ASTM A815 WPS32202

ASTM A815 WPS32202 Duplex Stainless Steel Pipe Fittings

ASTM A815 WPS32202 pipe fittings are manufactured from Duplex Stainless Steel Grade UNS S32202, a cost-efficient duplex alloy designed to offer excellent mechanical strength, enhanced corrosion resistance, and improved stress-corrosion cracking resistance compared to conventional austenitic stainless steels such as 304/316.

With a balanced ferrite-austenite microstructure, UNS S32202 delivers high tensile strength, lower nickel content for cost efficiency, and reliable performance in chloride-rich and harsh service environments. These fittings are widely used in industrial piping systems where strength, corrosion protection, and long-term durability are critical.

Key Features

Duplex Stainless Steel UNS S32202

Higher strength than 300-series stainless steels

Excellent resistance to pitting & crevice corrosion

Great performance in chloride-containing and marine environments

Strong resistance to stress-corrosion cracking

High fatigue strength & durability

Cost-effective duplex alternative with reduced Ni content

Suitable for high-pressure & corrosive service

Specifications

| Standard | ASTM A815 / ASME SA815 |

|---|---|

| Grade | WPS32202 |

| UNS | S32202 |

| Material Type | Lean Duplex Stainless Steel |

| Form | Butt-Weld Pipe Fittings |

| Manufacturing Process | Seamless / Welded / Cold-Worked |

| Compliance | ASME / ANSI / MSS-SP-43 / EN / DIN |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | S32202 |

| EN / DIN | — (Lean duplex equivalent range) |

| ASTM | Lean Duplex Stainless Steel |

| Trade Names | Commonly marketed as Lean Duplex Alloy |

UNS S32202 is similar in performance category to Duplex UNS S32101 (LDX 2101®), with minor differences in alloy balance.

Available Sizes

Sizes: ½” to 48”

Schedules: SCH 10 – SCH XXS

End Type: Butt-Weld / Beveled / Custom

Custom fittings available on request

Chemical Composition

| Element | % |

|---|---|

| Chromium (Cr) | 21.0 – 23.0 |

| Nickel (Ni) | 0.80 – 2.50 |

| Molybdenum (Mo) | ≤ 0.60 |

| Manganese (Mn) | ≤ 5.00 |

| Nitrogen (N) | 0.15 – 0.35 |

| Silicon (Si) | ≤ 1.00 |

| Carbon (C) | ≤ 0.03 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 650 MPa |

| Yield Strength | ≥ 450 MPa |

| Elongation | ≥ 25% |

| Hardness | ≤ 290 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | ~7.7 g/cm³ |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | Higher than Austenitic SS |

| Melting Range | ~1370 – 1450°C |

Types of ASTM A815 WPS32202 Fittings

ASTM A815 WPS32202 Elbow

ASTM A815 WPS32202 Tee

ASTM A815 WPS32202 Reducers

ASTM A815 WPS32202 Caps

ASTM A815 WPS32202 Cross Fittings

ASTM A815 WPS32202 Nipples

ASTM A815 WPS32202 Couplings

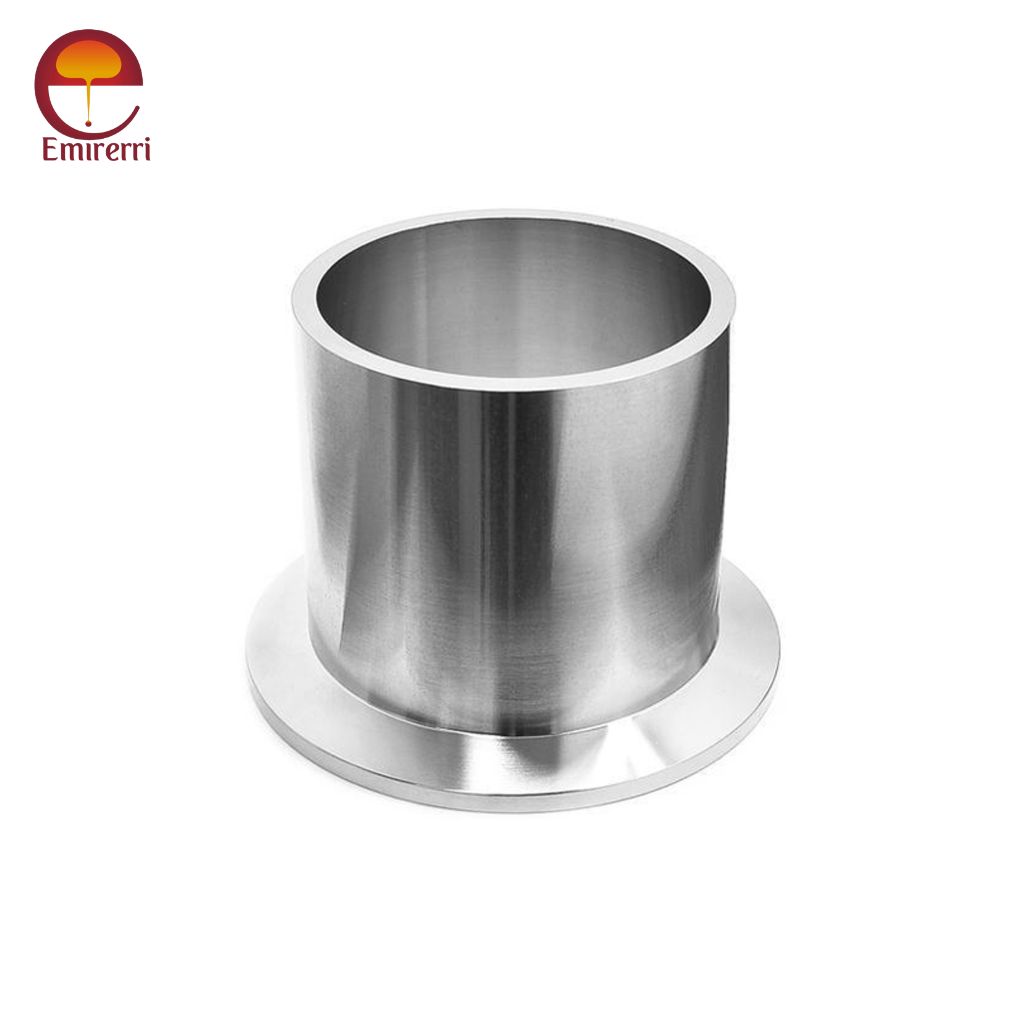

ASTM A815 WPS32202 Stub Ends

Corrosion Resistance

Provides excellent resistance to:

Chloride-induced pitting & crevice corrosion

Stress-corrosion cracking (SCC)

Seawater & brackish water corrosion

Acidic & alkaline industrial environments

Designed to outperform standard stainless grades in corrosive conditions.

Heat Resistance

Suitable for moderate temperature service

Avoid long exposure between 300°C – 600°C to prevent embrittlement

Heat Treatment

Supplied in solution-annealed condition

Cannot be hardened by heat treatment (strength via cold working)

Welding

Good weldability using duplex fillers

Maintain controlled heat input to preserve duplex structure

Pre-heat / Post-weld heat treatment generally not required

Fabrication

Good fabricability with proper tools

Use carbide tooling for machining

Avoid excessive cold forming without intermediate annealing

Applications

Desalination & Water Treatment

Marine & Offshore Applications

Petrochemical & Chemical Processing

Structural Components & Piping Systems

Pulp & Paper Mills

Mining & Mineral Processing

Food & Beverage Processing Equipment