ASTM A815 CR429

ASTM A815 CR429 Wrought Ferritic Stainless Steel Pipe Fittings

ASTM A815 CR429 refers to wrought ferritic stainless steel pipe fittings manufactured in accordance with ASTM A815 / A815M standards. The CR class signifies fittings produced to MSS SP-43 requirements and suitable for corrosive and moderate-temperature environments.

These fittings are made from UNS S42900 (Type 429) stainless steel — a ferritic stainless alloy containing approx. 14.0–18.0% chromium, offering excellent corrosion resistance, scale resistance, and dimensional stability. CR429 fittings are ideal for industries demanding durable, corrosion-resistant piping solutions at an economical cost compared to austenitic alloys.

Key Features

Manufactured from UNS S42900 ferritic stainless steel

Good oxidation & scaling resistance at elevated temperatures

Enhanced chloride-related corrosion resistance

Excellent resistance to stress corrosion cracking

Economical alternative to 304/316 stainless grades in many environments

Stable structure with low carbon for weldability & formability

Good performance in mild acids, alkalis & atmospheric conditions

Specification

| Property | Detail |

|---|---|

| Standard | ASTM A815 / A815M |

| Grade | CR429 |

| Material Type | Ferritic Stainless Steel |

| UNS | S42900 |

| Equivalent | Type 429 Stainless Steel |

| Class | CR (to MSS SP-43) |

| Form | Wrought Welded Pipe Fittings |

| Size Range | ½” to 48” (DN15 to DN1200) |

| Thickness Range | SCH 10 – SCH XXS |

| End Connection | Bevelled for Butt-Weld |

| Surface | Mill Finish / Pickled & Passivated |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | S42900 |

| AISI | 429 |

| ASTM | A815 CR429 |

| EN | Comparable to 1.4016 / Similar ferritic grade |

| JIS | Equivalent ferritic stainless reference |

Note: Type 429 is a ferritic stainless steel similar to Type 430 with better heat resistance.

Available Sizes

Outside Diameter: ½” to 48”

Thickness: SCH 10, SCH 40, SCH 80, SCH 160, XXS

Available in Elbows, Tees, Reducers, Caps, Stub Ends

Chemical Composition

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 14.0 – 18.0 |

| Carbon (C) | ≤ 0.12 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Nickel (Ni) | ≤ 0.5 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 415 MPa |

| Yield Strength | ≥ 275 MPa |

| Elongation | ≥ 20% |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.7 – 7.8 g/cm³ |

