.000 | 609.6000 | – | – |

Chemical Composition (ASTM A105)

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.35 max |

| Manganese (Mn) | 0.60 – 1.05 |

| Silicon (Si) | 0.10 – 0.35 |

| Phosphorus (P) | 0.035 max |

| Sulfur (S) | 0.040 max |

| Copper (Cu) | 0.40 max |

| Nickel (Ni) | 0.40 max |

| Chromium (Cr) | 0.30 max |

| Molybdenum (Mo) | 0.12 max |

| Vanadium (V) | 0.08 max |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 485 MPa (70 ksi) |

| Yield Strength | ≥ 250 MPa (36 ksi) |

| Elongation | ≥ 22% |

| Hardness | ≤ 187 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | ~1450°C |

| Elastic Modulus | 200 GPa |

| Thermal Conductivity | 60.5 W/m-K |

Types of ASTM A105 Threaded Flanges

- Standard Threaded (Screwed) Flange

- Threaded RTJ Flange

- Threaded Orifice Flange

- Threaded Reducing Flange

- Threaded Raised Face (RF) Flange

- Threaded Flat Face (FF) Flange

Applications

- Oil & Gas Pipelines

- Chemical & Petrochemical Plants

- Power Generation & Boilers

- Firefighting & Water Supply Lines

- Hazardous & Explosive Zones

- Low-pressure utility services

- Small-bore piping & temporary installations

Reviews

There are no reviews yet.