Butt Weld Steel Elbow

Butt Weld Steel Elbow (Stainless, Carbon, Alloy Steel)

A steel elbow is a pipe fitting used to connect two pipes at an angle, typically 45° or 90°, to change the direction of flow in a piping system. They are commonly used in plumbing, heating, cooling, and various industrial applications. Steel elbows come in different types based on material, connection method, and angle

| Attribute | Description |

|---|---|

| Product Name | Butt Weld Steel Elbow |

| Material | Carbon Steel (e.g., ASTM A234 WPB), Stainless Steel (e.g., ASTM A403 WP304/304L, WP316/316L), Alloy Steel |

| Nominal Pipe Size (NPS) | 1/2″ to 48″ (DN15 to DN1200) |

| Angle | 45°, 90°, 180° (other angles available as bends) |

| Radius Type | Long Radius (LR, 1.5x pipe diameter), Short Radius (SR, 1x pipe diameter) |

| Wall Thickness | Schedule 5S, 10, 10S, 20, 40, STD, 80, XS, XXS, 160 |

| Connection Type | Butt Weld (beveled or plain ends for welding) |

| Standards | ASME B16.9, MSS SP-43, ASTM A403 (SS), ASTM A234 (CS), ANSI B16.9 |

| Applications | Piping systems for changing flow direction in industries like oil and gas, chemical processing, HVAC, food and beverage, pharmaceutical, and semiconductor |

| Surface Finish | Black (carbon steel), Polished (sanitary SS, e.g., 32Ra, 20Ra, 15Ra), Unpolished |

| Welding Technique | TIG (Tungsten Inert Gas) fusion weld, 100% penetration for external welds, 60-75% for internal welds to minimize warping |

| Key Features | Leak-proof, high strength, corrosion resistance (SS), cost-effective (CS), seamless or welded options |

| Certifications | 3-A Sanitary Standards (for food/beverage), Material certifications available upon request |

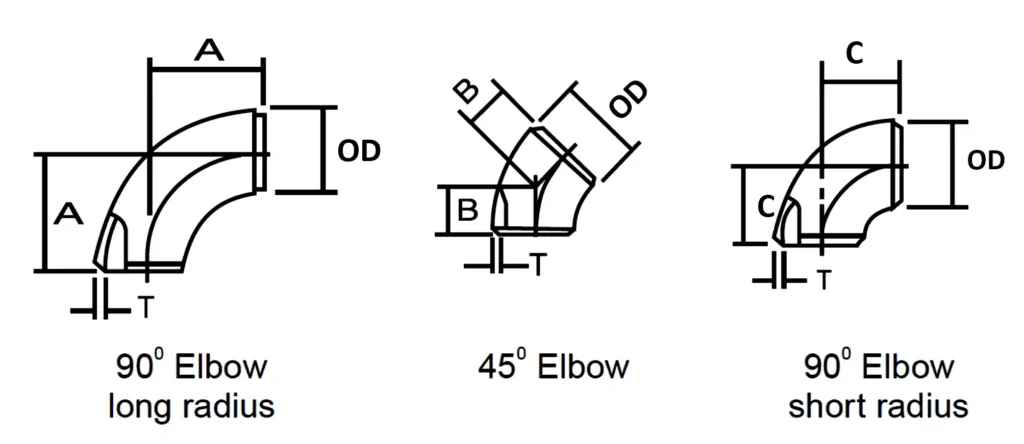

Butt Weld Steel Elbow Dimension

| NPS (Inches) | Outside Diameter (OD) (Inches) | 90° Long Radius Center-to-End (A) (Inches) | 90° Short Radius Center-to-End (B) (Inches) | 45° Long Radius Center-to-End (C) (Inches) | Approx. Weight (90° LR, Schedule 40) (lbs) |

