ASTM A815 WP429

ASTM A815 WP429 Wrought Stainless Steel Pipe Fittings

ASTM A815 WP429 refers to wrought martensitic stainless steel butt-weld pipe fittings made from Grade 429 stainless steel. This steel grade offers excellent resistance to corrosion, oxidation, and scaling at elevated temperatures, along with good mechanical strength and moderate toughness.

With improved performance over standard ferritic grades and designed to withstand high-temperature exhaust, furnace, and industrial chemical environments, ASTM A815 WP429 fittings are widely used in chemical plants, power stations, heat treatment systems, and thermal processing equipment.

These pipe fittings offer excellent weldability, dimensional accuracy, and long-term durability, making them suitable for demanding industrial fluid-handling systems.

Key Features

Manufactured from martensitic stainless steel (Grade 429)

Excellent scaling and oxidation resistance at high temperatures

Good chloride stress corrosion resistance

Higher mechanical strength than ferritic grades

Suitable for high-temperature exhaust and furnace components

Good wear and abrasion resistance

Precise fit and dimensional stability for pressure pipelines

Specification

| Property | Details |

|---|---|

| Standard | ASTM A815 |

| Grade | WP429 |

| Material Type | Wrought Martensitic Stainless Steel |

| Form | Butt-Weld Pipe Fittings |

| Sizes | ½” to 48” (DN15–DN1200) |

| Schedule | SCH 10 to SCH XXS |

| Class | WP – Wrought Fittings |

| Surface Finish | Mill Finished / Pickled & Passivated |

| Manufacturing Method | Formed, Welded / Seamless |

Equivalent Grade

| Standard | Grade |

|---|---|

| UNS | S42900 |

| AISI | 429 |

| ASTM | A815 WP429 |

| EN / W.Nr | Equivalent to 1.4000 / Similar martensitic grade |

| JIS | Equivalent martensitic stainless grade reference |

Note: Grade matches UNS S42900 martensitic stainless steel.

Available Sizes

Size Range: ½” to 48”

Thickness: SCH 10 – XXS

End Type: Beveled ends (BW fittings)

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 14.0 – 16.0 |

| Carbon (C) | ≤ 0.12 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 1.0 |

| Nickel (Ni) | ≤ 0.5 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≤ 0.030 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 450 MPa |

| Yield Strength | ≥ 275 MPa |

| Elongation | ≥ 20% |

| Hardness | ≤ 223 HBW |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.7 – 7.8 g/cm³ |

