ASTM A815 CRS41008

ASTM A815 CRS41008 Martensitic Stainless Steel Pipe Fittings

ASTM A815 CRS41008 Pipe Fittings are manufactured from ferritic stainless steel grade CRS41008 (UNS S41008), a low-carbon version of Type 410 stainless steel. These fittings are produced under the ASTM A815 standard, which covers wrought ferritic, austenitic, and duplex stainless steel fittings used for high-pressure and corrosive service applications.

The CRS41008 grade offers a balanced combination of strength, ductility, corrosion resistance, and weldability. Its lower carbon content enhances the welding and forming properties while maintaining good mechanical performance and oxidation resistance. ASTM A815 CRS41008 fittings are widely utilized in steam lines, oil & gas systems, thermal power plants, and refinery equipment where reliable performance under elevated temperatures and mild corrosive conditions is essential.

Key Features

Superior weldability and toughness due to low carbon composition.

Excellent resistance to oxidation and scaling up to 650°C.

High tensile and yield strength suitable for pressure applications.

Magnetic and easily machinable in the annealed condition.

Cost-effective alternative to higher alloyed stainless steels.

Suitable for moderate corrosion and temperature conditions.

Specification

| Standard | ASTM A815 / ASME SA815 |

|---|---|

| Grade | CRS41008 |

| UNS Number | S41008 |

| Material Type | Ferritic / Martensitic Stainless Steel |

| Manufacturing Process | Seamless / Welded / Fabricated |

| Size Range | ½” NB to 48” NB |

| Thickness | SCH 10S to SCH 160 / XXS |

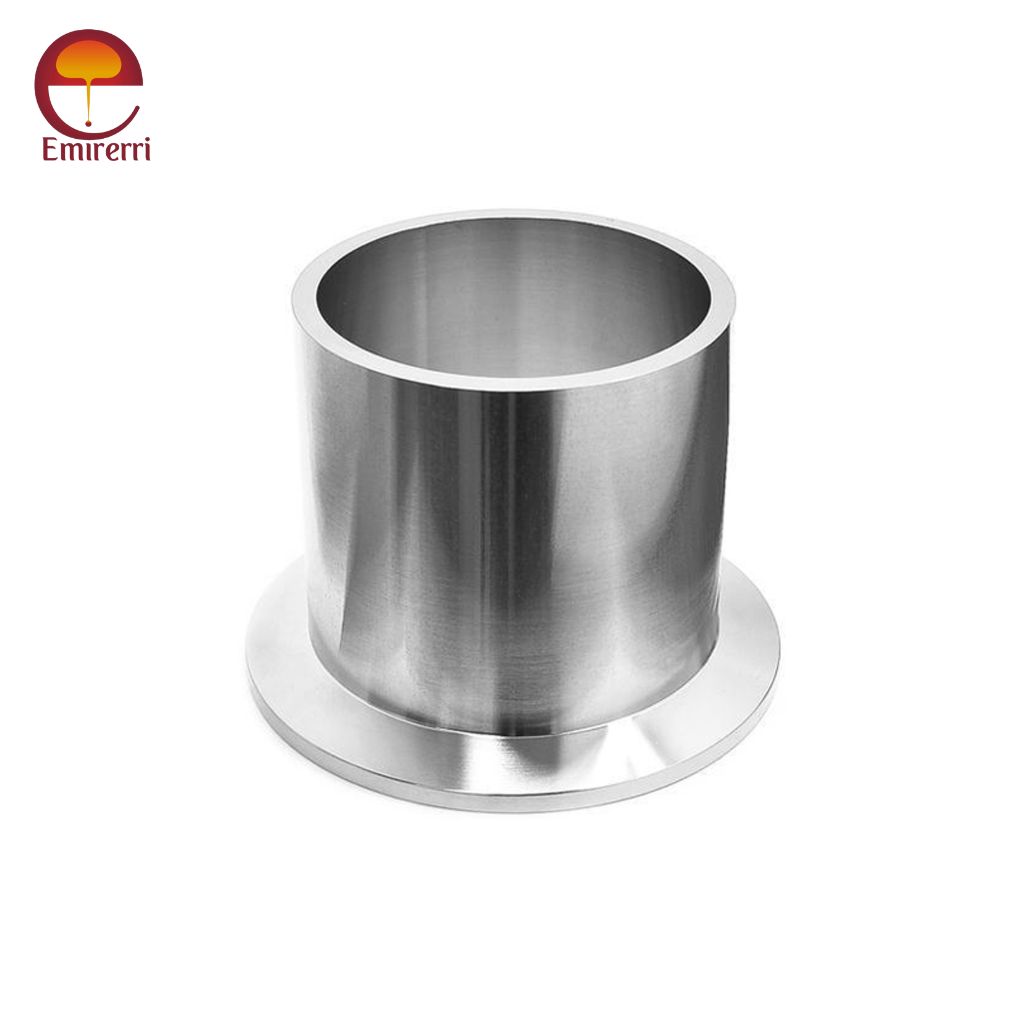

| Form | Elbow, Tee, Reducer, Cap, Stub End, Cross |

| End Type | Beveled / Plain / Custom Ends |

| Testing | NDT, PMI, Hydrostatic, Visual & Dimensional Tests |

Equivalent Grades

| Standard | Equivalent Grade |

|---|---|

| ASTM / ASME | WPS41008 / CRS41008 |

| UNS | S41008 |

| EN | X2Cr12 |

| W.Nr | 1.4000 |

| JIS | SUS410L |

| BS | 410S21 (Modified) |

Available Sizes

Seamless Fittings: ½” NB – 24” NB

Welded Fittings: ½” NB – 48” NB

Wall Thickness: SCH 10S, 40S, 80S, 160, XXS

Custom Sizes: Available on order

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 1.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 11.5 – 13.5 |

| Nickel (Ni) | ≤ 0.75 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 415 – 480 MPa |

