ASTM A815 WP27

ASTM A815 WP27 Stainless Steel Fittings

ASTM A815 WP27 is a high-performance wrought ferritic stainless steel alloy designed for demanding industrial applications, especially where corrosion resistance and heat resistance are essential. It offers excellent mechanical properties, weldability, and compatibility with various fabrication processes, making it ideal for piping and fitting assemblies in harsh environments.

Key Features:

High corrosion and oxidation resistance

Excellent weldability and formability

Suitable for high-temperature applications

Meets strict industry standards

Technical Specification

| Specification | Details |

|---|---|

| Standard | ASTM A815 / ASME SA815 |

| Grade | WP27 Duplex Stainless Steel |

| Product Type | Seamless / Welded / Fabricated Fittings |

| Size Range | ½” to 48” |

| Thickness | SCH 5S to XXS |

| Pressure Rating | Class 150 to 2500 |

| Forms | Buttweld Pipe Fittings |

Equivalent Grades

| Standard | Equivalent Grade |

|---|---|

| UNS | S32750 / S32760 (Depending on variant)* |

| WNR | 1.4410 / 1.4501 |

| EN | X2CrNiMoN25-7-4 / X2CrNiMoCuWN25-7-4 |

| Trade Names | Super Duplex / Duplex 27Cr Series |

Chemical Composition (Typical)

| Element | Content (%) |

|---|---|

| C | ≤ 0.03 |

| Mn | ≤ 2.00 |

| Si | ≤ 1.00 |

| P | ≤ 0.035 |

| S | ≤ 0.020 |

| Cr | 24 – 27 |

| Ni | 6 – 8 |

| Mo | 3 – 4 |

| N | 0.20 – 0.30 |

| Fe | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 750 MPa |

| Yield Strength | ≥ 550 MPa |

| Elongation | ≥ 25% |

| Hardness | ≤ 32 HRC |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.8 g/cm³ |

| Melting Point | ~1350°C |

| Thermal Conductivity | 14 W/m-K |

| Electrical Resistivity | 0.85 µΩ-m |

| Modulus of Elasticity | 200 GPa |

Types of ASTM A815 WP27 Fittings

ASTM A815 WP27 Elbow

ASTM A815 WP27 Tee

ASTM A815 WP27 Reducers

ASTM A815 WP27 Caps

ASTM A815 WP27 Cross Fittings

ASTM A815 WP27 Nipples

ASTM A815 WP27 Couplings

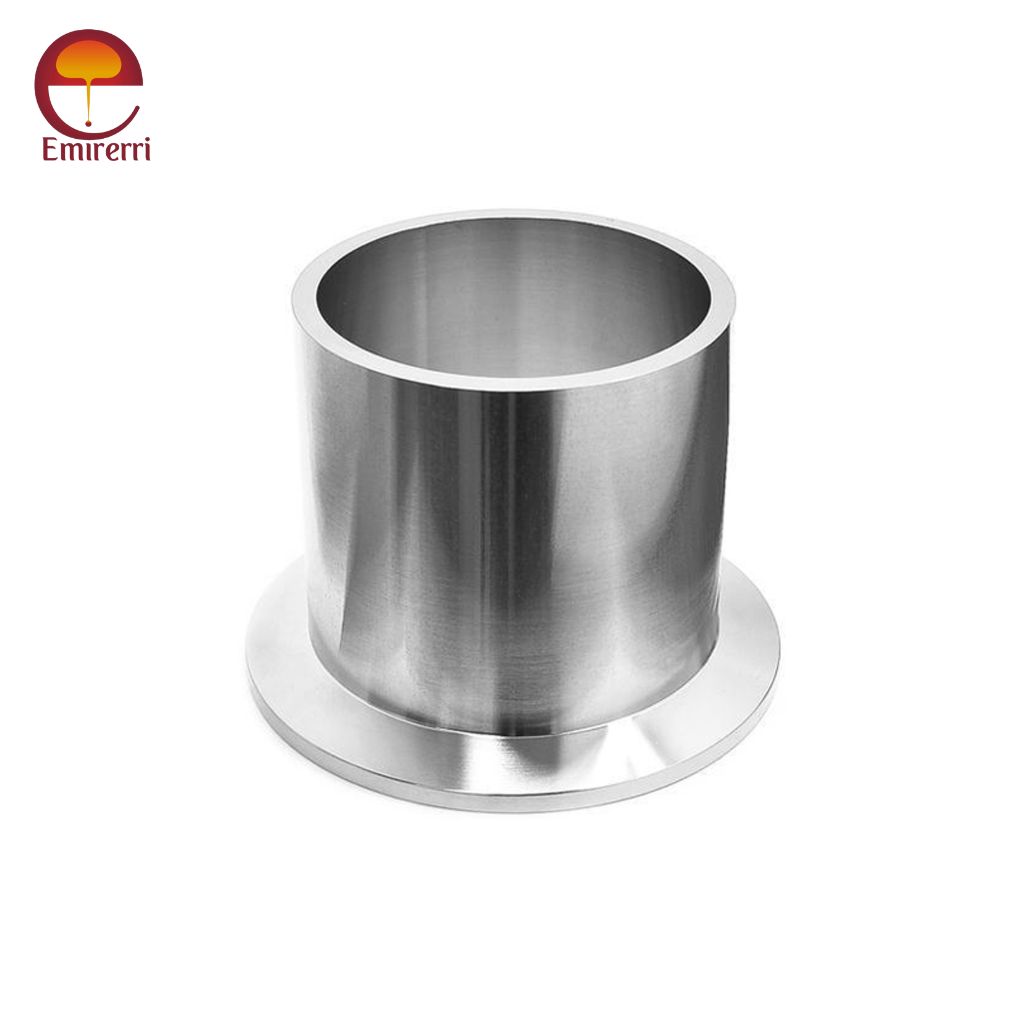

ASTM A815 WP27 Stub Ends

Corrosion Resistance

Superior resistance to chloride and seawater environments

Excellent pitting & crevice corrosion resistance

Highly resistant to stress-corrosion cracking

Suitable for acidic & saline applications

Heat Resistance

Good strength and oxidation resistance up to 300–350°C

Maintains stability and toughness at moderate elevated temperatures

Heat Treatment

Solution annealing: 1040–1120°C

Rapid quenching recommended to maintain duplex structure

Welding

Excellent weldability using TIG / MIG / SMAW

Recommended Filler Metals: ER2594 / E2594

Avoid heat input that may lead to phase imbalance

Fabrication

Good formability and machinability

Higher strength may require stronger forming tools

Recommended to machine in solution-annealed condition

Applications

Offshore oil & gas platforms

Marine & seawater piping systems

Heat exchangers & pressure vessels

Chemical & petrochemical industries

Desalination plants

Pulp & paper industry

Mining & mineral processing

Power generation equipment