ASTM A815 CR430

ASTM A815 CR430 Stainless Steel Pipe Fittings

ASTM A815 CR430 pipe fittings are manufactured from ferritic stainless steel Grade 430 (UNS S43000) and are designed to deliver dependable performance in moderately corrosive industrial environments. As part of the CR class under ASTM A815/A815M, these fittings are produced in accordance with MSS SP-43 standards, ensuring high-quality construction suitable for lower-pressure and light-duty applications. Known for their excellent resistance to stress corrosion cracking, good formability, and impressive durability at elevated temperatures,

ASTM A815 CR430 fittings are widely used in industries such as chemical processing, food and beverage, heat exchangers, and architectural piping systems. With superior performance in oxidizing conditions and cost-effective production, CR430 stainless steel fittings serve as a reliable and economical solution for process piping systems.

Key Features

Produced using ferritic stainless steel Grade 430 (UNS S43000)

Conforms to ASTM A815 / MSS SP-43 standards

Excellent resistance to mild corrosion and industrial atmospheres

Good oxidation and scaling resistance up to elevated temperatures

Superior resistance to stress-corrosion cracking vs austenitic steels

Good formability, weldability, and dimensional stability

Magnetic stainless steel with low thermal expansion

Specification

| Property | Details |

|---|---|

| Standard | ASTM A815 / A815M |

| Class | CR (MSS SP-43) |

| Grade | CR430 |

| Material Type | Ferritic Stainless Steel |

| UNS Designation | S43000 |

| AISI Equivalent | 430 |

| Manufacturing | Welded / Seamless |

| Sizes | ½” – 48” (DN15–DN1200) |

| Thickness | SCH 10 – SCH XXS |

| End Form | Bevelled Ends (BW) |

| Surface Finish | Mill Finish / Pickled & Passivated |

Equivalent Grades

| Standard | Grade |

|---|---|

| ASTM | A815 CR430 |

| UNS | S43000 |

| AISI | 430 |

| EN | 1.4016 |

| JIS | SUS 430 |

Available Sizes

Pipe Size: ½” to 48”

Wall Thickness: SCH 10 – XXS

Available Dimensions: ANSI/ASME B16.9 & B16.28

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 16.0 – 18.0 |

| Carbon (C) | ≤ 0.12 |

| Manganese (Mn) | ≤ 1.00 |

| Silicon (Si) | ≤ 1.00 |

| Nickel (Ni) | ≤ 0.50 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 450 MPa |

