ASTM A815 WP33

ASTM A815 WPS32550 Duplex Stainless Steel Pipe Fittings

ASTM A815 WPS32550 refers to duplex stainless steel pipe fittings manufactured under the ASTM A815 standard, which covers wrought ferritic, austenitic, and duplex (austenitic/ferritic) stainless steel fittings for pressure applications. Grade WPS32550 (UNS S32550, commonly known as Duplex 2550) offers a unique combination of high strength, excellent corrosion resistance, and superior mechanical properties.

These fittings are widely used in highly corrosive environments such as marine, offshore, chemical processing, and oil & gas industries, where both high strength and resistance to pitting and crevice corrosion are required.

Key Features

Excellent resistance to pitting, crevice, and stress corrosion cracking.

High mechanical strength and impact toughness.

Good weldability and formability.

Superior resistance to chloride-containing environments.

Excellent performance in acidic and alkaline media.

Enhanced durability under high pressure and high temperature conditions.

Specification

| Standard | ASTM A815 / ASME SA815 |

|---|---|

| Grade | WPS32550 |

| Material Type | Duplex Stainless Steel |

| UNS Number | S32550 |

| W.Nr. | 1.4507 |

| Form | Elbows, Tees, Reducers, Caps, Stub Ends, Crosses |

| Manufacturing Process | Seamless / Welded / Fabricated |

| Size Range | ½” NB to 48” NB |

| Schedule | SCH 10S to SCH 160 / XXS |

| Standard Ends | Beveled, Plain, Threaded, or Customized |

Equivalent Grades

| Standard | Grade |

|---|---|

| ASTM / ASME | UNS S32550 |

| EN | X2CrNiMoCuWN25-7-4 |

| W.Nr | 1.4507 |

| Trade Name | Ferralium 255, Duplex 2550 |

Available Sizes

Seamless Fittings: ½” to 24” NB

Welded Fittings: ½” to 48” NB

Thickness: SCH 10S, 40S, 80S, 160, XXS

Custom sizes available upon request

Chemical Composition

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 24.0 – 27.0 |

| Nickel (Ni) | 4.5 – 6.5 |

| Molybdenum (Mo) | 2.9 – 3.9 |

| Copper (Cu) | 1.5 – 2.5 |

| Tungsten (W) | 0.5 – 1.0 |

| Nitrogen (N) | 0.10 – 0.25 |

| Manganese (Mn) | ≤ 1.5 |

| Silicon (Si) | ≤ 1.0 |

| Carbon (C) | ≤ 0.04 |

| Phosphorus (P) | ≤ 0.03 |

| Sulfur (S) | ≤ 0.02 |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 750 MPa (min) |

| Yield Strength (0.2% Proof) | 550 MPa (min) |

| Elongation | 25% (min) |

| Hardness (Brinell) | ≤ 310 HB |

| Impact Toughness | Excellent (up to -46°C) |

Physical Properties

| Property | Value |

|---|---|

| Density | 7.80 g/cm³ |

| Melting Point | 1370–1420°C |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 14 W/m·K |

