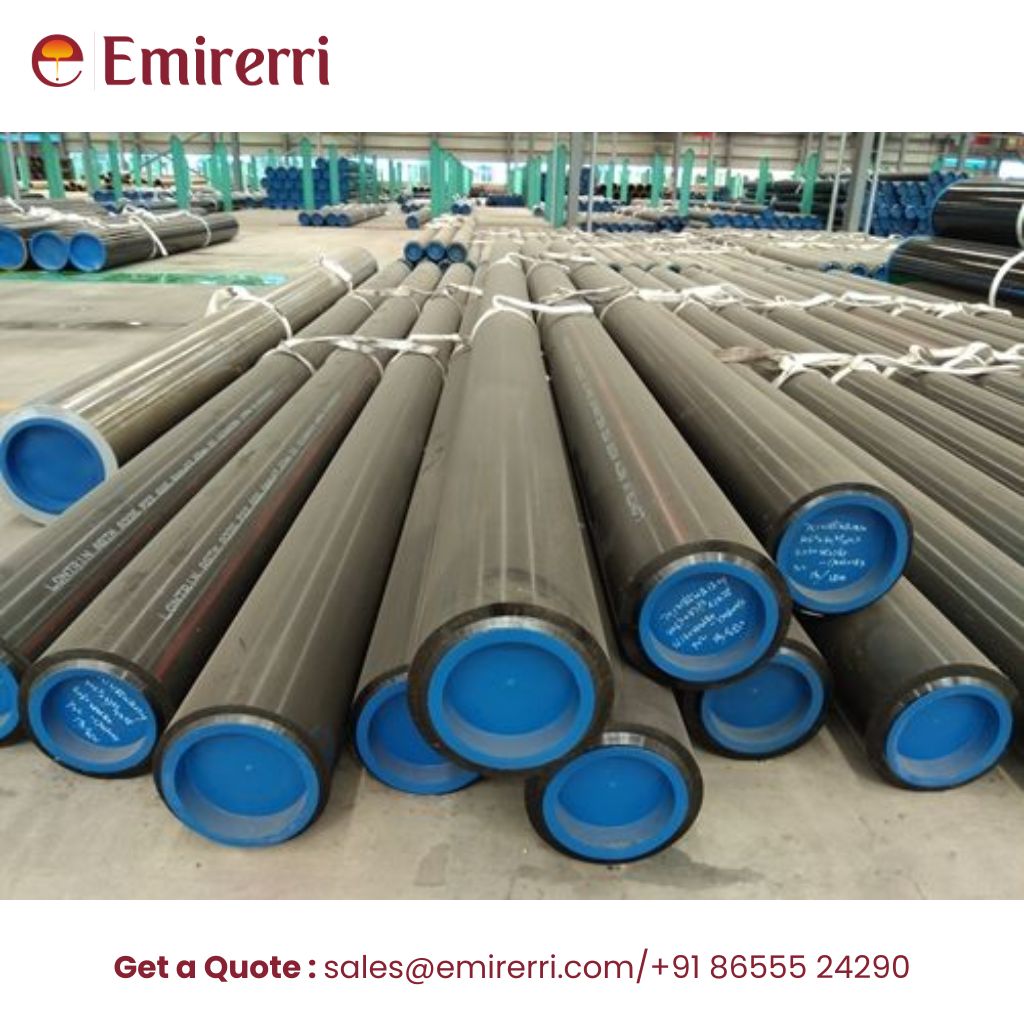

ASTM A106 / SA106 Grade A, B, C Seamless Pipes

At Emirerri Steel, we are a trusted manufacturer, stockist, and global supplier of ASTM A106 / ASME SA106 Grade A, B, and C seamless carbon steel pipes, designed for high-temperature and high-pressure service. Our A106 pipes are widely used in oil and gas, power generation, refineries, boilers, petrochemicals, and construction projects, where superior mechanical properties and durability are critical.

Backed by years of expertise and a strong international presence, we ensure our pipes meet stringent global standards, providing customers with reliable solutions that combine quality, precision, and cost-effectiveness.

Overview of ASTM A106 / SA106 Seamless Pipes

ASTM A106 / SA106 seamless pipes are carbon steel pipes used for high-temperature service in industries requiring excellent resistance to heat and pressure. They are seamless in structure, ensuring leak-proof performance, and are commonly used in conveyance of oil, gas, steam, and fluids under elevated conditions.

- Grade A – Lower strength, good for light-duty applications.

- Grade B – The most widely used grade, offering a balance of strength and ductility.

- Grade C – Higher tensile strength, suitable for critical and demanding operations.

These pipes are suitable for welding, bending, flanging, and forming operations, making them versatile for engineering and industrial applications.

Key Features

- High strength for elevated temperature applications.

- Superior dimensional accuracy and surface finish.

- Excellent toughness and durability under high-pressure service.

- Suitable for bending, flanging, and welding without cracking.

- Available in Hot-Finished and Cold-Drawn (cold-finished) conditions.

ASTM A106 / SA106 Grade A, B, C Chemical Composition

| Element | Grade A (%) | Grade B (%) | Grade C (%) |

|---|---|---|---|

| Carbon (C) | 0.25 max | 0.30 max | 0.35 max |

| Manganese (Mn) | 0.27–0.93 | 0.29–1.06 | 0.29–1.06 |

| Phosphorus (P) | 0.035 max | 0.035 max | 0.035 max |

| Sulfur (S) | 0.035 max | 0.035 max | 0.035 max |

| Silicon (Si) | 0.10 min | 0.10 min | 0.10 min |

ASTM A106 / SA106 Grade A, B, C Chemical Composition

| Property | Grade A | Grade B | Grade C |

|---|---|---|---|

| Tensile Strength (MPa) | 330 min | 415 min | 485 min |

| Yield Strength (MPa) | 205 min | 240 min | 275 min |

| Elongation (%) | 35 | 30 | 30 |

Applications

Our ASTM A106 Gr A, B, C pipes are widely used in industries such as:

- Oil & Gas Pipelines – Transport of crude oil, petroleum, and natural gas.

- Refineries & Petrochemicals – High-pressure piping in processing units.

- Power Plants – Boiler tubes, heat exchangers, and condensers.

- Shipbuilding & Marine Applications – Offshore drilling and ship pipelines.

- Construction & Infrastructure – Piping for water and sewage systems.

- Fertilizer Plants & Chemical Industries – Corrosion and heat-resistant piping.

Reviews

There are no reviews yet.