ASTM A815 WP33

ASTM A815 WP33 Pipe Fittings

ASTM A815 WP33 is a wrought duplex stainless steel grade manufactured for buttweld pipe fittings under the ASTM A815 specification. These fittings combine the advantages of ferritic and austenitic microstructures to deliver elevated strength, enhanced corrosion resistance and reliable performance in demanding industrial environments. WP33 fittings are ideal for use in chemical, petrochemical, power, offshore and marine applications where both mechanical performance and durability in aggressive service are required.

Key Features

Balanced duplex (ferritic-austenitic) microstructure with high yield strength compared to standard austenitic grades.

Excellent resistance to pitting, crevice corrosion and chloride stress‐corrosion cracking.

Suitable for high‐strength piping systems, enabling thinner wall sections or lighter weight assemblies.

Good weldability and formability, making it practical for fabrication of elbows, tees, reducers, bends and more.

Robust performance in a variety of aggressive environments — chemical processing, seawater, offshore, power, desalination, etc.

ASTM A815 WP33 Specification

| Property | Details |

|---|---|

| Standard | ASTM A815 |

| Grade | WP33 |

| Material | Duplex Stainless Steel Fittings |

| Process | Seamless / Welded / Fabricated |

| Product Type | Elbows, Tees, Reducers, Caps, Stub Ends, Crosses |

| Size Range | 1/2” to 48” NB |

| Pressure Rating | SCH 10S to SCH XXS |

| Dimensions | ASME B16.9 / B16.28 |

| Manufacturing Method | Hot forming / Cold forming / Heat treatment |

| Testing | Hydrostatic / NDT / PMI / Hardness / Tensile |

Equivalent Grade

| Standard | Grade |

|---|---|

| UNS | S39274 (Approx. Reference) |

| ISO / EN | Equivalent Duplex Stainless Category |

| Werkstoff Nr. | ~ |

Available Sizes

| Parameter | Range |

|---|---|

| Size | 1/2″ – 48″ NB |

| Thickness | SCH 10S – XXS |

| Types | Seamless / Welded / Fabricated |

Chemical Composition

| Element | % (Typical) |

|---|---|

| Chromium (Cr) | 25 – 33 |

| Nickel (Ni) | 3.5 – 6.0 |

| Molybdenum (Mo) | 0.5 – 2.5 |

| Nitrogen (N) | 0.20 – 0.30 |

| Carbon (C) | ≤ 0.030 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.030 |

| Sulfur (S) | ≤ 0.020 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 620 MPa |

