ASTM A182 F9

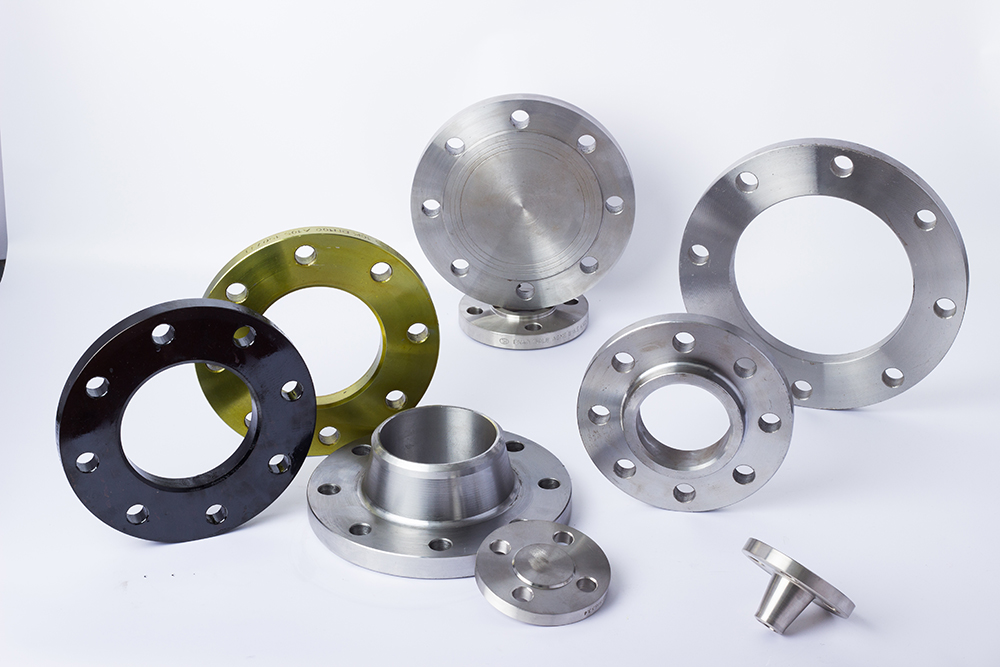

ASTM A182 F9 Alloy Steel Forged Fittings / Flanges

ASTM A182 F9 is a standard specification for forged or rolled alloy steel pipe flanges, fittings, valves, and parts intended for high-temperature and high-pressure applications. This chromium-molybdenum (9Cr-1Mo) alloy steel grade offers exceptional strength, toughness, and resistance to creep and oxidation.

Emirerri Steel manufactures and supplies ASTM A182 F9 Forged Fittings and Flanges designed to deliver superior performance in demanding conditions such as power plants, refineries, chemical industries, and steam systems. Each product is heat-treated, dimensionally accurate, and tested to ensure durability and long service life.

Key Features

Excellent high-temperature and pressure resistance

Superior creep strength and oxidation resistance

High tensile and yield strength

Excellent weldability and machinability

Dimensional precision and consistent performance

Suitable for prolonged exposure to elevated temperatures

Specification

| Specification | Details |

|---|---|

| Standard | ASTM A182 / ASME SA182 |

| Grade | F9 |

| Material | Alloy Steel (9Cr-1Mo) |

| Manufacturing Type | Forged / Rolled / Heat Treated |

| Size Range | ½” NB to 48” NB |

| Pressure Rating | Class 150 to 2500 |

| Form | Elbow, Tee, Cross, Union, Coupling, Plug, Cap, Flange |

| Connection Type | Socket Weld / Threaded / Flanged |

| Dimensions | ASME B16.5, ASME B16.11, MSS SP-79 / SP-95 |

Equivalent Grades

| Standard | Equivalent Grade |

|---|---|

| ASTM | A182 F9 |

| ASME | SA182 F9 |

| UNS | K90941 |

| EN | X12CrMo9-1 |

| DIN | 1.7386 |

| BS | 620B |

Available Sizes

Forged Fittings: ½” NB to 4” NB

Flanges: ½” NB to 48” NB

Pressure Class: 150#, 300#, 600#, 900#, 1500#, 2500#

Thickness: SCH 10S to SCH XXS

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.15 max |

| Manganese (Mn) | 0.30 – 0.60 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

| Silicon (Si) | 0.50 – 1.00 |

| Chromium (Cr) | 8.00 – 10.00 |

| Molybdenum (Mo) | 0.90 – 1.10 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 585 MPa (min) |

| Yield Strength | 380 MPa (min) |

| Elongation | 20% (min) |

| Hardness (Brinell) | ≤ 197 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ |

| Melting Point | 1420–1540°C |

| Thermal Conductivity | 24 W/m·K at 100°C |

| Electrical Resistivity | 0.15 µΩ·m at 20°C |

| Modulus of Elasticity | 205 GPa |

Types of ASTM A182 F9 Products

Forged Fittings: Elbow, Tee, Cross, Union, Coupling, Plug, Cap

Flanges: Weld Neck, Slip-On, Blind, Socket Weld, Threaded, Lap Joint

Outlet Fittings: Weldolet, Sockolet, Threadolet

Custom Forged Components: Valve Parts, Connectors, Rings, Discs

Corrosion Resistance

ASTM A182 F9 alloy steel provides excellent oxidation and scaling resistance in high-temperature environments. The 9% chromium enhances surface protection, while molybdenum improves pitting and hot corrosion resistance. However, for highly acidic or chloride environments, protective coatings or surface treatments are recommended.

Heat Resistance

F9 alloy steel is designed for continuous service in temperatures up to 620°C (1148°F). The combination of chromium and molybdenum provides excellent creep strength, thermal stability, and resistance to thermal fatigue, making it ideal for power and steam systems.

Heat Treatment

Normalizing: 950–1000°C followed by air cooling

Tempering: 720–780°C to improve ductility and toughness

Annealing: 870–920°C to refine grain structure and relieve internal stresses

Welding

ASTM A182 F9 is readily weldable using standard methods such as TIG, MIG, and SMAW. Preheating (200–300°C) and post-weld heat treatment (PWHT) are essential to prevent cracking and maintain structural integrity. Recommended filler materials: ER90S-B9 or E9018-B9 for compatibility.

Fabrication

The F9 alloy steel is easily forged, machined, and fabricated under controlled temperatures. Forging temperature should be maintained between 900°C–1200°C for optimal formability. Post-fabrication heat treatment ensures dimensional stability and mechanical uniformity.

Applications

Power Generation Boilers & Superheaters

Steam and Gas Turbine Components

Oil & Gas Refineries

Petrochemical and Chemical Processing Units

Heat Exchangers and Pressure Vessels

High-Temperature Steam Piping Systems