ASTM A815 WP430

ASTM A815 WP430 Wrought Stainless Steel Pipe Fittings

ASTM A815 WP430 refers to wrought ferritic stainless steel pipe fittings manufactured under ASTM A815 specification. These fittings are produced from UNS S43000 (Grade 430) stainless steel, a corrosion-resistant ferritic alloy containing about 16% chromium, offering strong resistance to mild corrosive environments, oxidation, and heat scaling.

ASTM A815 WP430 fittings are used in applications where moderate corrosion resistance, thermal stability, and cost-effectiveness are required. They are suitable for industrial exhaust systems, flue gas systems, heat exchangers, food industry piping, and decorative architectural applications.

With excellent resistance to stress corrosion cracking and oxidation at elevated temperatures, WP430 is a preferred choice in chemical plants, refinery systems, food processing equipment, and thermal processing units.

Key Features

Made from UNS S43000 ferritic stainless steel

Good resistance to oxidation & scaling at high temperatures

Better stress-corrosion cracking resistance vs. austenitic grades

Excellent formability & moderate toughness

Cost-effective alternative to 304 stainless steel

Magnetic ferritic stainless structure

Stable microstructure with low expansion under heat

Specification

| Property | Details |

|---|---|

| Standard | ASTM A815 / A815M |

| Grade | WP430 |

| Material Type | Ferritic Stainless Steel |

| UNS | S43000 |

| Equivalent | AISI 430 Stainless Steel |

| Manufacturing Process | Welded / Seamless |

| Form | Butt-Weld Pipe Fittings |

| Sizes | ½” to 48” (DN15 – DN1200) |

| Thickness | SCH 10 to SCH XXS |

| End Finish | Bevelled (BW) |

| Surface Finish | Mill Finish / Pickled & Passivated |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | S43000 |

| ASTM | A815 WP430 |

| AISI | 430 |

| EN / W.Nr | 1.4016 |

| JIS | SUS430 |

Available Sizes

Pipe Size: ½” to 48”

Wall Thickness: SCH 10 – SCH XXS

Configurations: Elbows, tees, reducers, caps, stub ends, crosses

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 16.0 – 18.0 |

| Carbon (C) | ≤ 0.12 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Nickel (Ni) | ≤ 0.5 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 450 MPa |

| Yield Strength | ≥ 280 MPa |

| Elongation | ≥ 20% |

| Hardness | ≤ 202 HBW |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.7 – 7.8 g/cm³ |