| Electrical Resistivity | 0.8 µΩ·m at 20°C |

Types of ASTM A815 WPS32550 Fittings

ASTM A815 WPS32550 Elbow

ASTM A815 WPS32550 Tee

ASTM A815 WPS32550 Reducers

ASTM A815 WPS32550 Caps

ASTM A815 WPS32550 Cross Fittings

ASTM A815 WPS32550 Nipples

ASTM A815 WPS32550 Coupling

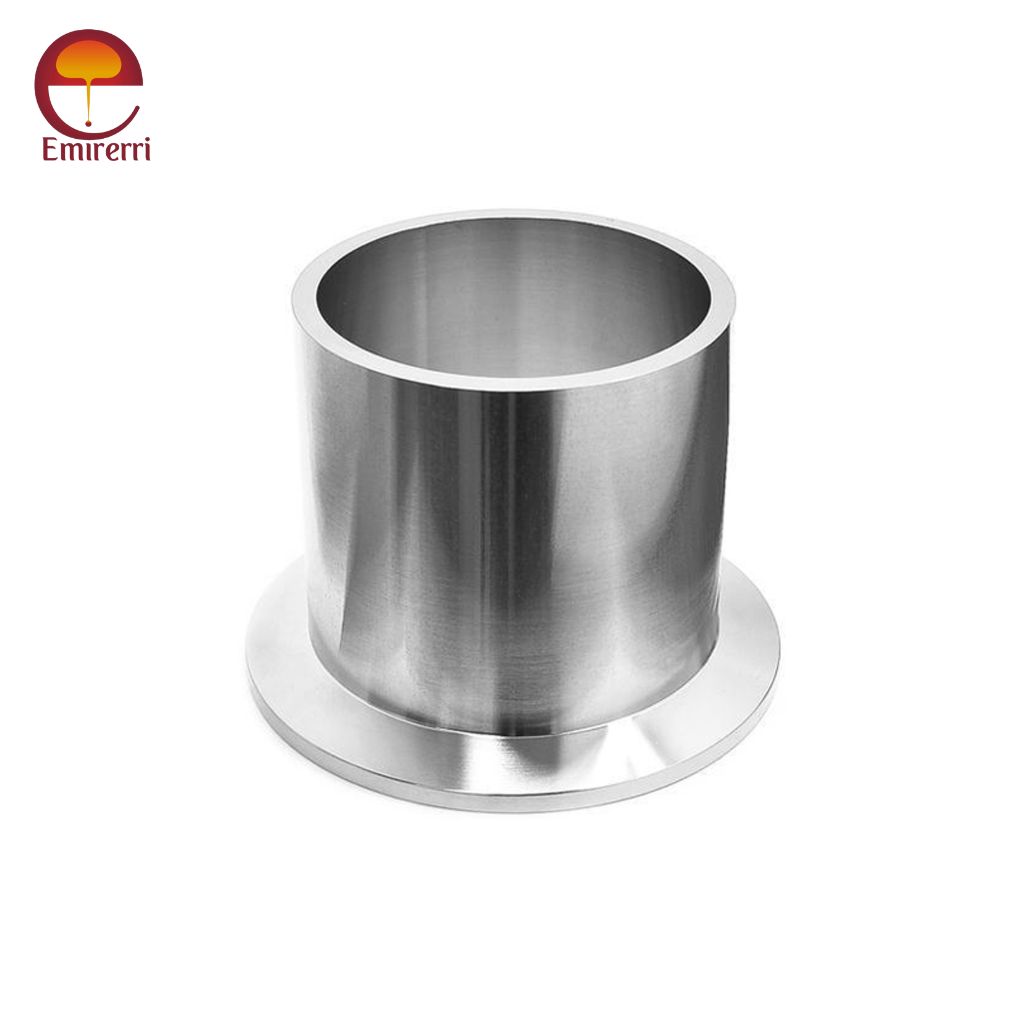

ASTM A815 WPS32550 Stub Ends

Corrosion Resistance

ASTM A815 WPS32550 fittings offer outstanding resistance to:

Pitting & Crevice Corrosion in chloride environments.

Stress Corrosion Cracking in seawater and acidic conditions.

Sulphuric Acid and Phosphoric Acid exposure.

Oxidizing & Reducing Agents, maintaining structural integrity over time.

This makes them ideal for chemical processing, desalination plants, and marine systems.

Heat Resistance

Exhibits high strength and oxidation resistance up to ~300°C (572°F).

Suitable for continuous service in moderate temperature ranges.

Maintains excellent toughness and resistance to thermal fatigue.

Heat Treatment

Solution Annealing: 1120–1180°C followed by rapid water quenching.

Heat treatment helps restore duplex structure and corrosion resistance.

Not suitable for hardening by heat treatment.

Welding

Excellent weldability using GTAW (TIG), SMAW (Stick), or GMAW (MIG) methods.

Low heat input is recommended to preserve the duplex microstructure.

Post-weld solution annealing can enhance corrosion resistance.

Fabrication

Good formability and machinability with carbide tools.

Cold forming possible with moderate force.

Preheating not required before forming or welding.

Applications

Chemical Processing Plants

Oil & Gas Exploration

Marine & Offshore Engineering

Pulp and Paper Industry

Desalination Plants

Power Generation Systems

Heat Exchangers and Pressure Vessels