| Yield Strength (0.2% Proof) | 240 – 275 MPa |

| Elongation | 20% (min) |

| Hardness (Brinell) | ≤ 217 HB |

| Impact Strength | Improved due to low carbon level |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.75 g/cm³ |

| Melting Point | 1450°C |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 24.9 W/m·K (at 100°C) |

| Electrical Resistivity | 0.57 µΩ·m (at 20°C) |

| Magnetic Properties | Magnetic in all conditions |

Types of ASTM A815 CRS41008 Fittings

ASTM A815 CRS41008 Elbow

ASTM A815 CRS41008 Tee

ASTM A815 CRS41008 Reducers

ASTM A815 CRS41008 Caps

ASTM A815 CRS41008 Cross Fittings

ASTM A815 CRS41008 Nipples

ASTM A815 CRS41008 Couplings

ASTM A815 CRS41008 Stub Ends

Corrosion Resistance

CRS41008 exhibits moderate corrosion resistance in:

Freshwater, mild industrial, and slightly oxidizing environments.

Steam and petroleum processing atmospheres.

Environments where stress corrosion cracking is less of a concern.

However, exposure to acidic and chloride-rich conditions should be avoided to prevent pitting or crevice corrosion.

Heat Resistance

Maintains good oxidation resistance up to 650°C (1200°F).

Withstands intermittent heating and cooling cycles effectively.

Prolonged exposure between 400–600°C should be minimized to prevent embrittlement.

Heat Treatment

Annealing: 815–900°C, followed by air cooling.

Hardening: 925–1010°C, followed by oil or air quenching.

Tempering: 150–370°C depending on the desired hardness and ductility.

Heat treatment improves toughness and reduces brittleness after welding.

Welding

Excellent weldability compared to standard 410 grades.

Suitable welding methods: TIG (GTAW), MIG (GMAW), SMAW, SAW.

Preheat: 150–250°C; Post-weld tempering: 650–750°C.

Recommended filler metals: E410, E410NiMo, or E309 (for dissimilar joints).

Fabrication

Good machinability and formability when annealed.

Cold working is limited due to higher hardness.

Forming operations should be performed at elevated temperatures to prevent cracking.

Post-fabrication heat treatment recommended for dimensional stability.

Applications

Heat Exchangers & Condensers

Power Generation Components

Oil & Gas Refining Equipment

Steam Turbine Parts

Pulp & Paper Industry Components

Pressure Vessels and Valves

Automotive Exhaust and Structural Systems