ASTM A403 WP316H

ASTM A403 WP316H Pipe Fittings

ASTM A403 WP316H is a premium grade of austenitic stainless-steel butt-weld pipe fittings, designed specifically for high-temperature and high-pressure service conditions. The elevated carbon content in 316H enhances its high-temperature strength, creep resistance, and mechanical performance, making it ideal for industrial applications where sustained exposure to elevated temperatures is common.

These fittings are widely used in chemical processing, petrochemical plants, refineries, thermal power plants, and high-temperature steam services due to their exceptional corrosion resistance and thermal stability.

Key Features

Superior creep and stress-rupture strength at elevated temperatures

Excellent resistance to corrosion and oxidation

Designed for high-temperature applications

Resistant to sulfur-bearing environments

Suitable for welding and forming

Exceptional resistance to chlorides, reducing pitting and crevice corrosion risks

Long-lasting performance in harsh industrial environments

Technical Specification

| Standard | ASTM A403 / ASME SA403 |

|---|---|

| Grade | WP316H |

| Material | Austenitic Stainless Steel |

| Manufacturing Type | Seamless / Welded / ERW |

| Form | Buttweld Pipe Fittings |

| Size Range | ½” to 48” |

| Wall Thickness | SCH 10S to SCH XXS |

| Standards (Fittings) | ASME B16.9, ASME B16.28, MSS-SP-43 |

| Ends | Beveled, Plain End |

Equivalent Grades

| Standard | Grade |

|---|---|

| ASTM / ASME | A403 / SA403 WP316H |

| DIN | X5CrNiMo17-12-2 (similar to 316H chemistry) |

| UNS | S31609 |

| EN | 1.4401 / 1.4404 (reference) |

Available Sizes

Pipe Fittings Size: 1/2” – 48”

Thickness: SCH 10S, SCH 40S, SCH 80S, SCH 160, XXS

Types: Seamless / Welded / Fabricated

Chemical Composition

| Element | % Composition |

|---|---|

| Carbon (C) | 0.04 – 0.10 |

| Chromium (Cr) | 16.0 – 18.0 |

| Nickel (Ni) | 10.0 – 14.0 |

| Molybdenum (Mo) | 2.00 – 3.00 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Nitrogen (N) | ≤ 0.10 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 515 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 35% |

| Hardness | ≤ 217 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | 8.0 g/cm³ |

| Melting Point | 1375 – 1400°C |

| Thermal Conductivity | 16.3 W/m-K (at 100°C) |

| Electrical Resistivity | 740 nΩ-m (at 20°C) |

| Modulus of Elasticity | 193 GPa |

Types of ASTM A403 WP316H Pipe Fittings

ASTM A403 WP316H Elbow

ASTM A403 WP316H Tee

ASTM A403 WP316H Reducers

ASTM A403 WP316H Caps

ASTM A403 WP316H Cross Fittings

ASTM A403 WP316H Nipples

ASTM A403 WP316H Couplings

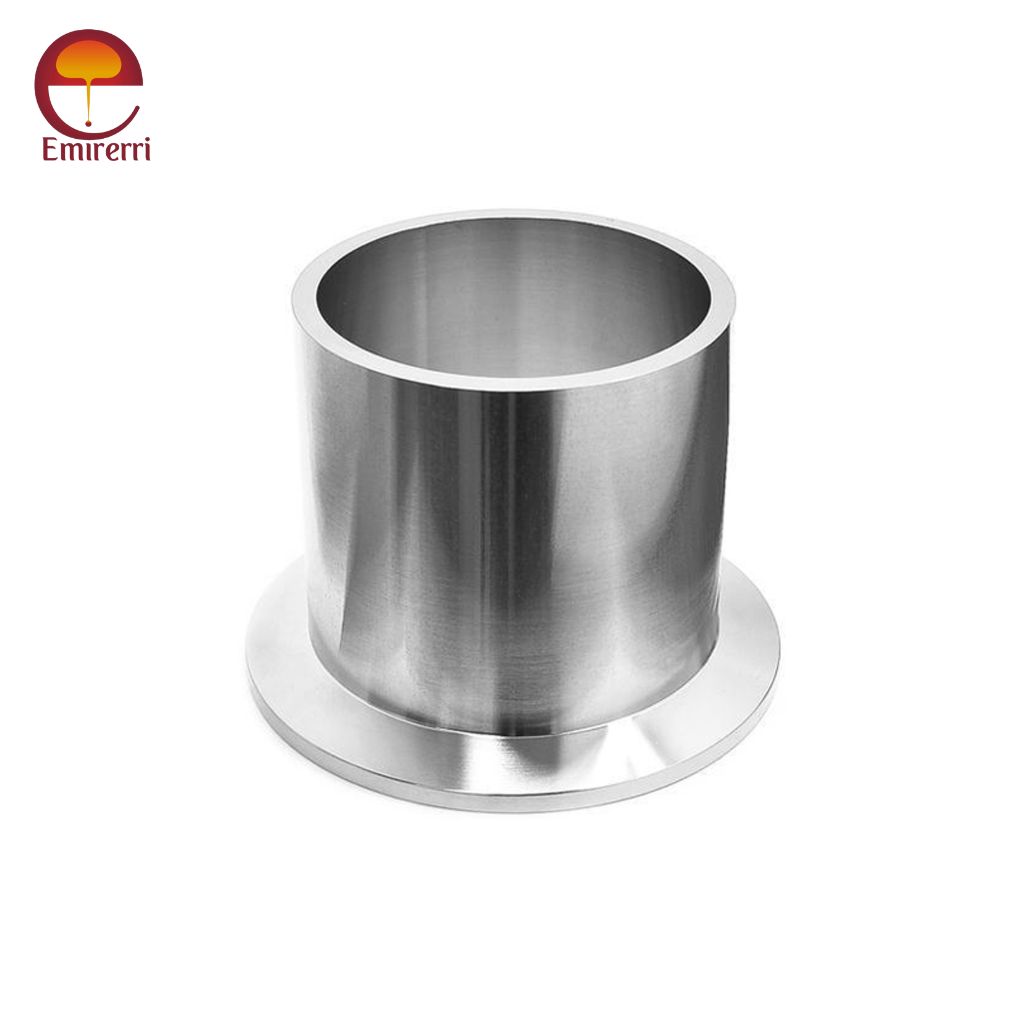

ASTM A403 WP316H Stub Ends

Corrosion Resistance

Excellent resistance to chloride-induced pitting

Highly resistant to acidic and corrosive media

Superior performance in marine and chemical environments

Suitable for high-temperature corrosive atmospheres

Heat Resistance

High resistance to oxidation up to 870°C

Suitable for continuous exposure in 550°C – 650°C temperature range

Maintains strength under creep-stress conditions

Heat Treatment

Solution Annealing: 1010°C – 1120°C

Rapid cooling to retain corrosion resistance and mechanical strength

Welding

Excellent weldability with standard fusion methods

Prefer low heat input

Post-weld annealing recommended for heavy-section welds

Fabrication

Easily machined, formed, and fabricated

Requires sharp tools and slow speeds for machining

Avoid prolonged exposure to carbide-precipitation ranges

Applications

Chemical & Petrochemical Plants

Oil & Gas Industry

Refineries

Power Generation & Thermal Plants

High-Temperature Steam Lines

Fertilizer & Pharmaceutical Industry

Heat Exchangers & Boiler Equipment

Food & Beverage Processing

Marine Environments