ASTM A815 WPS41500

ASTM A815 WPS41500 Martensitic Stainless Steel Pipe Fittings

ASTM A815 WPS41500 Pipe Fittings are made from martensitic stainless steel Grade 41500 (UNS S41500), a high-strength, hardenable stainless steel designed for applications requiring both corrosion resistance and superior mechanical properties.

Manufactured under the ASTM A815 / ASME SA815 standard, these fittings are suitable for pressure piping and process applications involving steam, oil, gas, and mildly corrosive fluids. The presence of chromium, molybdenum, and nickel enhances the alloy’s toughness, wear resistance, and weldability, making it ideal for demanding industrial environments.

Key Features

Exceptional mechanical strength and toughness.

Enhanced corrosion and pitting resistance due to Mo addition.

Excellent oxidation and scaling resistance up to 650°C.

Hardenable by heat treatment for improved strength.

Good machinability and dimensional stability.

Balanced weldability and formability.

Specification

| Standard | ASTM A815 / ASME SA815 |

|---|---|

| Grade | WPS41500 |

| Material Type | Martensitic Stainless Steel |

| UNS Number | S41500 |

| W.Nr. | 1.4313 |

| Manufacturing Type | Seamless / Welded / Fabricated |

| Size Range | ½” NB to 48” NB |

| Wall Thickness | SCH 10S to SCH 160 / XXS |

| Form | Elbows, Tees, Reducers, Caps, Stub Ends, Crosses |

| End Connection | Beveled / Plain / Custom Ends |

| Testing | PMI, NDT, Hydrostatic, Visual & Dimensional Tests |

Equivalent Grades

| Standard | Equivalent Grade |

|---|---|

| ASTM / ASME | WPS41500 |

| UNS | S41500 |

| EN | X4CrNiMo16-5-1 |

| W.Nr | 1.4313 |

| JIS | SUS630 (Approx.) |

| BS | 431S29 |

Available Sizes

Seamless Fittings: ½” NB to 24” NB

Welded Fittings: ½” NB to 48” NB

Wall Thickness: SCH 10S, 40S, 80S, 160, XXS

Custom Sizes: Available as per client specifications

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.05 |

| Manganese (Mn) | ≤ 1.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 14.0 – 16.0 |

| Nickel (Ni) | 4.0 – 6.0 |

| Molybdenum (Mo) | 0.4 – 1.0 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 760 – 930 MPa |

| Yield Strength (0.2% Proof) | 550 MPa (min) |

| Elongation | 16% (min) |

| Hardness (Brinell) | ≤ 280 HB |

| Impact Toughness | 35 J (min) at room temperature |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.74 g/cm³ |

| Melting Point | 1440°C |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 24.9 W/m·K (at 100°C) |