|---|---|---|---|---|---|

| 1/2 | 0.84 | 1.50 | 1.00 | 0.62 | 0.1 |

| 3/4 | 1.05 | 1.50 | 1.12 | 0.69 | 0.1 |

| 1 | 1.32 | 1.50 | 1.12 | 0.75 | 0.2 |

| 1-1/4 | 1.66 | 1.88 | 1.25 | 0.94 | 0.3 |

| 1-1/2 | 1.90 | 2.25 | 1.50 | 1.12 | 0.4 |

| 2 | 2.38 | 3.00 | 2.00 | 1.50 | 0.6 |

| 2-1/2 | 2.88 | 3.75 | 2.50 | 1.88 | 1.0 |

| 3 | 3.50 | 4.50 | 3.00 | 2.25 | 1.4 |

| 3-1/2 | 4.00 | 5.25 | 3.50 | 2.62 | 1.8 |

| 4 | 4.50 | 6.00 | 4.00 | 3.00 | 2.3 |

| 5 | 5.56 | 7.50 | 5.00 | 3.75 | 3.6 |

| 6 | 6.62 | 9.00 | 6.00 | 4.50 | 5.0 |

| 8 | 8.62 | 12.00 | 8.00 | 6.00 | 8.8 |

| 10 | 10.75 | 15.00 | 10.00 | 7.50 | 14.1 |

| 12 | 12.75 | 18.00 | 12.00 | 9.00 | 20.4 |

| 14 | 14.00 | 21.00 | 14.00 | 10.50 | 26.5 |

| 16 | 16.00 | 24.00 | 16.00 | 12.00 | 34.5 |

| 18 | 18.00 | 27.00 | 18.00 | 13.50 | 43.7 |

| 20 | 20.00 | 30.00 | 20.00 | 15.00 | 54.0 |

| 22 | 22.00 | 33.00 | 22.00 | 16.50 | 65.0 |

| 24 | 24.00 | 36.00 | 24.00 | 18.00 | 77.5 |

| 26 | 26.00 | 39.00 | 26.00 | 19.50 | 91.0 |

| 28 | 28.00 | 42.00 | 28.00 | 21.00 | 106.0 |

| 30 | 30.00 | 45.00 | 30.00 | 22.50 | 123.0 |

| 32 | 32.00 | 48.00 | 32.00 | 24.00 | 141.0 |

| 34 | 34.00 | 51.00 | 34.00 | 25.50 | 160.0 |

| 36 | 36.00 | 54.00 | 36.00 | 27.00 | 180.0 |

| 38 | 38.00 | 57.00 | 38.00 | 28.50 | 202.0 |

| 40 | 40.00 | 60.00 | 40.00 | 30.00 | 225.0 |

| 42 | 42.00 | 63.00 | 42.00 | 31.50 | 250.0 |

| 44 | 44.00 | 66.00 | 44.00 | 33.00 | 277.0 |

| 46 | 46.00 | 69.00 | 46.00 | 34.50 | 305.0 |

| 48 | 48.00 | 72.00 | 48.00 | 36.00 | 335.0 |

Types of Butt Weld Steel Elbow

1. Based on Angle:

45° Elbow – For slight direction changes

90° Elbow – Most common for right-angle turns

180° Elbow – For complete reversal in flow direction

2. Based on Radius:

Short Radius (SR) Elbow

Radius = 1 × pipe diameter (R = 1D)

Used in tight spaces, higher turbulence

Long Radius (LR) Elbow

Radius = 1.5 × pipe diameter (R = 1.5D)

Smooth flow, preferred in process piping

3. Based on End Type:

Bevel End Elbow – For butt welding

Plain End Elbow – For socket or slip-on connection

Threaded Elbow – Rare in butt-weld but used in small-bore threaded systems

4. Based on Manufacturing:

Seamless Elbow – No weld, stronger

Welded Elbow – Welded from plates or pipes, cost-effective for large sizes

Application

Direction change in pipelines (45°, 90°, 180° bends)

Oil & gas transportation systems

Petrochemical & chemical processing

Water supply & drainage lines

Power plants & boiler systems

HVAC & fire protection piping

Marine & offshore piping systems