| Melting Range | 1420°C – 1510°C |

| Modulus of Elasticity | ~200 GPa |

| Thermal Conductivity | Higher than austenitic grades |

| Thermal Expansion | Lower than 300-series stainless steel |

Types of ASTM A815 WP429 Fittings

ASTM A815 WP429 Elbow

ASTM A815 WP429 Tee

ASTM A815 WP429 Reducers

ASTM A815 WP429 Caps

ASTM A815 WP429 Cross Fittings

ASTM A815 WP429 Nipples

ASTM A815 WP429 Couplings

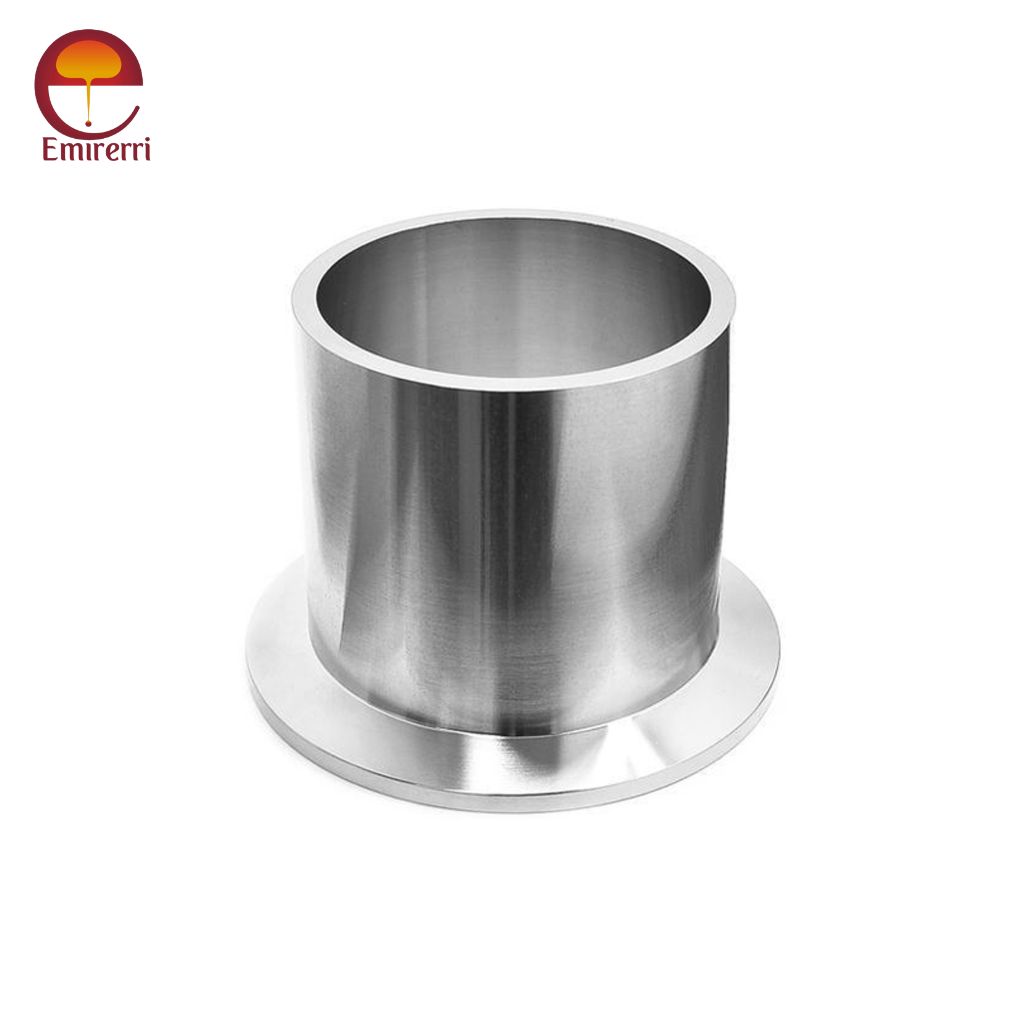

ASTM A815 WP429 Stub Ends

Corrosion Resistance

ASTM A815 WP429 offers:

Good corrosion resistance in mild acids & organic compounds

Strong resistance to oxidation & scaling up to 850°C

Good performance in exhaust gas & heat-treating environments

Effective in mild chloride environments with proper design

Heat Resistance

Resistant to oxidation and scale formation up to ~850°C

Suitable for high-temperature exhaust, furnace tubes, heat treatment areas

Maintains structural integrity under thermal cycling

Heat Treatment

Typically supplied in annealed or tempered condition

Annealing: 820°C – 900°C

Air cool after annealing

Tempering may improve ductility and stress relief

Welding

Weldable using standard techniques for martensitic grades

Preheat recommended: 150°C – 300°C

Post-weld heat treatment advised to restore corrosion resistance & strength

Suggested filler: Matching 429 grade or similar martensitic filler

Fabrication

Machinable & formable with appropriate tooling

Recommended to avoid severe cold working without intermediate annealing

Better machinability than austenitic grades

Applications

Power Plants & Boiler Systems

Exhaust & Flue Gas Systems

Heat Treatment Furnaces

Petrochemical Equipment

Thermal Processing Units

Gas Turbine Components

Industrial Heaters & Burners

Automotive & Industrial Exhaust Systems

Chemical Processing Equipment