ASTM A403 WP904L

ASTM A403 WP904L Pipe Fittings

ASTM A403 WP904L is a high-alloy austenitic stainless steel grade designed for severe corrosion environments, particularly in sulfuric acid, phosphoric acid, and chloride-rich atmospheres. Known for its low carbon content and high nickel-chromium-molybdenum composition, Grade WP904L delivers exceptional resistance to pitting, stress corrosion cracking, and crevice corrosion.

These fittings are extensively used in chemical industries, seawater systems, pharmaceuticals, and oil & gas processing plants where superior durability and corrosion resistance are required.

Key Features

Excellent resistance to sulfuric, phosphoric & hydrochloric acids

High resistance to pitting & crevice corrosion

Low carbon content prevents carbide precipitation & sensitization

Strong mechanical strength & toughness

Suitable for high-temperature & high-pressure pipe systems

Long service life in aggressive environments

Technical Specification Table

| Specification | Details |

|---|---|

| Standard | ASTM A403 / ASME SA403 |

| Grade | WP904L |

| Material | Stainless Steel 904L |

| Process | Seamless / Welded / Fabricated |

| Schedule | SCH 5S, 10S, 20S, 40S, 80S, 160S, XXS |

| Size Range | ½” to 48” |

| Type | Buttweld Pipe Fittings |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | N08904 |

| WNR | 1.4539 |

| JIS | SUS 904L |

| BS | 904S13 |

Available Sizes

Buttweld Fittings: ½” to 48”

Thickness: SCH 5S to XXS

Formats: LR/SR Elbows, Equal/Reducing Tees, Concentric/Eccentric Reducers, End Caps, Stub Ends, Pipe Bends

Chemical Composition (% max)

| Element | Content |

|---|---|

| C | ≤ 0.020 |

| Mn | ≤ 2.00 |

| Si | ≤ 1.00 |

| P | ≤ 0.045 |

| S | ≤ 0.035 |

| Cr | 19.0 – 23.0 |

| Ni | 23.0 – 28.0 |

| Mo | 4.0 – 5.0 |

| Cu | 1.0 – 2.0 |

| Fe | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 490 MPa |

| Yield Strength | ≥ 220 MPa |

| Elongation | ≥ 35% |

| Hardness | ≤ 90 HRB |

Types of ASTM A403 WP904L Fittings

ASTM A403 WP904L Elbow

ASTM A403 WP904L Tee

ASTM A403 WP904L Reducers

ASTM A403 WP904L Caps

ASTM A403 WP904L Cross Fittings

ASTM A403 WP904L Nipples

ASTM A403 WP904L Couplings

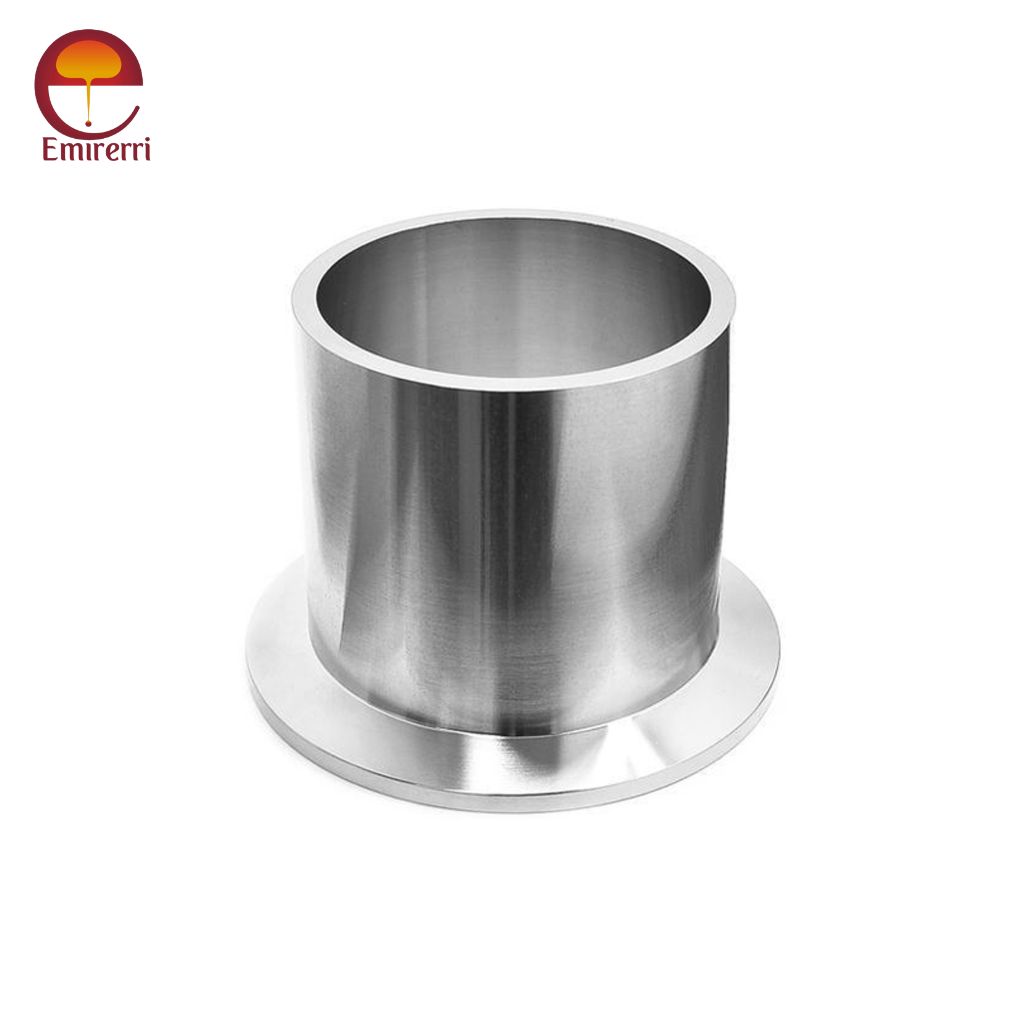

ASTM A403 WP904L Stub Ends

Corrosion Resistance

Excellent in chloride environments

Superior resistance to sulfuric & phosphoric acid

Highly resistant to pitting & crevice corrosion

Ideal for marine & acidic environments

Heat Resistance

Performs well up to 400–450°C

Maintains structural stability and oxidation resistance at high temperature

Heat Treatment

Solution Annealing: 1090°C – 1175°C

Rapid quenching recommended

No post-weld heat treatment required

Weldability

Excellent weldability using TIG/MIG/SAW

Use matching 904L filler metal for maximum corrosion resistance

Low carbon reduces risk of sensitization during welding

Fabrication

Good formability & machinability

Heavy duty cutting tools recommended due to work-hardening tendency

Suitable for deep drawing, bending & forming

Applications

Chemical & Petrochemical Plants

Seawater & Marine Applications

Oil & Gas Refineries

Fertilizer Industry

Pulp & Paper Processing

Pharmaceutical & Food Processing

Heat Exchangers & Pressure Vessels

Desalination Plants

Acid Production Units