ASTM A815 WPS 32760

ASTM A815 WPS 32760 Super Duplex Stainless Steel Pipe Fittings

ASTM A815 WPS 32760 refers to wrought super duplex stainless steel pipe fittings manufactured according to ASTM A815 Standards, with the material grade UNS S32760. These fittings are engineered for high-pressure, highly corrosive, and chloride-rich environments, offering exceptional strength, superior corrosion resistance, and excellent resistance to stress corrosion cracking.

UNS S32760 contains 25% Cr, 7% Ni, 3.5% Mo, and added copper & tungsten, providing a balanced microstructure of austenite + ferrite, making it one of the strongest materials for industrial piping applications.

Key Features

Super duplex stainless steel with superior strength

High resistance to pitting, crevice corrosion & chloride stress corrosion cracking

Excellent performance in seawater & marine applications

Twice the strength of conventional stainless steels (304 / 316)

High impact toughness even at sub-zero temperatures

Excellent weldability and fatigue resistance

Long service life in extreme environments

Technical Specification

| Specification | Details |

|---|---|

| Standard | ASTM A815 / A815M |

| Grade | WPS 32760 |

| Material | Super Duplex Stainless Steel |

| UNS | S32760 |

| Manufacturing Class | WPS – Welded, Pickled, Solution Annealed |

| Form | Butt Weld Pipe Fittings |

| Standards | ANSI / ASME B16.9, B16.28, MSS SP-43 / SP-75 |

| Type | Wrought Fittings |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | S32760 |

| EN | 1.4501 |

| ASTM | A182 F55 / A276 S32760 |

| DIN | X2CrNiMoCuWN25-7-4 |

| ISO | 25Cr super duplex |

| Common Trade Name | Zeron® 100 |

Available Sizes

NPS: ½” to 24”

Schedules: SCH 10S to SCH 160 / XXS

Forms Available: Seamless / Welded / Fabricated

Chemical Composition

| Element | % |

|---|---|

| Chromium (Cr) | 24.0 – 26.0 |

| Nickel (Ni) | 6.0 – 8.0 |

| Molybdenum (Mo) | 3.0 – 4.0 |

| Tungsten (W) | 0.5 – 1.0 |

| Copper (Cu) | 0.5 – 1.0 |

| Nitrogen (N) | 0.2 – 0.3 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Carbon (C) | ≤ 0.03 |

| Phosphorus (P) | ≤ 0.035 |

| Sulfur (S) | ≤ 0.02 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥ 750 MPa |

| Yield Strength | ≥ 550 MPa |

| Elongation | ≥ 25% |

| Impact Toughness | Excellent, even at -50°C |

| Hardness | ≤ 310 HB |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.8 g/cm³ |

