ASTM A403 WP304

ASTM A403 WP304H Stainless Steel Pipe Fittings

ASTM A403 WP304H Pipe Fittings are high-temperature austenitic stainless steel fittings manufactured from grade 304H — a high-carbon modification of 304 stainless steel. Engineered for enhanced strength at elevated temperatures, WP304H fittings are widely used in boilers, heat exchangers, power generation plants, refining units, and high-temperature fluid processing lines.

With excellent mechanical properties, superior corrosion and oxidation resistance, and outstanding formability, ASTM A403 WP304H is a preferred choice for high-pressure & high-temperature piping systems.

Key Features

High carbon content for improved high-temperature strength

Excellent resistance to oxidation & scaling up to 870°C

Good corrosion resistance in a wide range of environments

Superior weldability and formability

Excellent creep and stress-rupture strength

Ideal for high-temperature & high-pressure fluid transfer

Long service life & durability in harsh industrial conditions

Specifications

| Specification | Details |

|---|---|

| Standard | ASTM A403 |

| Grade | WP304H |

| Material | Austenitic Stainless Steel |

| Manufacturing Types | Seamless / Welded / ERW |

| Sizes | ½” to 48″ (DN15–DN1200) |

| Standards | ASME B16.9 / B16.11 / MSS-SP-43 |

| Pressure Rating | SCH 5S to SCH XXS |

| Forms | Butt-Weld, Socket Weld, Threaded |

| Surface Finish | Mill Finished / Pickled & Passivated |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | S30409 |

| WNR | 1.4948 |

| EN | 1.4948 |

| JIS | SUS 304H |

| DIN | X5CrNi18-10 (High-Carbon Variant) |

| BS | 304S51 |

Available Sizes

Butt-Weld Fittings: ½” – 48″

Socket Weld / Threaded Fittings: ⅛” – 4″

Schedules: SCH 5S, 10S, 20, 40, 80, 120, 160, XXS

Custom sizes available on request.

Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.04 – 0.10 |

| Chromium (Cr) | 18.0 – 20.0 |

| Nickel (Ni) | 8.0 – 11.0 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 0.75 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Nitrogen (N) | ≤ 0.10 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 515 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 35% |

| Hardness | ≤ 217 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | 8.0 g/cm³ |

| Melting Point | 1400 – 1455°C |

| Thermal Conductivity | 16.2 W/m-K (100°C) |

| Electrical Resistivity | 0.72 µΩ-m (20°C) |

| Modulus of Elasticity | 193 GPa |

Types of ASTM A403 WP304H Fittings

ASTM A403 WP304H Elbow

ASTM A403 WP304H Tee

ASTM A403 WP304H Reducers

ASTM A403 WP304H Caps

ASTM A403 WP304H Cross Fittings

ASTM A403 WP304H Nipples

ASTM A403 WP304H Couplings

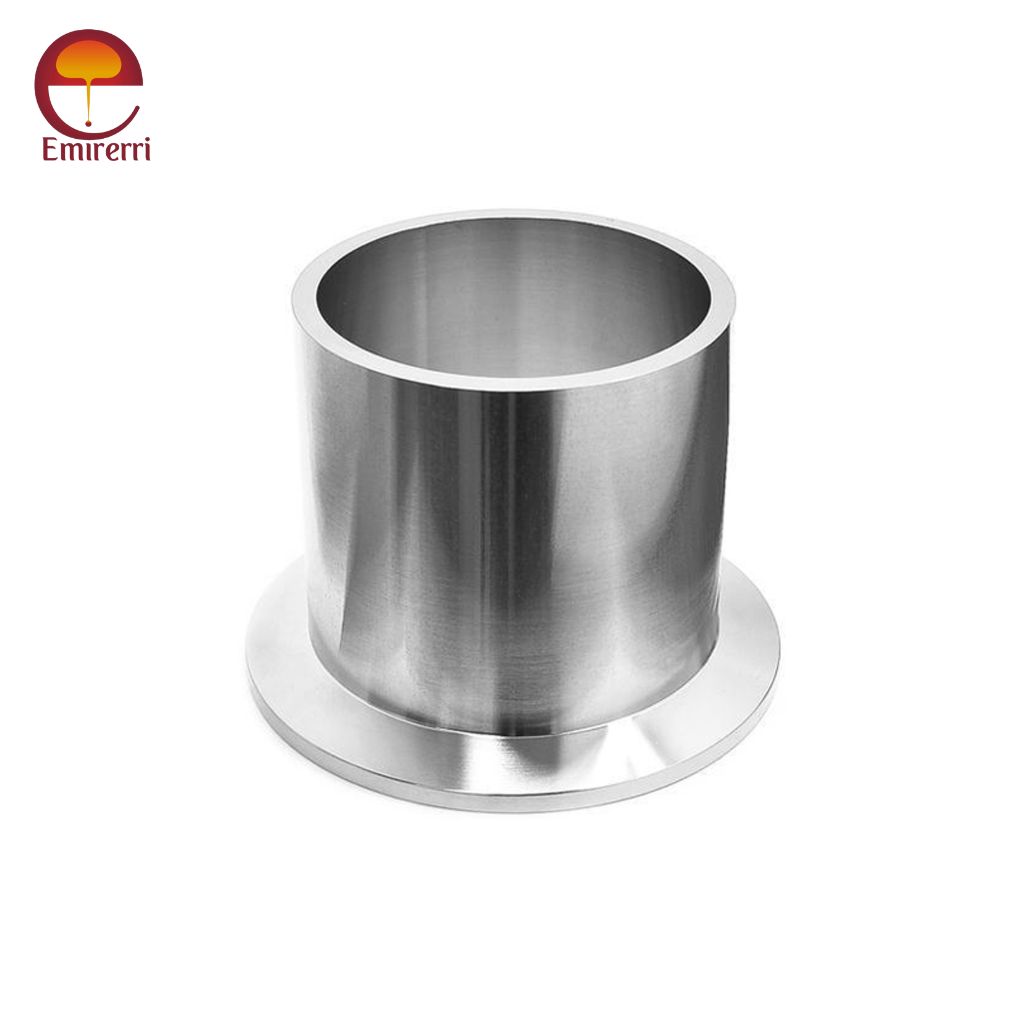

ASTM A403 WP304H Stub Ends

Corrosion Resistance

ASTM A403 WP304H provides:

Excellent resistance to atmospheric & oxidizing environments

Good performance in nitric acid & organic chemicals

Resistance to intergranular corrosion due to controlled carbon content

Not recommended for chloride-rich media where 316/316L is preferred

Heat Resistance

Sustains elevated temperatures up to 870°C

Excellent creep and stress-rupture strength

Suitable for continuous service in furnace & boiler environments

Heat Treatment

Solution Annealed: 1040–1100°C followed by water quenching

No hardening by heat treatment (austenitic structure)

Welding

Excellent weldability using TIG/MIG/SMAW

Low-carbon filler recommended to reduce carbide precipitation

Preheat & post-weld heat treatment not required in most cases

Fabrication

Good machinability & formability

Easily cold & hot worked

Recommended to perform pickling & passivation after fabrication

Applications

Petrochemical & Refinery Plants

Thermal & Power Generation Units

Heat Exchangers & Boilers

Super Heaters & Pressure Vessels

High-Temperature Steam & Gas Lines

Chemical Processing Equipment

Oil & Gas Transmission Pipelines

Food & Pharmaceutical Industries