| Yield Strength | ≥ 280 MPa |

| Elongation | ≥ 20% |

| Hardness | ≤ 202 HBW |

Physical Properties

| Property | Value |

|---|---|

| Density | ~7.7 g/cm³ |

| Melting Range | 1500–1510°C |

| Modulus of Elasticity | ~200 GPa |

| Thermal Conductivity | Higher vs austenitic stainless |

| Thermal Expansion | Lower vs 304/316 stainless |

Types of ASTM A815 CR430 Fittings

ASTM A815 CR430 Elbow

ASTM A815 CR430 Tee

ASTM A815 CR430 Reducers

ASTM A815 CR430 Caps

ASTM A815 CR430 Cross Fittings

ASTM A815 CR430 Nipples

ASTM A815 CR430 Couplings

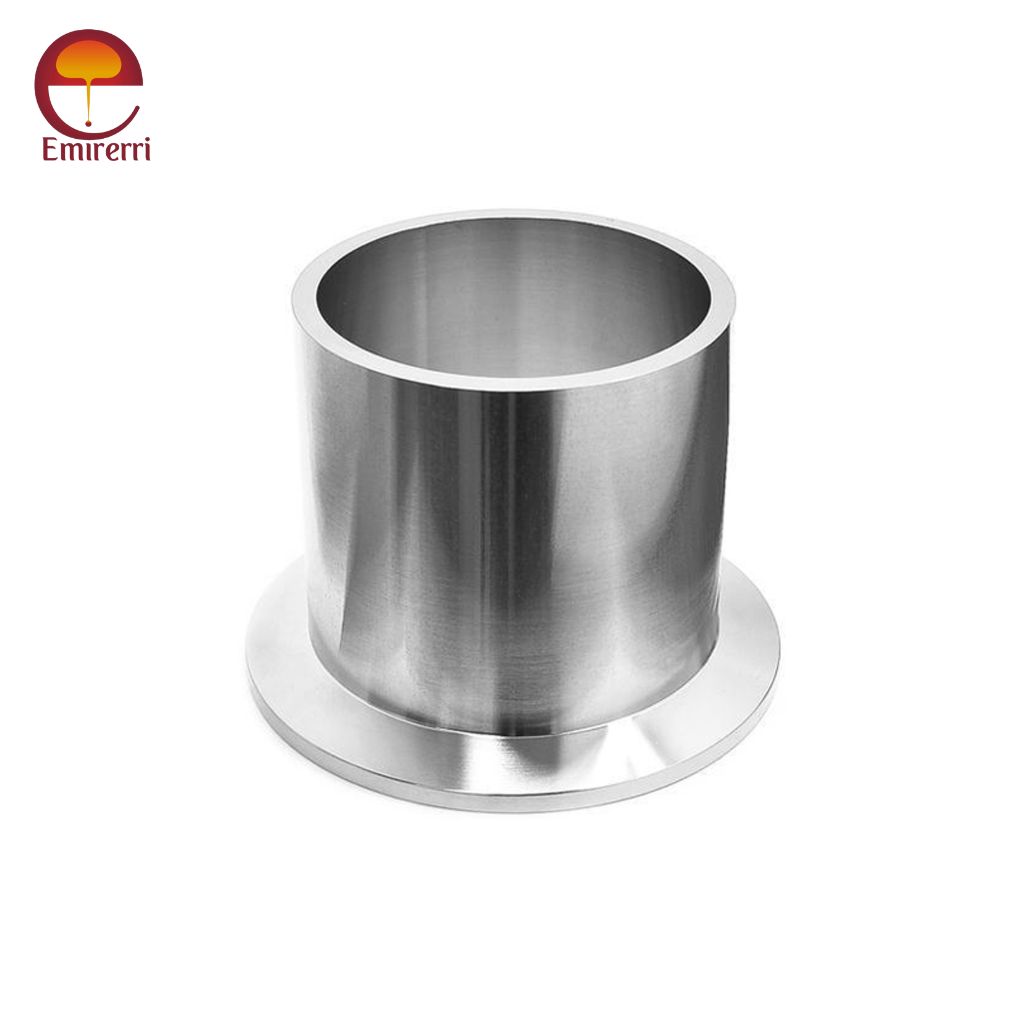

ASTM A815 CR430 Stub Ends

Corrosion Resistance

Suitable for mild chemical, alkaline & atmospheric environments

Good resistance to water, organic acids & food-processing media

Strong resistance to stress corrosion cracking

Not recommended for high chloride or acidic service

Heat Resistance

Good oxidation resistance up to ~815°C

Resists thermal scaling at high temperature

Ideal for exhaust systems, furnaces & heat exchangers

Heat Treatment

Annealing: 760°C – 815°C, air cool

Stress relief advisable after severe forming

Avoid rapid water quenching — may cause brittleness

Welding

Weldable using standard stainless welding methods

Recommended filler metals: ferritic or matching 430 grade

Post-weld annealing recommended in demanding applications

Pre-heat typically not required

Fabrication

Good machinability & press-forming ability

Can be roll-formed and bent

Magnetic and easy to process in fabrication lines

Avoid excessive cold work without annealing

Applications

Chemical processing systems

Food processing & dairy equipment

Architectural & interior piping systems

Exhaust & flue gas systems

Heat exchangers & industrial furnaces

Decorative stainless installations

Water treatment piping

Automotive exhaust components