| Melting Range | ~1450°C |

| Thermal Conductivity | 14.0 W/m-K |

| Modulus of Elasticity | ~200 GPa |

Types of ASTM A815 WPS 32760 Fittings

ASTM A815 WPS 32760 Elbow

ASTM A815 WPS 32760 Tee

ASTM A815 WPS 32760 Reducers

ASTM A815 WPS 32760 Caps

ASTM A815 WPS 32760 Cross Fittings

ASTM A815 WPS 32760 Nipples

ASTM A815 WPS 32760 Couplings

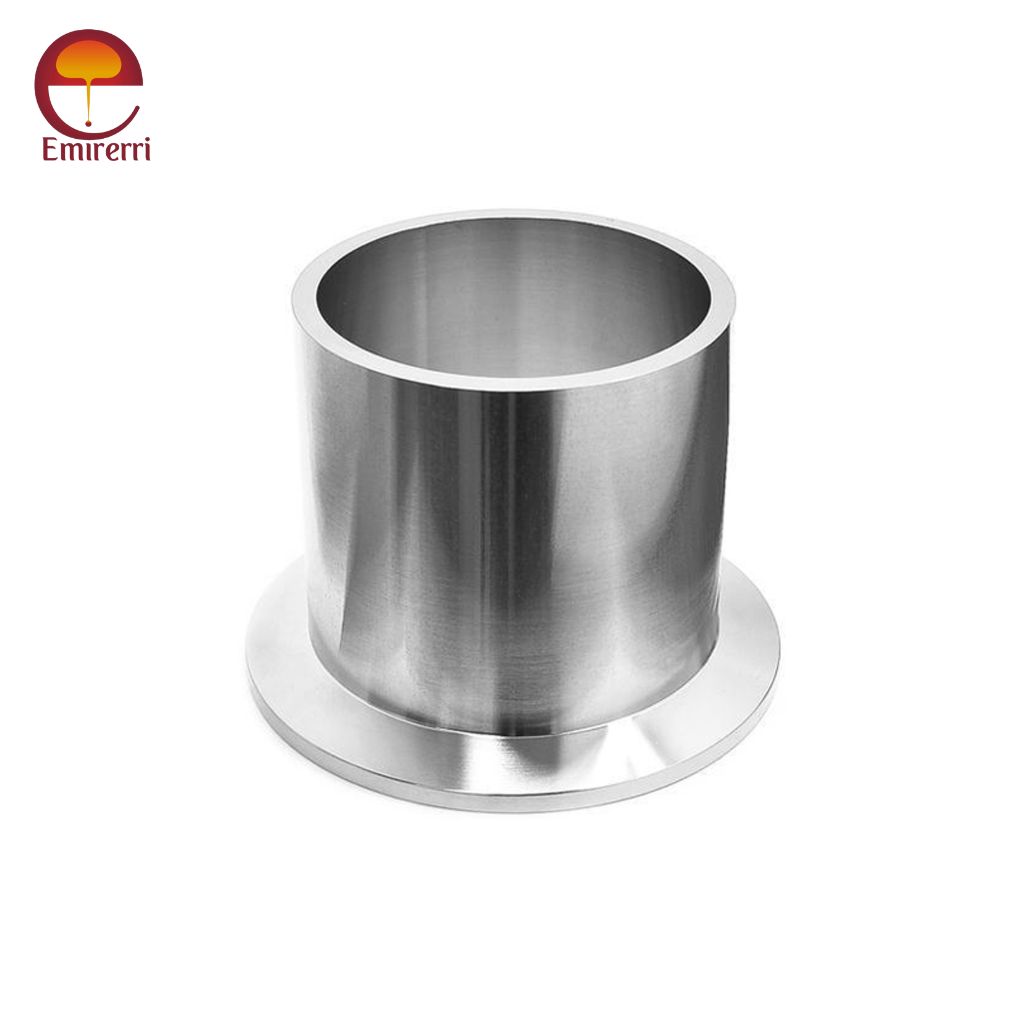

ASTM A815 WPS 32760 Stub Ends

Corrosion Resistance

Seawater corrosion

Chloride stress cracking

Pitting & crevice corrosion (PREN > 40)

Sulfide stress cracking in sour service (NACE MR0175)

Acidic & alkaline chemical exposure

Heat Resistance

Suitable up to 300°C continuous service

Better thermal fatigue resistance than austenitic steel

Retains strength at elevated temperatures

Heat Treatment

| Treatment | Description |

|---|---|

| Solution Annealing | 1020°C – 1120°C |

| Cooling | Rapid water quench |

| Hardening | Not hardenable by heat treatment (work hardened only) |

Welding

Good weldability with proper procedures

Recommended filler metals: ER2594, E2594

Preheat not required; interpass ≤ 150°C

Post-weld solution annealing recommended for critical service

Fabrication

Good machinability with high-speed tools

Avoid excessive cold working without subsequent heat treatment

Bending & forming possible with proper technique

Applications

Offshore oil & gas platforms

Subsea equipment & pipelines

Chemical & petrochemical plants

Desalination & seawater intake systems

Pulp & paper industry

Heat exchangers & pressure vessels

Marine engineering components