ASTM A182 F91

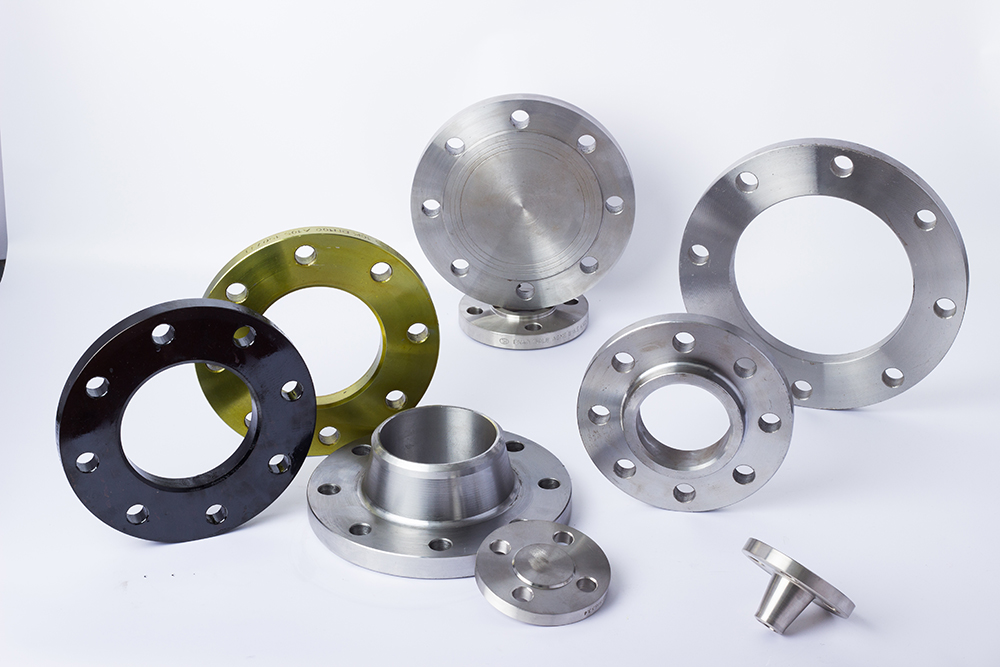

ASTM A182 F91 Alloy Steel Flange / Fittings

ASTM A182 F91 is a high-performance 9% Chromium and 1% Molybdenum (9Cr-1Mo) alloy steel grade designed for high-temperature, high-pressure, and creep-resistant applications. F91 is widely used in power plants, boilers, turbines, and petrochemical units due to its superior strength, oxidation resistance, and long-term stability at elevated temperatures.

The grade undergoes a unique normalizing and tempering (N+T) heat treatment, which enhances creep strength and improves microstructural stability, making it one of the most commonly used materials for ultra-supercritical power generation components.

Key Features

Outstanding high-temperature strength and creep resistance

Excellent thermal stability for long-term service

High chromium content for superior oxidation resistance

Suitable for elevated temperature pressure equipment

Improved weldability with controlled heat treatment

Excellent hardness retention at high temperatures

Better performance compared to other Cr-Mo grades like F11 and F22

Specification

| Property | Details |

|---|---|

| Grade | ASTM A182 F91 |

| UNS | K91560 |

| Material | 9Cr-1Mo-V-Nb Alloy Steel |

| Standard | ASTM A182 / ASME SA182 |

| Classes | 150, 300, 600, 900, 1500, 2500 |

| Manufacturing Process | Forged / Normalized & Tempered |

| Product Forms | Flanges, Fittings, Rings, Shafts, Pipe Spools |

| Size Range | ½” to 48” (depending on product type) |

Equivalent Grades

| Standard | Grade |

|---|---|

| ASME | SA182 F91 |

| UNS | K91560 |

| EN | X10CrMoVNb9-1 |

| DIN | 1.4903 |

| BS | 622-515 / 3604 |

| JIS | SUH 616 |

Available Sizes

Flanges

½” to 48”

Class 150 to 2500

Raised Face, RTJ, Flat Face available

Forged Fittings

½” to 4”

3000#, 6000#, 9000#

Bars / Shafts

20mm to 500mm diameter

Custom Forged Components

Rings, discs, blocks, machined components

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Carbon (C) | 0.08 – 0.12 |

| Manganese (Mn) | 0.30 – 0.60 |

| Silicon (Si) | 0.20 – 0.50 |

| Chromium (Cr) | 8.00 – 9.50 |

| Molybdenum (Mo) | 0.85 – 1.05 |

| Vanadium (V) | 0.18 – 0.25 |

| Niobium (Nb) | 0.06 – 0.10 |

| Nitrogen (N) | 0.03 – 0.07 |

| Phosphorus (P) | ≤ 0.020 |

| Sulfur (S) | ≤ 0.010 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 585 MPa (Min) |

| Yield Strength | 415 MPa (Min) |

| Elongation | 20% (Min) |

| Hardness | 190–250 HB |

| Impact Strength | Excellent at elevated temperatures |

| Creep Strength | Exceptional long-term creep resistance |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.78 g/cm³ |

| Melting Point | 1420–1460°C |

| Thermal Conductivity | 27–31 W/m·K |

| Modulus of Elasticity | 200–215 GPa |

| Specific Heat | 460 J/kg·K |

| Thermal Expansion Coefficient | 11.5 µm/m°C |

Types

1. Forged Flanges

Weld Neck Flange

Slip-On Flange

Blind Flange

Threaded Flange

Lap Joint Flange

Socket Weld Flange

RTJ Flange

Orifice Flange

Spectacle Blinds

2. Forged Fittings

Elbows (45° & 90°)

Equal Tee & Reducing Tee

Cross

Couplings

Caps

Plugs

Unions

Swage Nipples

3. Custom Forgings

Rings

Discs

Forged Bars

Shafts

Blocks

Corrosion Resistance

ASTM A182 F91 offers:

Excellent oxidation resistance due to 9% Cr content

Good corrosion resistance in steam environments

Resistant to sulfidation and crevice corrosion

Stable performance in high-temperature acidic gas atmospheres

Heat Resistance

ASTM A182 F91 is engineered for:

Continuous service up to 650–700°C

High resistance to thermal fatigue

Superior resistance to creep, rupture, and stress corrosion cracking

Excellent performance in high-pressure, high-temperature steam systems

Heat Treatment

Typical heat treatment for F91 includes:

| Process | Temperature |

|---|---|

| Normalizing | 1040–1080°C |

| Tempering | 730–780°C |

| Annealing | Not recommended for final properties |

| PWHT After Welding | 730–780°C |

Heat treatment stabilizes the martensitic structure and improves creep resistance.

Welding

F91 is weldable using:

GTAW (TIG)

GMAW (MIG/MAG)

SMAW

SAW

Welding Guidelines

Preheat: 200–300°C

Interpass Temperature: ≤ 350°C

Mandatory PWHT to relieve residual stress

Low hydrogen electrodes required

Fabrication

Good forgeability at 900–1200°C

Machining requires carbide tools due to hardness

Dimensional stability during high-temperature service

Suitable for forming high-strength pressure components

Applications

Superheater and reheater tubes

Power plant piping & steam lines

High-pressure boiler components

Turbine casings and rotors

Petrochemical furnace parts

Heat exchanger systems

Oil & gas refinery applications

Pressure vessels operating at elevated temperatures