ASTM A403 WPS31254 (SMO 254)

ASTM A403 WPS31254 (SMO 254) Pipe Fittings

ASTM A403 WPS31254, commonly known as SMO 254, is a super austenitic stainless steel fitting grade engineered for extreme corrosion resistance in highly aggressive environments. With a balanced composition of high molybdenum (≈6%), nitrogen, and chromium, SMO 254 offers outstanding resistance to pitting, crevice corrosion, and chloride stress-corrosion cracking.

These fittings are widely used in seawater systems, desalination plants, chemical processing, offshore equipment, and flue-gas cleaning systems, making them an ideal solution for industries requiring high strength and longevity in harsh corrosion environments.

Key Features

Extremely high pitting & crevice corrosion resistance

Superior chloride stress-corrosion cracking resistance

High strength & toughness compared to conventional stainless steel

Excellent mechanical properties at both high & low temperatures

Designed for marine, chemical & offshore applications

Excellent weldability & formability

Technical Specification Table

| Specification | Details |

|---|---|

| Standard | ASTM A403 / ASME SA403 |

| Grade | WPS31254 (SMO 254) |

| UNS | S31254 |

| WNR | 1.4547 |

| Form | Seamless / Welded / Fabricated |

| Size Range | ½” to 48” |

| Schedule | SCH 5S to XXS |

| Pressure Class | 150# to 2500# |

| Standards | ANSI / ASME / MSS-SP / DIN |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | S31254 |