| Melting Point | 1420°C – 1510°C |

| Modulus of Elasticity | ~200 GPa |

| Thermal Conductivity | Higher than 300-series stainless |

| Expansion Coefficient | Lower than austenitic stainless steel |

Types of ASTM A815 CR429 Fittings

ASTM A815 CR429 Elbow

ASTM A815 CR429 Tee

ASTM A815 CR429 Reducers

ASTM A815 CR429 Caps

ASTM A815 CR429 Cross Fittings

ASTM A815 CR429 Nipples

ASTM A815 CR429 Couplings

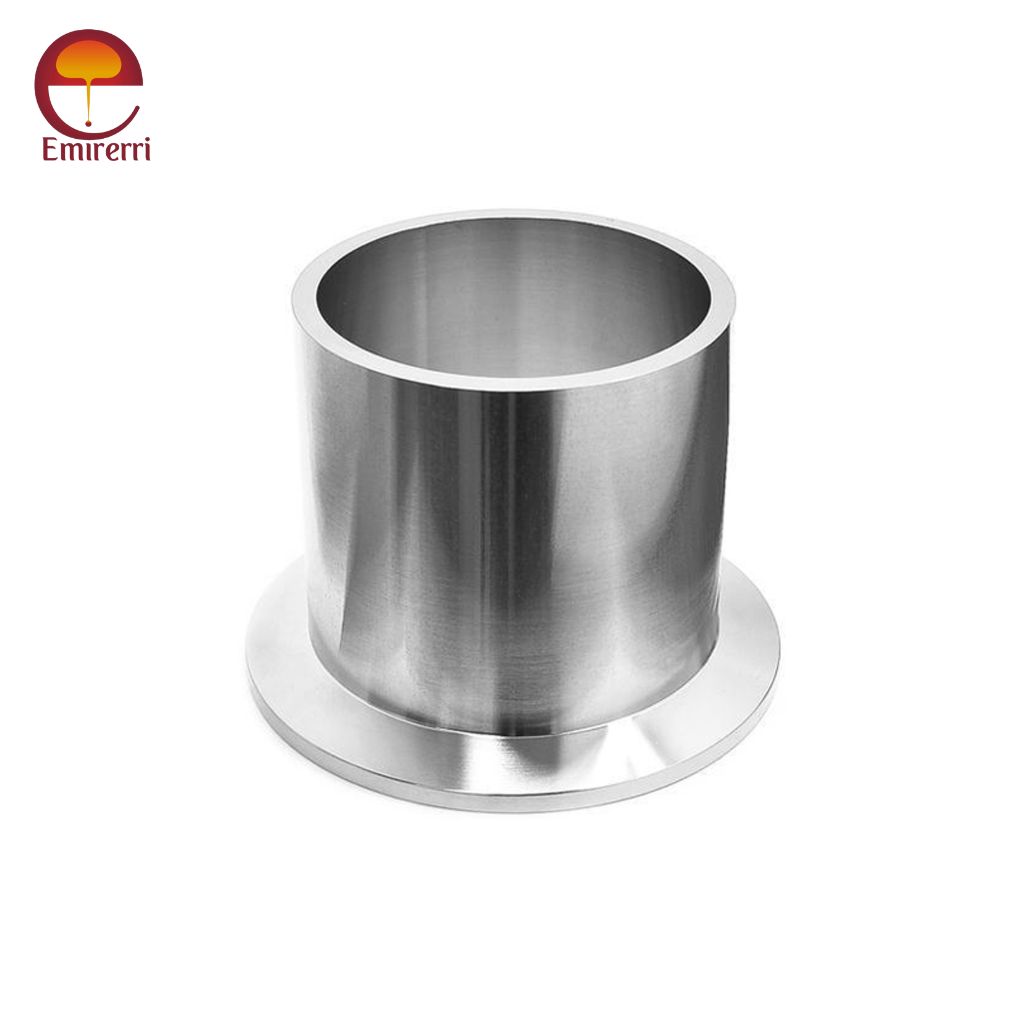

ASTM A815 CR429 Stub Ends

Corrosion Resistance

Strong resistance to atmospheric & freshwater corrosion

Good resistance to mild acids, alkali & organics

Better chloride pitting resistance than 400-series stainless

Superior stress-corrosion cracking resistance vs austenitic steels

Heat Resistance

Good oxidation resistance up to ~800–850°C

Suitable for heat exchangers, heaters, exhaust systems

Excellent scaling resistance in intermittent high temperatures

Heat Treatment

Annealing: 780°C – 900°C, followed by air cooling

Stress-relief heat treatment may enhance service performance

Avoid rapid quenching to prevent brittleness

Welding

Suitable for standard ferritic stainless steel welding processes

Recommended filler: matching stainless grade

Pre-heat: not generally needed

Post-weld annealing beneficial for critical applications

Fabrication

Good machinability & formability

Avoid excessive cold forming without intermediate heating

Can be cut, formed, and welded with conventional methods

Applications

Chemical Processing Equipment

Food & Dairy Piping (non-chloride environments)

Heat-resistant Ducts & Exhaust Systems

Power Plant & Boiler Components

Industrial Heat Exchangers

Water Treatment & Filtration Systems

Architectural & Structural Piping

Automotive & Industrial Muffler Systems