ASTM A182 F22

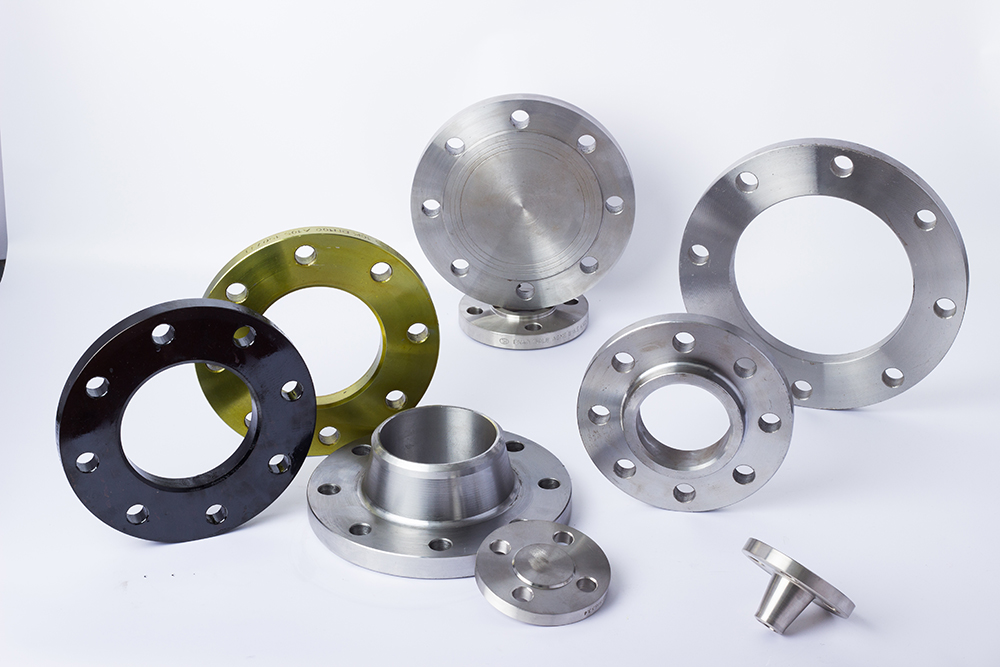

ASTM A182 F22 Alloy Steel Flanges / Fittings

ASTM A182 F22 is a chromium-molybdenum (Cr-Mo) alloy steel grade widely used for high-temperature and high-pressure applications. It offers excellent strength, improved hardenability, superior oxidation resistance, and outstanding performance in elevated temperature environments.

Manufacturers prefer ASTM A182 F22 for forged flanges, fittings, valves, pressure vessels, and power generation components due to its stable metallurgical structure and enhanced mechanical properties.

Key Features

High strength and durability under high pressure

Excellent resistance to oxidation and scaling

Superior performance in elevated temperature services

Good weldability and machinability after heat treatment

Enhanced corrosion resistance in steam, chemical, and petroleum environments

Suitable for power plants, petrochemical units, and boiler equipment

Specification

| Property | Details |

|---|---|

| Grade | ASTM A182 F22 |

| Material | Cr-Mo Alloy Steel |

| Standard | ASTM A182 / ASME SA182 |

| Manufacturing Process | Forged / Rolled / Heat Treated |

| Forms Available | Flanges, Fittings, Rings, Shafts, Bars |

| Class | 150, 300, 600, 900, 1500, 2500 |

| Condition | Annealed / Normalized & Tempered / Quenched & Tempered |

| Size Range | ½” to 48” (Varies by product form) |

Equivalent Grades

| Standard | Grade |

|---|---|

| ASME | SA182 F22 |

| UNS | K21590 |

| DIN | 1.7380 |

| BS | 3603-622-515 |

| EN | 13CrMo4-5 |

Available Sizes

Flanges: ½” to 48”

Forged Fittings: ½” to 4”

Bars & Shafts: 20mm to 450mm diameter

Rings & Custom Forgings: As per drawing

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.05 – 0.15 |

| Manganese (Mn) | 0.30 – 0.60 |

| Silicon (Si) | 0.50 – 1.00 |

| Chromium (Cr) | 2.00 – 2.50 |

| Molybdenum (Mo) | 0.90 – 1.10 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 415 MPa (Min) |

| Yield Strength | 205 MPa (Min) |

| Elongation | 20% (Min) |

| Hardness (HB) | 179 – 217 |

| Impact Strength | Good at room & elevated temperatures |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.80 g/cm³ |

| Melting Point | 1400 – 1450°C |

| Thermal Conductivity | 29 W/m·K |

| Modulus of Elasticity | 190 – 210 GPa |

| Specific Heat | 460 J/kg·K |

Types

1. Forged Flanges

Weld Neck Flange

Blind Flange

Slip-On Flange

Socket Weld Flange

Threaded Flange

Lap Joint Flange

Orifice & Spectacle Blinds

2. Forged Fittings

Elbows (45°/90°)

Tees, Crosses

Couplings

Unions

Caps & Plugs

Nipples

3. Custom Forged Products

Rings

Blocks

Shafts

Bars

Corrosion Resistance

ASTM A182 F22 provides moderate corrosion resistance in:

Steam environments

Hydrogen-rich atmospheres

Mild acidic & alkaline media

High-temperature oxidizing conditions

Sulfidation environments

Heat Resistance

Excellent high-temperature strength up to 600–650°C

Strong resistance to thermal fatigue

Good creep resistance and stress rupture strength

Oxidation-resistant in steam and hot gases

Heat Treatment

Applicable heat treatment methods for F22:

Annealing: 860–910°C, air cooling

Normalizing: 900–940°C

Tempering: 650–760°C

Quenching: Oil or water quench as required

Heat treatment enhances hardness, weldability, and creep strength.

Welding

ASTM A182 F22 can be welded using:

TIG welding

MIG welding

SMAW

SAW

Preheating (150–300°C) and post-weld heat treatment (PWHT at 700–760°C) are recommended to prevent cracking and maintain mechanical properties.

Fabrication

Good forgeability at 1000–1200°C

Machining becomes easier after annealing

Suitable for forging complex shapes

Maintains dimensional stability during fabrication

Applications

Power generation equipment

Boiler and pressure vessels

Petrochemical and refinery units

Heat exchangers & superheater parts

Turbine components

High-pressure steam pipelines

Oil & gas processing units

Chemical industries