| Werkstoff Nr. | 1.4547 |

| EN | X1CrNiMoCuN20-18-7 |

| ASTM | A182 F44 / A240 254SMO |

| Trade Name | 254 SMO |

Available Sizes

Diameter: ½” NB to 48” NB

Thickness: SCH 5S, 10S, 40S, 80S, 160, XXS

Custom sizes & fabricated fittings available on request

Chemical Composition

| Element | Content (%) |

|---|---|

| C | ≤ 0.020 |

| Mn | ≤ 1.00 |

| Si | ≤ 0.80 |

| P | ≤ 0.030 |

| S | ≤ 0.010 |

| Cr | 19.5 – 20.5 |

| Ni | 17.5 – 18.5 |

| Mo | 6.0 – 6.5 |

| Cu | 0.5 – 1.0 |

| N | 0.18 – 0.22 |

| Fe | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 650 MPa |

| Yield Strength | ≥ 300 MPa |

| Elongation | ≥ 35% |

| Hardness | ≤ 96 HRB |

Physical Properties

| Property | Value |

|---|---|

| Density | 8.0 g/cm³ |

| Melting Range | 1320 – 1390°C |

| Thermal Conductivity | 12 W/m-K |

| Electrical Resistivity | 0.90 μΩ-m |

| Modulus of Elasticity | 195 GPa |

Types of ASTM A403 WPS31254 Fittings

ASTM A403 WPS31254 Elbow

ASTM A403 WPS31254 Tee

ASTM A403 WPS31254 Reducers

ASTM A403 WPS31254 Caps

ASTM A403 WPS31254 Cross Fittings

ASTM A403 WPS31254 Nipples

ASTM A403 WPS31254 Couplings

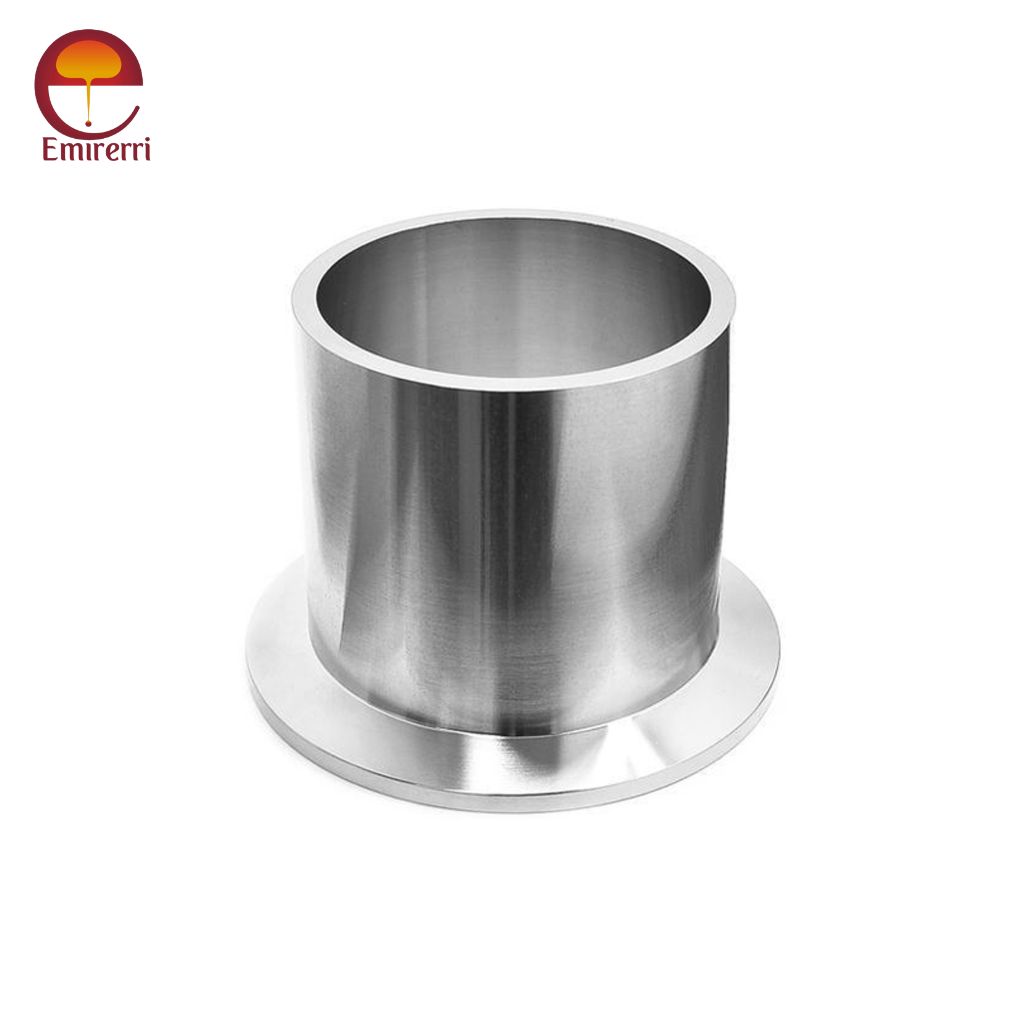

ASTM A403 WPS31254 Stub Ends

Corrosion Resistance

Exceptional performance in seawater & marine environments

Resistant to chloride-induced corrosion

Excellent resistance against pitting & crevice corrosion

Suitable for acidic & saline conditions

Heat Resistance

Stable mechanical properties at elevated temperatures

Recommended continuous service up to 600°C

Good oxidation resistance in moist & dry environments

Heat Treatment

Solution Annealing: 1150 – 1200°C

Rapid cooling / water quenching recommended

No post-weld heat treatment typically required

Welding

Excellent weldability using TIG / MIG / SMAW

Recommended Filler Material: AWS A5.14 ERNiCrMo-3 / ERNiCrMo-7

Avoid slow cooling to prevent intermetallic phase formation

Fabrication

Good formability & machinability

Work hardens rapidly — use rigid tooling

Suitable for bending, forming & deep-drawing

Applications

Desalination Plants & Seawater Handling Systems

Offshore Oil & Gas Platforms

Chemical & Petrochemical Industries

Heat Exchangers & Pressure Vessels

Pulp & Paper Bleaching Plants

Flue-Gas Desulfurization Systems

Marine Engineering & Shipbuilding

Pharmaceutical & Food Industry Equipment