| Specific Heat | 460 J/kg·K |

| Magnetic Properties | Magnetic in all conditions |

Types of ASTM A815 WPS41500 Fittings

ASTM A815 WPS41500 Elbow

ASTM A815 WPS41500 Tee

ASTM A815 WPS41500 Reducers

ASTM A815 WPS41500 Caps

ASTM A815 WPS41500 Cross Fittings

ASTM A815 WPS41500 Nipples

ASTM A815 WPS41500 Couplings

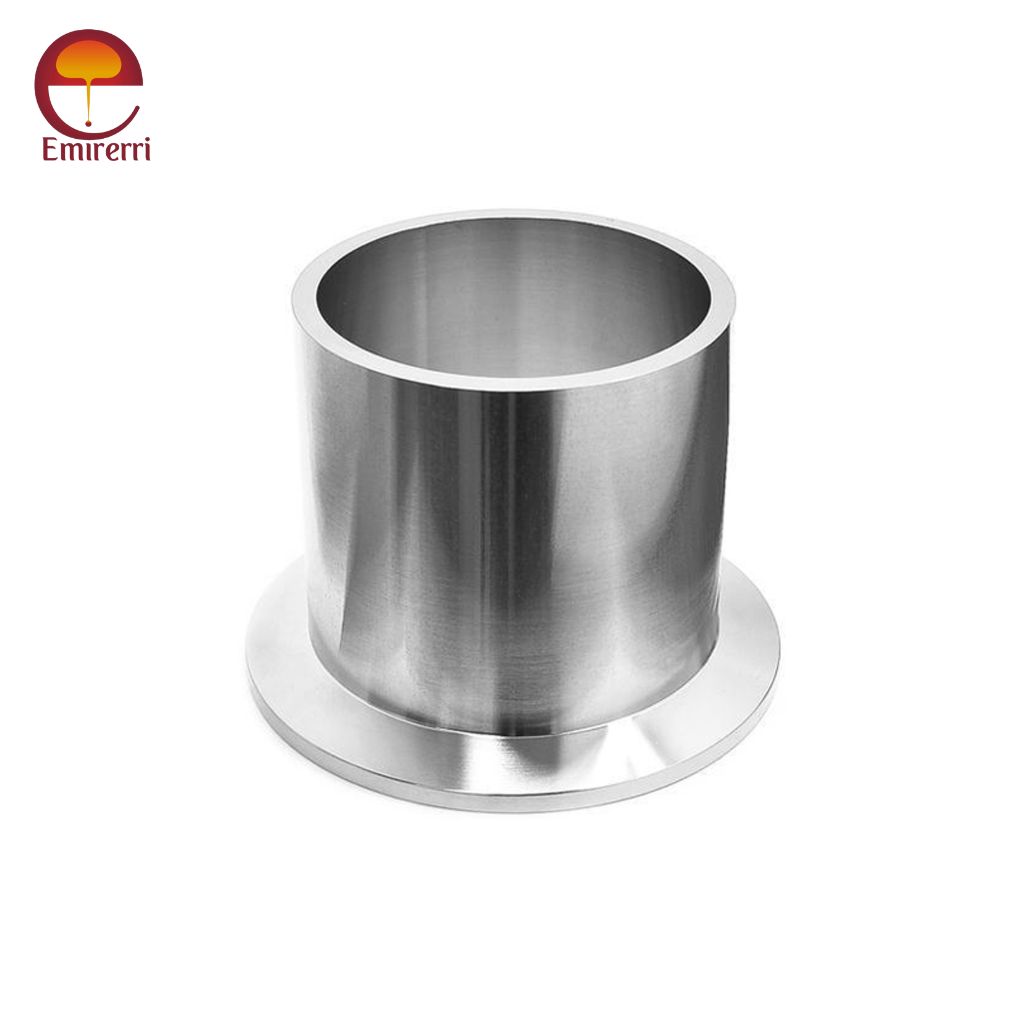

ASTM A815 WPS41500 Stub Ends

Corrosion Resistance

ASTM A815 WPS41500 fittings demonstrate superior corrosion resistance compared to standard 410 grades due to the addition of nickel and molybdenum.

They resist:

Mild acids, alkaline solutions, and freshwater corrosion.

Oxidizing and moderately reducing environments.

Pitting and crevice corrosion in chloride-containing environments.

This makes them ideal for marine, chemical processing, and oilfield applications.

Heat Resistance

Excellent oxidation resistance up to 650°C (1200°F).

Maintains mechanical integrity and surface stability under cyclic thermal exposure.

Not recommended for continuous service in the 400–600°C range due to risk of temper embrittlement.

Heat Treatment

Solution Annealing: 1000–1050°C, air or oil quenched.

Tempering: 400–600°C to achieve desired hardness and toughness.

Heat treatment enhances mechanical strength, ductility, and corrosion resistance.

Welding

Readily weldable using GTAW (TIG), GMAW (MIG), SMAW, and SAW processes.

Preheat: 150–250°C; Post-weld tempering: 650–750°C recommended.

Use E410NiMo or E309 filler metals for best results.

Post-weld heat treatment required to restore corrosion resistance and reduce residual stresses.

Fabrication

Easily machined in the annealed condition.

Can be formed or cold worked with proper tooling.

Stress-relief annealing recommended after heavy forming.

Surface finishing and polishing are easily achieved for process equipment use.

Applications

Pressure Vessels & Steam Turbines

Power Generation and Energy Plants

Oil & Gas Processing Systems

Marine & Offshore Equipment

Heat Exchangers and Condensers

Pump Shafts, Valves & Fittings

Petrochemical Equipment and Pulp Industry