ASTM A815 CRS41008

ASTM A815 CRS41500 Martensitic Stainless Steel Pipe Fittings

ASTM A815 CRS41500 Pipe Fittings are manufactured from martensitic stainless steel grade 41500 (UNS S41500), known for its exceptional strength, toughness, and corrosion resistance. This grade is a modification of the 410 family, enriched with nickel and molybdenum, offering superior resistance to pitting, scaling, and oxidation.

Produced in accordance with ASTM A815 / ASME SA815, these fittings are designed for high-pressure and high-temperature service in industries such as power generation, oil & gas, chemical processing, and marine systems. The “CRS” designation highlights the corrosion-resistant stainless nature of the alloy, optimized for both mechanical performance and durability in harsh environments.

Key Features

Excellent corrosion and pitting resistance due to Mo and Ni addition.

High tensile and yield strength suitable for heavy-duty pressure applications.

Good oxidation and scaling resistance up to 650°C.

Magnetic and machinable in annealed condition.

Improved weldability and formability compared to 410 and 420 grades.

Suitable for both moderate and elevated temperature service.

Specification

| Standard | ASTM A815 / ASME SA815 |

|---|---|

| Grade | CRS41500 |

| Material Type | Martensitic Stainless Steel |

| UNS Number | S41500 |

| W.Nr. | 1.4313 |

| Manufacturing Process | Seamless / Welded / Fabricated |

| Size Range | ½” NB to 48” NB |

| Wall Thickness | SCH 10S to SCH 160 / XXS |

| Form | Elbows, Tees, Reducers, Caps, Stub Ends, Crosses |

| End Connections | Beveled, Plain, or Custom Ends |

| Testing | NDT, PMI, Hydrostatic & Visual Inspections |

Equivalent Grades

| Standard | Equivalent Grade |

|---|---|

| ASTM / ASME | WPS41500 / CRS41500 |

| UNS | S41500 |

| EN | X4CrNiMo16-5-1 |

| W.Nr | 1.4313 |

| JIS | SUS630 (Approx.) |

| BS | 431S29 |

Available Sizes

Seamless Fittings: ½” NB – 24” NB

Welded Fittings: ½” NB – 48” NB

Wall Thickness: SCH 10S, 40S, 80S, 160, XXS

Custom Dimensions: Available upon request

Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.05 |

| Manganese (Mn) | ≤ 1.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 14.0 – 16.0 |

| Nickel (Ni) | 4.0 – 6.0 |

| Molybdenum (Mo) | 0.4 – 1.0 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 760 – 930 MPa |

| Yield Strength (0.2% Proof) | 550 MPa (min) |

| Elongation | 16% (min) |

| Hardness (Brinell) | ≤ 280 HB |

| Impact Strength | ≥ 35 J (at room temperature) |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.74 g/cm³ |

| Melting Point | 1440°C |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 24.9 W/m·K (at 100°C) |

