Long Stub End

Long Stub End

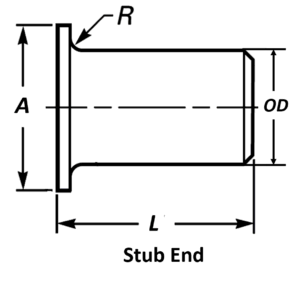

A Long Stub End is a type of pipe fitting used in piping systems to facilitate easy disconnection for inspection, cleaning, or replacement. It is typically used with a lap joint flange and allows the flange to rotate freely for easy bolt alignment.

| Attribute | Description |

|---|---|

| Product Name | Long Stub End |

| Definition | A pipe fitting with a longer hub length, flared at one end for connection with a lap joint flange, and the other end welded to a pipe of similar diameter and wall thickness. |

| Standards | ASME/ANSI B16.9, ASME B16.28, MSS SP-43, MSS SP-75, BS1640, DIN 2642, EN 1092-1 Type 35/36 |

| Types | Seamless, ERW, Welded, Fabricated |

| Sizes | 1/2″ NB to 48″ NB (seamless: 1/2″ to 10″; welded: 1/2″ to 48″) |

| Wall Thickness | Schedule 5S, 10S, 20S, 40S, 80S, STD, XS, XXS, and others |

| Materials | – Stainless Steel: ASTM A403 WP304/304L, WP316/316L, SA/A 774 WP-S, WP-W, WP-WX – Carbon Steel: ASTM A234 WPB, WPHY 42-70, ASTM A420 WPL3/WPL6 – Alloy Steel: ASTM A234 WP1, WP5, WP9, WP11, WP22, WP91 – Nickel Alloy: Nickel 200/201, Monel 400/500, Inconel 800/825 – Duplex/Super Duplex: ASTM A815 UNS S31803, S32205, S32750, S32950 |

| End Types | Beveled, Grooved, Squared, Flanged, Threaded (for male fittings) |

| Applications | Petroleum, petrochemical, oil and gas, power generation, marine, pollution control, low-pressure industrial systems |

| Key Features | – Longer hub for better connection stability – Used with lap joint flanges for easy alignment and rotation – High mechanical strength and corrosion resistance (material-dependent) – Suitable for high-pressure and low-pressure applications |

| Manufacturing Process | Flared using a flaring machine, cut to length, and machined to match lap joint flange profiles |

| Common Grades | Stainless Steel 304/316L, Carbon Steel WPB, Monel, Inconel, Duplex |

| Price Reference | Contact suppliers for exact pricing (e.g., Skyland Metal, Navstar Steel, RPF India) as prices vary by size, material, and region. Approx. price lists available on request. |

Long Stub End Sizes

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel (OD) (mm/in) | Overall Length (F) (mm/in) | Wall Thickness (Sch) | Hub Diameter (G) (mm/in) |

|---|---|---|---|---|

| 1/2″ | 21.3 / 0.84 | 76.2 / 3.00 | Sch 5S, 10S, 40S, 80S | 35.0 / 1.38 |

| 3/4″ | 26.7 / 1.05 | 76.2 / 3.00 | Sch 5S, 10S, 40S, 80S | 42.9 / 1.69 |

| 1″ | 33.4 / 1.32 | 101.6 / 4.00 | Sch 5S, 10S, 40S, 80S | 50.8 / 2.00 |

| 1-1/4″ | 42.2 / 1.66 | 101.6 / 4.00 | Sch 5S, 10S, 40S, 80S | 63.5 / 2.50 |

| 1-1/2″ | 48.3 / 1.90 | 101.6 / 4.00 | Sch 5S, 10S, 40S, 80S | 73.0 / 2.87 |

| 2″ | 60.3 / 2.38 | 152.4 / 6.00 | Sch 5S, 10S, 40S, 80S | 92.1 / 3.63 |

| 2-1/2″ | 73.0 / 2.88 | 152.4 / 6.00 | Sch 5S, 10S, 40S, 80S | 104.8 / 4.13 |

| 3″ | 88.9 / 3.50 | 152.4 / 6.00 | Sch 5S, 10S, 40S, 80S | 127.0 / 5.00 |

| 4″ | 114.3 / 4.50 | 152.4 / 6.00 | Sch 5S, 10S, 40S, 80S | 157.5 / 6.19 |

| 6″ | 168.3 / 6.63 | 203.2 / 8.00 | Sch 5S, 10S, 40S, 80S | 215.9 / 8.50 |

| 8″ | 219.1 / 8.63 | 203.2 / 8.00 | Sch 5S, 10S, 40S, 80S | 269.9 / 10.63 |

| 10″ | 273.0 / 10.75 | 254.0 / 10.00 | Sch 5S, 10S, 40S, 80S | 323.9 / 12.75 |

| 12″ | 323.8 / 12.75 | 254.0 / 10.00 | Sch 5S, 10S, 40S, 80S | 381.0 / 15.00 |

| 14″ to 48″ | Varies (e.g., 355.6 / 14.00 to 1219.2 / 48.00) | 254.0–304.8 / 10.00–12.00 | Sch 5S, 10S, STD, XS, XXS | Varies per size |

Types of Long Stub Ends

1. Type A Long Stub End

Standard: MSS-SP-43

Design: Has a machined groove on the back face to match the lap joint flange.

Flange Compatibility: Designed specifically for use with standard lap joint flanges.

Common Use: Preferred in stainless steel systems and high-corrosion environments.

2. Type B Long Stub End

Standard: ASME B16.9

Design: Flat back with a square end, no machined groove.

Flange Compatibility: Can be used with slip-on flanges as lap joint flanges.

Common Use: Generally used in carbon steel and low-pressure applications.

3. Type C Long Stub End

Design: Custom-made with short length and less precision

Flange Compatibility: Used with custom flanges or systems with relaxed tolerances.

Common Use: Economical option where perfect flange rotation is not critical.

Applications:

Ideal for systems requiring frequent dismantling

Used in chemical, pharmaceutical, food processing, and power plants

Suitable for corrosive environments due to minimal flange contact with media