| Yield Strength | ≥ 450 MPa |

| Elongation | ≥ 25% |

| Hardness | ≤ 290 HBW |

Physical Properties

| Property | Value |

|---|---|

| Density | ~ 7.8 g/cm³ |

| Melting Point | 1350 – 1450°C |

| Thermal Conductivity | ~ 14 W/m-K |

| Electrical Resistivity | ~ 0.85 μΩ-m |

Types of ASTM A815 WP33 Fittings

ASTM A815 WP33 Elbow

ASTM A815 WP33 Tee

ASTM A815 WP33 Reducers

ASTM A815 WP33 Caps

ASTM A815 WP33 Cross Fittings

ASTM A815 WP33 Nipples

ASTM A815 WP33 Couplings

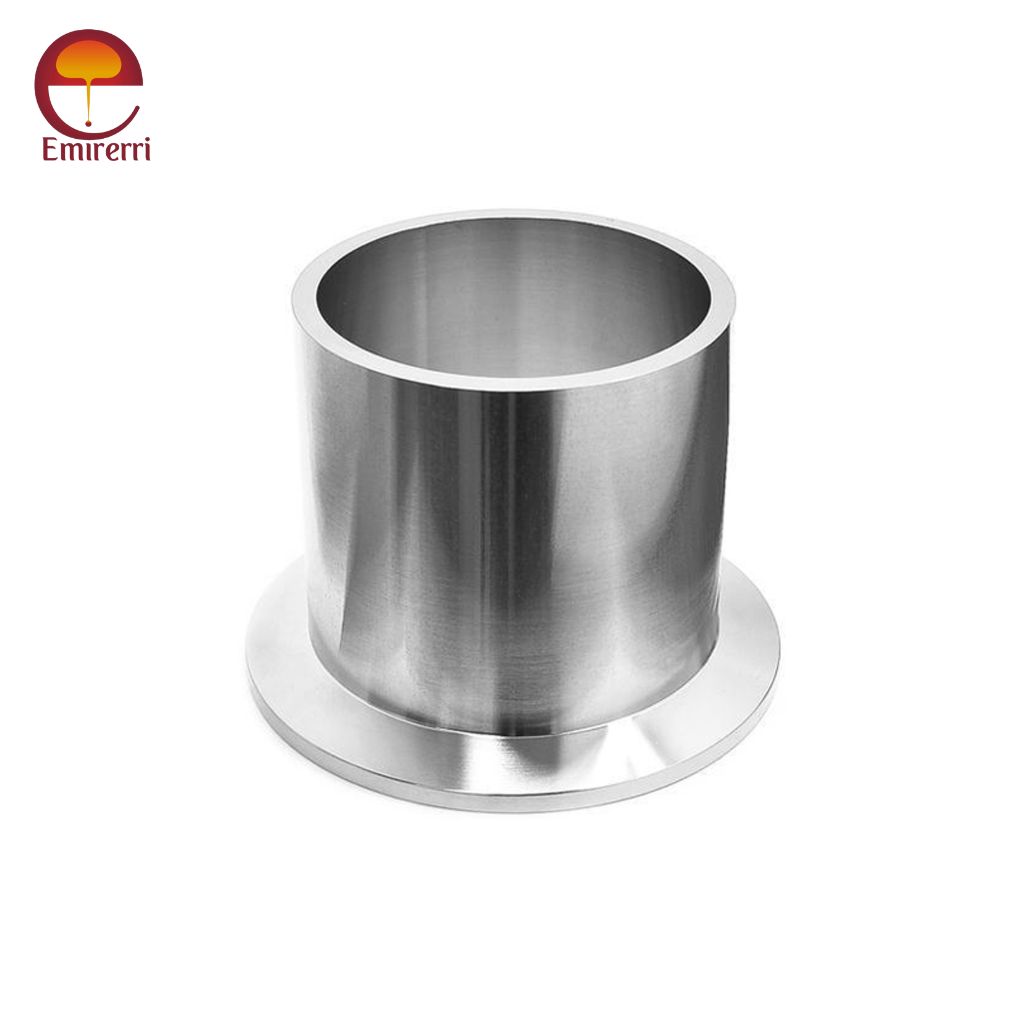

ASTM A815 WP33 Stub Ends

Corrosion Resistance

WP33 duplex stainless steel fittings exhibit excellent resistance in chloride‐bearing environments, seawater, brine, and many chemical process fluids. Their duplex microstructure reduces the risk of chloride stress‐corrosion cracking, while high alloy content enhances pitting and crevice corrosion resistance. These properties make WP33 a robust choice where longevity and reliability under corrosive attack are critical.

Heat Resistance

Duplex stainless steels such as WP33 maintain good mechanical and corrosion resistance up to moderate elevated temperatures (~300-350 °C). Beyond this range, careful consideration is required regarding phase stability, intermetallic formation and strength/ductility retention. WP33 fittings are suitable for many heat‐exposed systems, provided thermal design and material limits are respected.

Heat Treatment

Solution annealing is typically performed in the range ~ 1020-1120 °C followed by rapid quenching to maintain duplex structure.

Heat treatment should be verified by mill certificate.

Avoid prolonged exposure in the temperature range where intermetallic phases (sigma, chi) may form (~300-900 °C) for extended periods, unless allowed by design.

Welding

WP33 duplex stainless steel fittings can be welded using standard methods (TIG, MIG, SMAW). Key recommendations:

Use matching or appropriate duplex stainless steel filler metals.

Ensure appropriate heat input and interpass temperature control to preserve the duplex phase balance (~50% ferrite / ~50% austenite).

After welding, inspection (visual, NDT) and where required post‐weld treatment or solution anneal may be specified by client or design code.

Fabrication

Forming, bending, machining and fabrication should follow stainless duplex best practices: use dedicated tooling to avoid cross‐contamination, sharp cutting tooling to reduce work‐hardening.

Cold forming is possible but due to high strength of duplex steel, spring‐back and tool wear must be managed.

Welding and fabrication must preserve material’s duplex structure and avoid excessive phase imbalance that could degrade corrosion resistance or toughness.

Applications

Offshore oil & gas production & subsea systems

Chemical processing plants & petrochemicals

Seawater intake, desalination and marine piping systems

Power generation plants

Pulp & paper processing

Flue gas desulfurization and emissions control

Heat exchangers, pressure vessels and high-strength pipe networks

Industrial water treatment and brine handling