| Melting Range | 1500°C – 1510°C |

| Modulus of Elasticity | ~200 GPa |

| Thermal Conductivity | Higher than 300-series stainless steels |

| Coefficient of Thermal Expansion | Lower than austenitic grades |

Types of ASTM A815 WP430 Fittings

ASTM A815 WP430 Elbow

ASTM A815 WP430 Tee

ASTM A815 WP430 Reducers

ASTM A815 WP430 Caps

ASTM A815 WP430 Cross Fittings

ASTM A815 WP430 Nipples

ASTM A815 WP430 Couplings

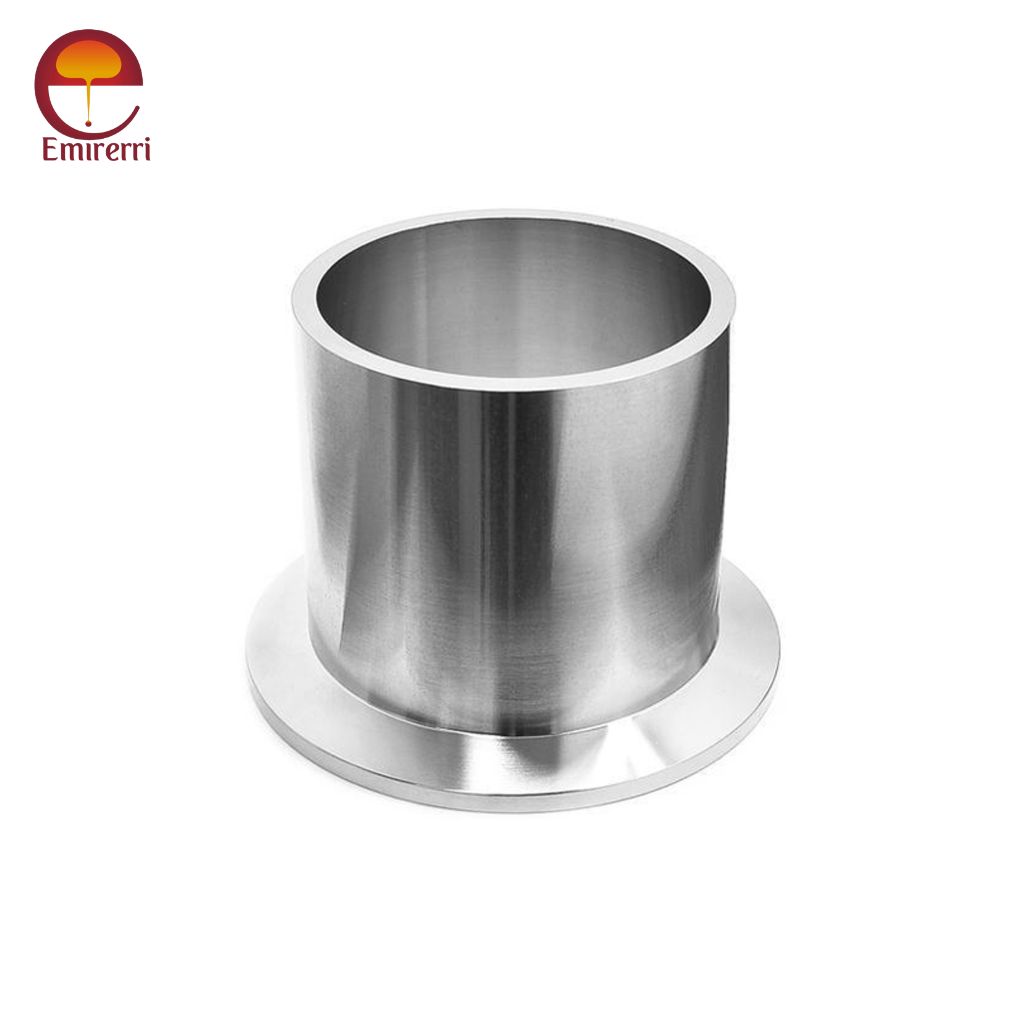

ASTM A815 WP430 Stub Ends

Corrosion Resistance

WP430 provides excellent resistance to:

Atmospheric corrosion

Freshwater & mildly corrosive chemicals

Food processing & mild alkali environments

Organic acids and industrial gases

Not recommended for high-chloride or acidic environments.

Heat Resistance

Good oxidation & scale resistance up to ~815°C

Suitable for exhaust systems, heat exchangers & furnace parts

Low thermal expansion reduces thermal fatigue cracking

Heat Treatment

Annealing: 760°C – 815°C followed by air cooling

Stress-relief recommended after heavy forming

Avoid rapid quenching to minimize brittleness

Welding

Can be welded by standard processes (GTAW, GMAW, SMAW)

Recommended filler metal: matching ferritic grade

Post-weld annealing advised in critical service to restore toughness

Avoid rapid cooling after welding

Fabrication

Good formability & machinability

Can be roll-formed & press-braked

Avoid severe cold-work without annealing

Magnetic — aids in handling & automation

Applications

Chemical processing lines & equipment

Food & beverage industry piping

Architectural handrails & piping systems

Industrial exhaust & furnace components

Heat exchangers & heater elements

Decorative stainless steel systems

Automotive & industrial muffler equipment

Flue gas & chimney systems