| Specific Heat | 460 J/kg·K |

| Magnetic Properties | Fully Magnetic |

Types of ASTM A815 CRS41500 Fittings

ASTM A815 CRS41500 Elbow

ASTM A815 CRS41500 Tee

ASTM A815 CRS41500 Reducers

ASTM A815 CRS41500 Caps

ASTM A815 CRS41500 Cross Fittings

ASTM A815 CRS41500 Nipples

ASTM A815 CRS41500 Couplings

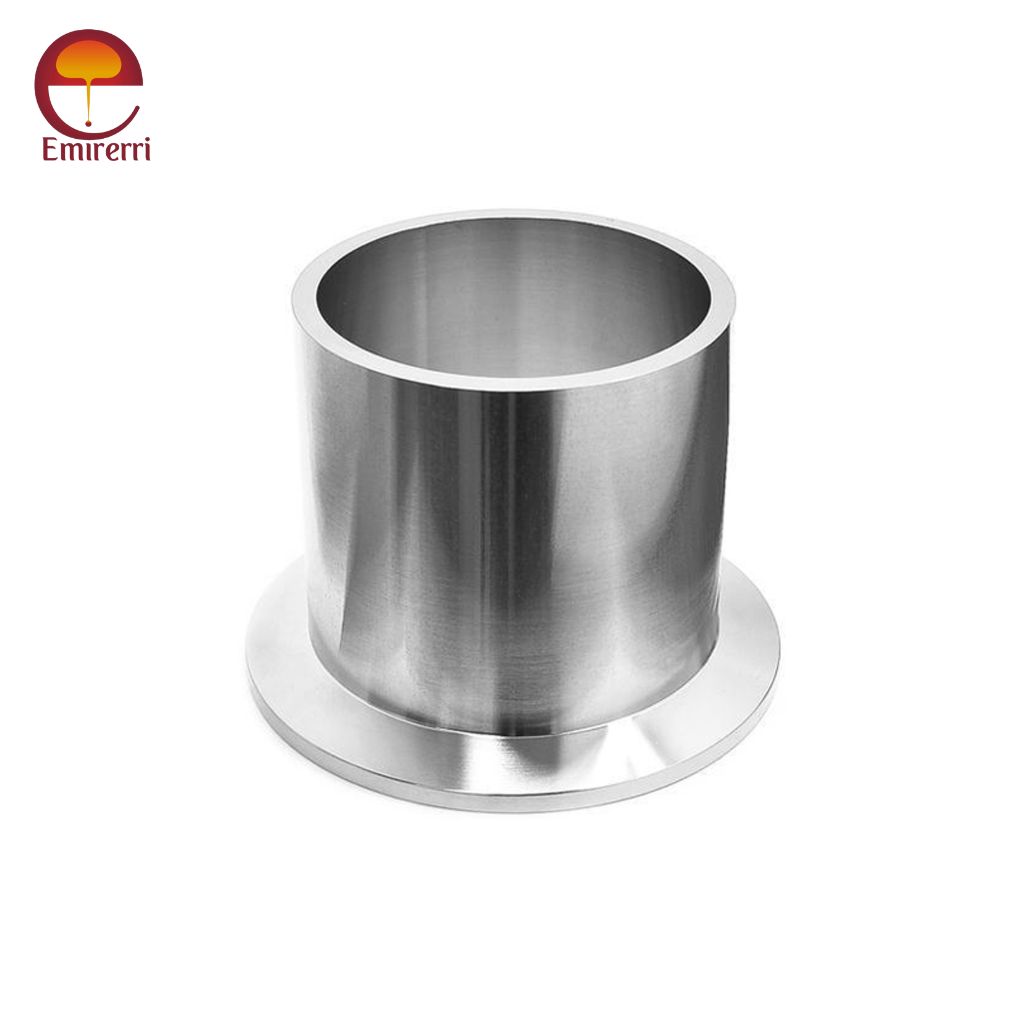

ASTM A815 CRS41500 Stub Ends

Corrosion Resistance

The CRS41500 grade offers superior resistance to:

Mild acids, freshwater, and atmospheric corrosion.

Oxidizing environments and steam exposure.

Pitting and crevice corrosion in chloride environments.

This makes it ideal for marine, refinery, and desalination plant applications. The molybdenum and nickel content significantly enhance its performance over standard 410 grades.

Heat Resistance

Retains mechanical integrity and scaling resistance up to 650°C (1200°F).

Withstands cyclic heating and cooling without loss of strength.

Avoid prolonged exposure between 400–600°C to prevent embrittlement.

Heat Treatment

Solution Annealing: 1000–1050°C, air or oil quenched.

Tempering: 400–600°C to achieve desired balance of hardness and ductility.

Heat treatment restores corrosion resistance and removes welding stresses.

Welding

Readily weldable using TIG (GTAW), MIG (GMAW), SMAW, and SAW processes.

Preheat: 150–250°C | Post-weld tempering: 650–750°C recommended.

Filler Metals: E410NiMo or E309 (for dissimilar joints).

Post-weld heat treatment enhances toughness and reduces stress cracking risk.

Fabrication

Good machinability and formability in the annealed state.

Can be cold-formed with minimal spring-back.

Stress-relief annealing recommended after heavy forming.

Surface finishing and polishing achievable for high-specification process systems.

Applications

Oil & Gas Processing Plants

Power Generation Systems

Heat Exchangers & Condensers

Steam Turbines & Pressure Vessels

Marine & Offshore Components

Pump Shafts, Valves & Fasteners

Petrochemical & Pulp Industry Equipment