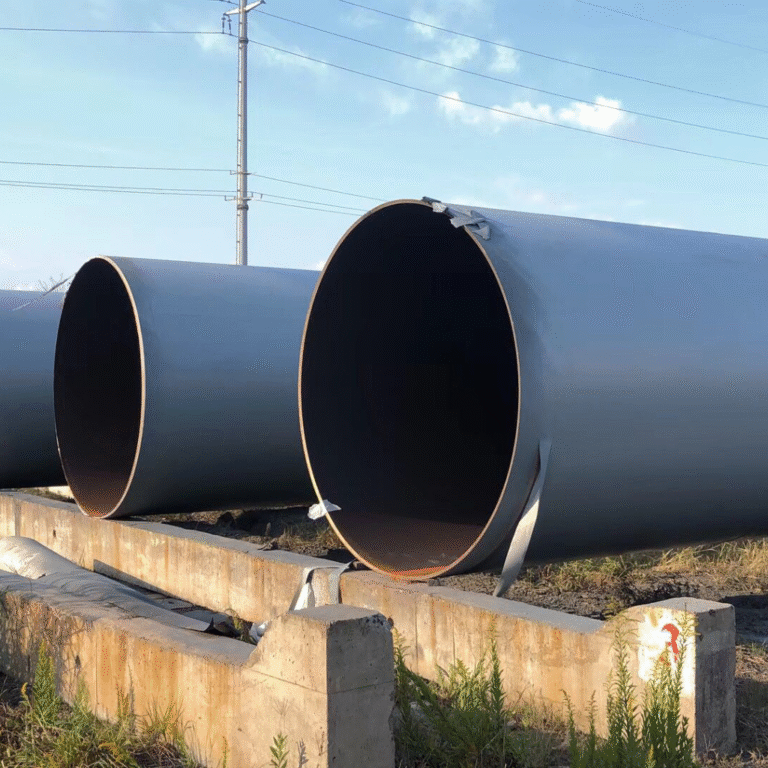

HFIW Pipe

High-Frequency Induction Welded (HFIW) pipes

High-Frequency Induction Welded (HFIW) pipes are widely used in industries that demand strength, reliability, and precision. Known for their superior weld quality and cost-effectiveness, HFIW steel pipes are extensively applied in oil & gas, water transmission, construction, and automotive industries.

At Emirerri Steel, we manufacture and supply premium-quality HFIW pipes that meet international standards such as API, ASTM, and EN. Our pipes are trusted for their dimensional accuracy, smooth surface finish, and long-lasting performance in critical applications.

What is an HFIW Pipe?

An HFIW pipe is produced using a high-frequency induction welding process, where an induction coil generates a strong electromagnetic field that heats the edges of the strip. The heated edges are then forged together under pressure, forming a weld without using any filler material.

This advanced process ensures that the weld zone has high strength and durability, making HFIW steel pipes an ideal choice for both structural and fluid transportation applications.

Key Features of HFIW Pipe

High weld strength and consistency

Smooth internal and external weld seam

Cost-effective production with high efficiency

Suitable for both low and high-pressure applications

Wide range of diameters and thicknesses available

No filler material required, ensuring a clean weld

Manufacturing Process of HFIW Pipe

The production of HFIW welded pipe involves the following steps:

Raw Material Selection – Hot-rolled steel strips or coils are prepared.

Forming – The strip is shaped into a cylindrical form.

High-Frequency Induction Welding – The edges of the strip are heated and fused under pressure.

Sizing & Shaping – Pipes are sized and shaped for dimensional accuracy.

Non-Destructive Testing – Ultrasonic and eddy current testing ensure weld integrity.

Finishing – Pipes are cut to desired lengths and undergo surface treatment if required.

Applications of HFIW Steel Pipe

Thanks to their versatility and cost-effectiveness, HFIW pipes are used in a wide range of industries:

Oil & Gas Transmission – Pipelines for crude oil, petroleum products, and natural gas.

Water Supply & Drainage – Transport of potable water, irrigation systems, and wastewater pipelines.

Construction Industry – Structural supports, scaffolding, and piling.

Automotive Industry – Components requiring precision and strength.

Mechanical & Engineering Use – Conveyor rollers, precision tubes, and general engineering.

Advantages of HFIW Pipe

Strong Weld Quality – High-frequency induction welding ensures uniform strength.

High Productivity – Suitable for mass production with consistent quality.

Cost Efficiency – Lower production costs compared to seamless pipes.

Dimensional Accuracy – Smooth finish with precise diameter control.

Wide Availability – Available in different grades of carbon steel and stainless steel.

Standards & Specifications

Our HFIW pipes are manufactured in compliance with international standards:

API 5L – Line pipe for petroleum and natural gas industries

ASTM A53 / A500 – Structural and mechanical use

EN 10217 / EN 10219 – European standards for welded steel pipes

IS 1161 / IS 1239 – Indian standards for mild steel and structural pipes

Why Choose Emirerri Steel for HFIW Steel Pipes?

Advanced Production Facilities – Equipped with high-frequency welding machines.

Quality Assurance – Each pipe undergoes strict non-destructive testing.

Customization Options – Tailored to meet specific industry requirements.

Global Reach – Supplying to clients across oil & gas, water, and construction industries worldwide.

Competitive Pricing – Delivering reliable solutions at cost-effective rates.