ASTM A403 WP347H

ASTM A403 WP347H Pipe Fittings

ASTM A403 WP347H is a high-carbon, niobium-stabilized austenitic stainless steel grade used for high-temperature and high-pressure applications. The “H” grade provides enhanced creep strength, stress-rupture resistance, and long-term stability in elevated-temperature environments.

Stabilized with niobium (columbium), WP347H offers superior resistance to carbide precipitation and intergranular corrosion, especially after welding. These properties make it ideal for petrochemical, refinery, power generation, furnace, steam piping, and thermal equipment applications.

Key Features

Niobium stabilized for excellent intergranular corrosion resistance

High-carbon version for superior high-temperature strength

Excellent creep strength & stress-rupture resistance

Ideal for 600°C – 900°C continuous high-temperature service

Improved weldability and structural stability

Strong resistance to oxidation, scaling & carburizing media

Long service life in aggressive thermal & corrosive conditions

Technical Specification

| Specification | Details |

|---|---|

| Standard | ASTM A403 / ASME SA403 |

| Grade | WP347H |

| UNS | S34709 |

| Material | Niobium Stabilized Austenitic Stainless Steel |

| Size Range | ½” to 48” |

| Thickness | SCH 10S – SCH XXS |

| Forms | Seamless / Welded / Fabricated |

| Dimensional Standards | ASME B16.9 / B16.28 / MSS-SP-43 |

| Ends | Beveled / Plain End |

Equivalent Grades

| Standard | Grade |

|---|---|

| ASTM / ASME | A403 / SA403 WP347H |

| UNS | S34709 |

| EN | 1.4912 |

| DIN | X8CrNiNb18-10 |

Available Sizes

1/2” to 48”

Thickness: SCH 10S – SCH XXS

Options: Seamless / Welded / Fabricated

Chemical Composition

| Element | % |

|---|---|

| Carbon (C) | 0.04 – 0.10 |

| Chromium (Cr) | 17.0 – 19.0 |

| Nickel (Ni) | 9.0 – 13.0 |

| Niobium (Nb + Ta) | ≥ 10 × C% (0.10 – 1.10) |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorous (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Nitrogen (N) | ≤ 0.10 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 515 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 40% |

| Hardness | ≤ 217 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.9 g/cm³ |

| Melting Range | 1400 – 1455°C |

| Thermal Conductivity | 16 W/m-K |

| Specific Heat | 500 J/kg-K |

| Modulus of Elasticity | ~193 GPa |

Types of WP347H Fittings

ASTM A403 WP347H Elbow

ASTM A403 WP347H Tee

ASTM A403 WP347H Reducers

ASTM A403 WP347H Caps

ASTM A403 WP347H Cross Fittings

ASTM A403 WP347H Nipples

ASTM A403 WP347H Couplings

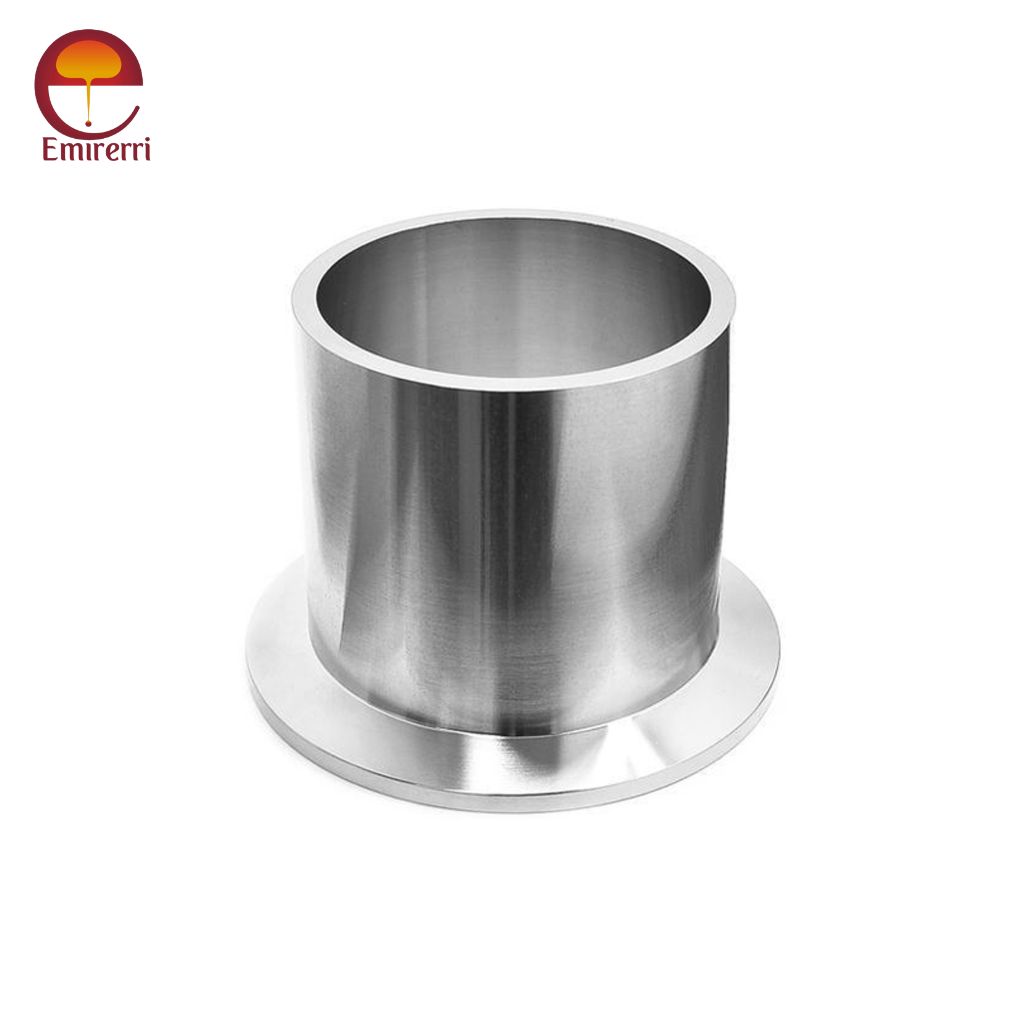

ASTM A403 WP347H Stub Ends

Corrosion Resistance

Excellent resistance to intergranular corrosion post-welding

Superior protection against carbide precipitation

Resistant to oxidizing & corrosive atmospheres

Performs well in chloride & acidic media

Heat Resistance

Reliable performance in up to 900°C service

High-temperature strength & creep resistance

Performs well in thermal cycling environments

Suitable for steam & furnace systems

Heat Treatment

| Process | Details |

|---|---|

| Solution Annealing | 1010°C – 1120°C |

| Cooling | Rapid air / water quench |

Welding

Excellent weldability with TIG, MIG, SMAW

Niobium stabilization prevents sensitization

No preheat required

Recommended fillers — ER347 / E347

Fabrication

Good formability & machinability

Cold forming followed by annealing recommended

Use carbide tooling for machining

Applications

Petrochemical & Refinery Piping Systems

Boilers, Superheaters & Heat Exchangers

Power Generation & Steam Lines

Chemical Processing Equipment

Furnace Components & Thermal Plants

Oil & Gas Pipelines

Exhaust & High-Temp Gas Handling Systems