ASTM A815 WPS32101

ASTM A815 WPS32101 Duplex Stainless Steel Pipe Fittings

ASTM A815 WPS32101 pipe fittings are manufactured using a duplex stainless steel grade identified by the UNS designation S32101. This grade is known as Lean Duplex Stainless Steel, offering an excellent balance of mechanical strength, corrosion resistance, and cost-efficiency.

These fittings feature a mixed microstructure of ferrite and austenite, providing exceptional yield strength compared to standard austenitic stainless steels like 304/316, while maintaining impressive corrosion resistance in chloride-bearing environments.

Key Features

Lean duplex stainless steel UNS S32101

Higher strength than conventional stainless steel (304/316)

Excellent resistance to pitting & crevice corrosion

Outstanding stress-corrosion cracking resistance

Suitable for seawater, chemicals, and mildly acidic environments

Cost-effective alternative to super duplex grades

Good weldability and fabricability

Specifications

| Standard | ASTM A815 / ASME SA815 |

|---|---|

| Grade | WPS32101 |

| UNS | S32101 |

| Material Type | Lean Duplex Stainless Steel |

| Forms | Butt-weld Pipe Fittings |

| Manufacture | Seamless / Welded / Cold-worked |

| Compliance | ANSI / ASME / MSS-SP-43 / DIN / EN |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | S32101 |

| EN / DIN | 1.4482 |

| ASTM | Lean Duplex Stainless Steel |

| Trade Names | LDX 2101® (Common Industry Name) |

Available Sizes

Butt-weld fittings: ½” to 48”

Schedules: SCH 10 to SCH XXS

Custom dimensions available

Chemical Composition

| Element | % |

|---|---|

| Chromium (Cr) | 21.0 – 22.0 |

| Nickel (Ni) | 1.35 – 1.70 |

| Molybdenum (Mo) | ≤ 0.80 |

| Manganese (Mn) | 4.00 – 6.00 |

| Nitrogen (N) | 0.19 – 0.25 |

| Silicon (Si) | ≤ 1.00 |

| Carbon (C) | ≤ 0.03 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 650 MPa |

| Yield Strength | ≥ 450 MPa |

| Elongation | ≥ 25% |

| Hardness | ≤ 290 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | ~7.7 g/cm³ |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | Higher than Austenitic Grades |

| Melting Range | ~1370 – 1450°C |

Types of ASTM A815 WPS32101 Fittings

ASTM A815 WPS32101 Elbow

ASTM A815 WPS32101 Tee

ASTM A815 WPS32101 Reducers

ASTM A815 WPS32101 Caps

ASTM A815 WPS32101 Cross Fittings

ASTM A815 WPS32101 Nipples

ASTM A815 WPS32101 Couplings

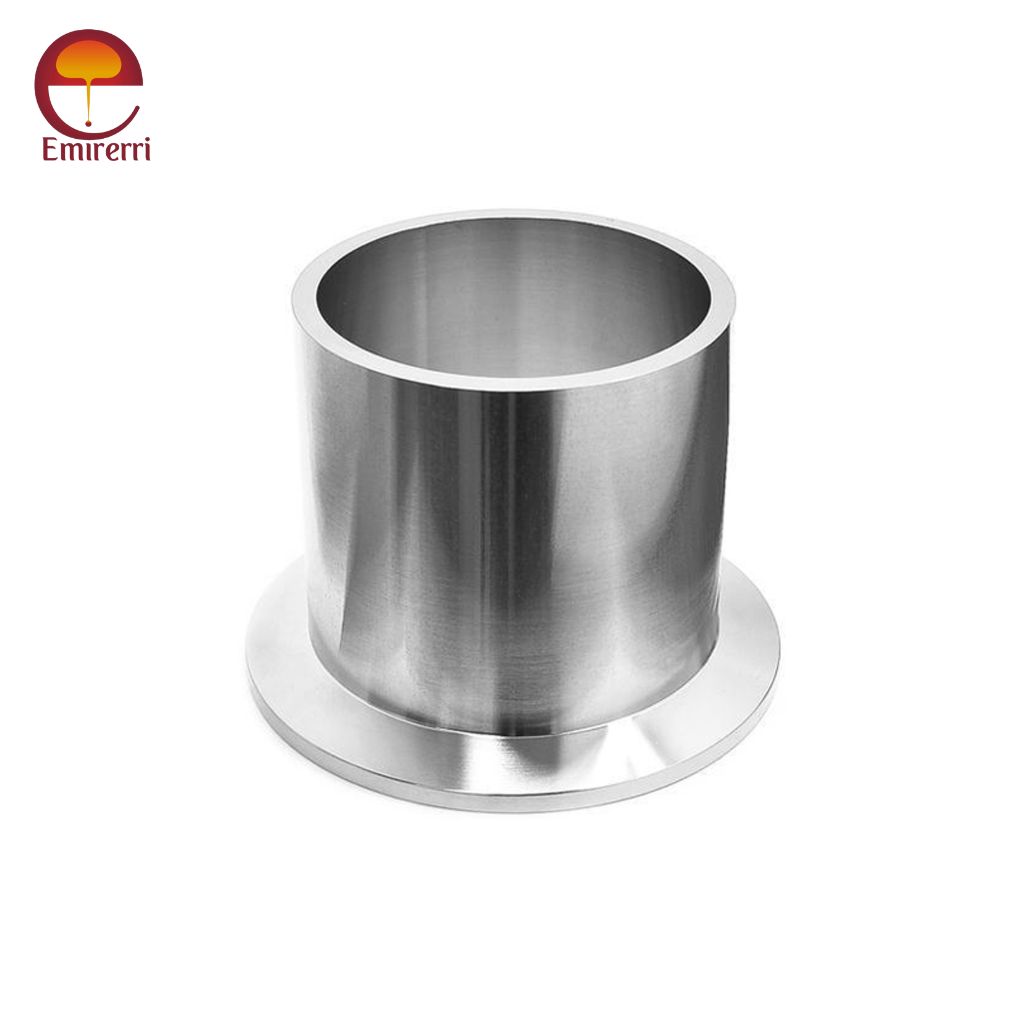

ASTM A815 WPS32101 Stub Ends

Corrosion Resistance

Excellent resistance against:

Chloride-induced pitting and crevice corrosion

Stress-corrosion cracking

Seawater & brackish water

Mild acids & industrial chemicals

Heat Resistance

Suitable for moderate-temperature applications

Avoid prolonged exposure above 300–325°C to prevent embrittlement

Heat Treatment

Solution annealed during production

Cannot be hardened by heat treatment (strength by cold-working)

Welding

Good weldability with duplex-compatible filler metals

Maintain proper heat input for balanced phase structure

Preheat/post-heat generally not required

Fabrication

Good machinability & formability

Use carbide tools for machining

Avoid excessive cold-forming without annealing

Applications

Offshore & Marine Engineering

Chemical & Petrochemical Plants

Desalination Systems & Water Treatment

Power & Energy Industries

Structural Piping Systems

Pulp & Paper Processing

Mining & Mineral Handling