ASTM A815 CR446

ASTM A815 CR446 Ferritic Stainless Steel Pipe Fittings

ASTM A815 CR446 pipe fittings are manufactured from high-chromium ferritic stainless steel Grade 446 (commonly aligned with UNS S44600 or similar high-Cr alloys) under the CR class, meaning they are cold-worked welded stainless steel fittings manufactured to the MSS SP-43 standard. These fittings are designed for excellent resistance to high-temperature oxidation, sulfidation, and severe corrosion in industrial environments.

With chromium content up to ~27%, CR446 fittings offer superior performance in elevated temperature and aggressive chemical service, making them ideal for furnace systems, heat-exchanger plants, flue gas handling, and petrochemical processing units. Their high structural stability and thermal strength ensure reliable operation in heat-intensive and corrosive service conditions.

Key Features

High-chromium ferritic stainless steel

Manufactured to CR Class (MSS SP-43)

Exceptional high-temperature oxidation and scaling resistance

Superior sulfidation resistance in combustion & gas environments

Excellent chloride stress corrosion cracking resistance

Stable microstructure in elevated temperature applications

Reliable mechanical performance in aggressive chemical service

Specifications

| Specification | Details |

|---|---|

| Standard | ASTM A815 / A815M |

| Grade / Class | CR446 |

| UNS Designation | S44600 / (or equivalent high-Cr ferritic grade) |

| Manufacturing Class | CR – Cold-worked welded fittings per MSS SP-43 |

| Material Type | Ferritic stainless steel |

| Form | Butt-weld pipe fittings |

| Standards | MSS SP-43 / ASME B16.9 / B16.28 (as applicable) |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | S44600 (commonly used) |

| AISI | 446 |

| EN | 1.4762 / 1.4763 (approx.) |

| JIS | SUS 446 |

Available Sizes

NPS: ½” to 24”

Schedules: SCH 10S to SCH 80

Availability: Welded cold-worked fittings

Chemical Composition

| Element | % |

|---|---|

| Chromium (Cr) | 23.0 – 27.0 |

| Carbon (C) | ≤ 0.20 |

| Manganese (Mn) | ≤ 1.50 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 485 MPa |

| Yield Strength | ≥ 275 MPa |

| Elongation | ≥ 20% |

Physical Properties

| Property | Value |

|---|---|

| Density | ~7.70 g/cm³ |

| Melting Point | Approx. 1500°C |

| Modulus of Elasticity | ~200 GPa |

| Thermal Conductivity | Higher than austenitic stainless steels |

Types of ASTM A815 CR446 Fittings

ASTM A815 CR446 Elbow

ASTM A815 CR446 Tee

ASTM A815 CR446 Reducers

ASTM A815 CR446 Caps

ASTM A815 CR446 Cross Fittings

ASTM A815 CR446 Nipples

ASTM A815 CR446 Couplings

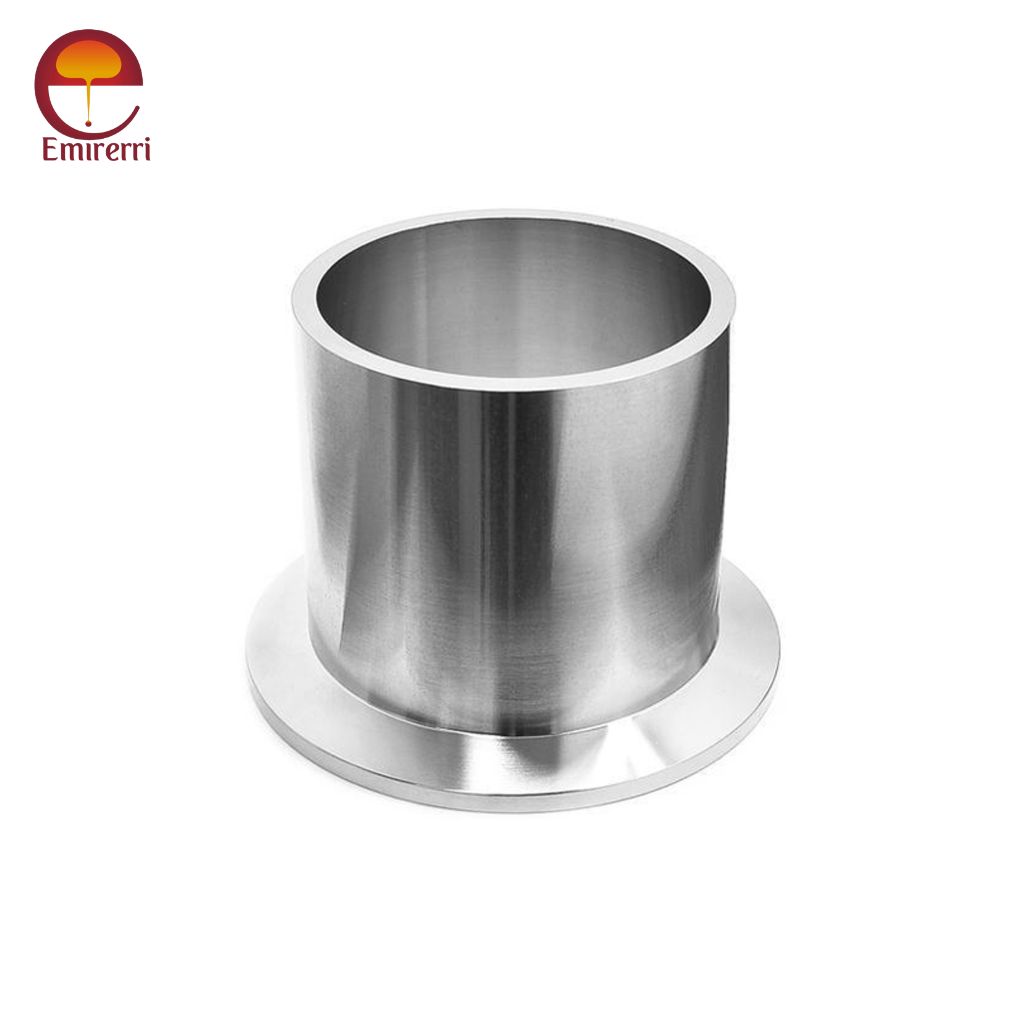

ASTM A815 CR446 Stub Ends

Corrosion Resistance

Excellent resistance to:

High-temperature oxidation & scaling

Sulfur-containing gases and combustion atmospheres

Industrial chemical exposure

Chlorides (stress corrosion cracking resistance)

Performance remains stable under thermal cycling & corrosive gas streams.

Heat Resistance

Reliable service in temperatures up to ~1100°C

Outstanding resistance to:

Thermal shock

Carburization & sulfidation

High-temperature oxidation

Heat Treatment

| Process | Description |

|---|---|

| Annealing | 800°C – 900°C, air cool |

| Hardening | Not hardenable by heat treatment |

| Stress Relief | Recommended after heavy cold-work |

Welding

Weldability: Moderate

Suggested welding processes: TIG / MIG / SMAW

Preheat & post-weld heat treatment advisable

Ferritic stainless steel filler recommended

Proper heat control is essential to avoid grain growth.

Fabrication

Good machinability with correct tooling

Suitable for forming & moderate cold-work

Avoid excessive hot-working without controlled heat treatment

Applications

Furnace & thermal processing equipment

Heat exchangers & superheaters

Petrochemical & refinery components

Flue gas & exhaust systems

Industrial kilns & burners

Power plant boiler systems

Metallurgical and combustion environments