ASTM A182 F12

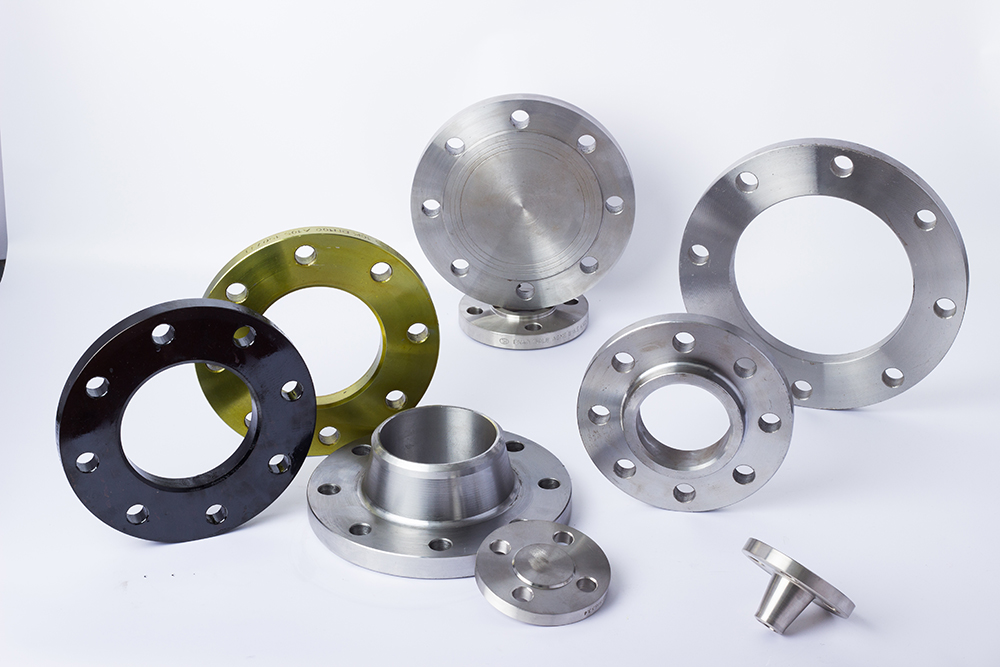

ASTM A182 F12 Alloy Steel Pipe Flanges / Fittings

ASTM A182 F12 is a chromium-molybdenum (Cr-Mo) alloy steel grade used for forged flanges, fittings, valves, and high-temperature components. It is widely chosen for elevated-temperature service, offering better strength, creep resistance, and oxidation resistance compared to carbon steels.

This material is especially suited for refinery piping, steam lines, pressure vessels, and other high-temperature industrial environments.

Key Features

Excellent high-temperature strength and stability

Good creep resistance for long-term service

Improved oxidation and scaling resistance

Suitable for forged components such as flanges & fittings

Good fabrication and weldability with proper heat treatment

Cost-effective compared to stainless steels for similar temperature ranges

Specification

| Specification | Details |

|---|---|

| Standard | ASTM A182 / ASME SA182 |

| Grade | F12 (Class 1 & Class 2) |

| Material Type | Chromium-Molybdenum Alloy Steel |

| UNS Number | K11562 |

| Manufacturing Process | Forged / Rolled |

| Common Forms | Flanges, Forged Fittings, Valves, Rings, Discs |

| Heat Treatment | Annealed / Normalized & Tempered |

| Size Range | ½” to 48″ (Flanges), custom forged sizes available |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | K11562 |

| WNR / EN | 1.7335 |

| DIN | 13CrMo44 / 13CrMo4-5 |

| BS | 620 A/B |

| Other | ASTM A336 F12 (for boiler/rotor forgings) |

Available Sizes

Flanges:

½” to 48″

Pressure Classes: 150#, 300#, 600#, 900#, 1500#, 2500#

Forged Fittings:

½” to 4″ (Socket Weld & Threaded)

Bars & Billets:

Dia: 20 mm to 500 mm

(Custom sizes available as per drawing or forging requirement.)

Chemical Composition

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.05 – 0.20 |

| Manganese (Mn) | 0.30 – 0.60 |

| Silicon (Si) | 0.50 – 1.00 |

| Chromium (Cr) | 1.00 – 1.50 |

| Molybdenum (Mo) | 0.44 – 0.65 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.030 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 380–585 MPa |

| Yield Strength (0.2% Offset) | Min. 205 MPa |

| Elongation | Min. 22% |

| Hardness | Max. 187 HB (Class 1), Max. 223 HB (Class 2) |

Physical Properties

| Property | Value (Typical) |

|---|---|

| Density | 7.85 g/cm³ |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | ~ 42 W/m·K |

| Specific Heat | 460 J/kg·K |

| Melting Range | 1425 – 1460°C |

Types / Forms Available

Weld Neck Flanges

Slip-On Flanges

Blind Flanges

Socket Weld Flanges

Threaded Flanges

Forged Elbows, Tees & Reducers

Valve Bodies & Components

Rings, Discs & Custom-Forged Shapes

Corrosion Resistance

Provides good resistance to oxidation and scaling in high-temperature environments

Not suitable for wet corrosive or chloride-rich environments

Performs well in steam, hot gases, and moderate sulfur environments

Heat Resistance

Designed for high-temperature service up to 500–600°C

Stable mechanical strength in steam lines & pressure piping

Good creep strength ensures long-term durability

Chromium improves oxidation resistance during continuous temperature cycles

Heat Treatment

Annealing: 760–900°C followed by slow cooling

Normalizing & Tempering (Class 2):

Normalize: 900–950°C

Temper: 650–760°C

PWHT may be required after welding based on service conditions

Welding & Fabrication

Can be welded using standard alloy steel welding procedures

Suitable filler metals: ER/F 9Cr-1Mo or equivalent

Preheat recommended (150–300°C depending on thickness)

PWHT required to restore toughness & reduce hardness

Good machinability in the annealed condition

Applications

- Oil & Gas

High-pressure flanges

Forged fittings

Hot hydrocarbon lines

- Power Plants

Steam pipelines

Turbine casing parts

Boiler components

- Petrochemical & Refineries

Reactor lines

Furnace & heater tubes

High-temperature valve parts

Heat exchangers

Pressure vessels

Manifolds & header systems