ASTM A234 WPB Reducer

ASTM A234 WPB reducers are essential components used in piping systems to connect pipes of varying diameters. These reducers are engineered to ensure smooth fluid flow, reduce turbulence, and manage pressure changes effectively. Manufactured using high-quality carbon steel, ASTM A234 WPB reducers are widely utilized in industries such as oil and gas, petrochemicals, power generation, and water treatment. ASTM A234 WPB refers to a standard specification for wrought carbon steel and alloy steel fittings of seamless and welded construction. WPB stands for “Wrought Pipe Bending,” indicating the material is designed to withstand bending, forming, and welding processes.

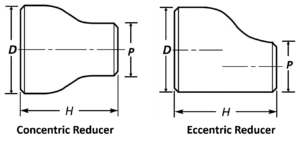

A234 WPB Concentric and Eccentric Reducer Dimensions

| NOMINAL PIPE SIZE | OUTSIDE DIAMETER | END TO END | |

| Inch | D | P | H |

| 3/4 x 1/2 | 26.7 | 21.3 | 38 |

| 3/4 x 3/8 | 26.7 | 17.1 | 38 |

| 1 x 3/4 | 33.4 | 26.7 | 51 |

| 1 x 1/2 | 33.4 | 21.3 | 51 |

| 1 1/4 x 1 | 42.2 | 33.4 | 51 |

| 1 1/4 x 3/4 | 42.2 | 26.7 | 51 |

| 1 1/4 x 1/2 | 42.2 | 21.3 | 51 |

| 1 1/2 x 1 1/2 | 48.3 | 42.2 | 64 |

| 1 1/2 x 1 | 48.3 | 33.4 | 64 |

| 1 1/2 x 3/4 | 48.3 | 26.7 | 64 |

| 1 1/2 x 1/2 | 48.3 | 21.3 | 64 |

| 2 x 1 1/2 | 60.3 | 48.2 | 76 |

| 2 x 1 1/4 | 60.3 | 42.2 | 76 |

| 2 x 1 | 60.3 | 33.4 | 76 |

| 2 x 3/4 | 60.3 | 26.7 | 76 |

| 2 1/2 x 2 | 73 | 60.3 | 89 |

| 2 1/2 x 1 1/2 | 73 | 48.3 | 89 |

| 2 1/2 x 1 1/4 | 73 | 42.2 | 89 |

| 2 1/2 x 1 | 73 | 33.4 | 89 |

| 3 x 2 1/2 | 88.9 | 73 | 89 |

| 3 x 2 | 88.9 | 60.3 | 89 |

| 3 x 1 1/2 | 88.9 | 48.3 | 89 |

| 3 x 1 1/4 | 88.9 | 42.2 | 89 |

| 3 1/2 x 3 | 101.6 | 88.9 | 102 |

| 3 1/2 x 21/2 | 101.6 | 73 | 102 |

| 3 1/2 x 2 | 101.6 | 60.3 | 102 |

| 3 1/2 x 1 1/2 | 101.6 | 48.3 | 102 |

| 3 1/2 x 1 1/4 | 101.6 | 42.2 | 102 |

| 4 x 3 1/2 | 114.3 | 101.6 | 102 |

| 4 x 3 | 114.3 | 88.9 | 102 |

| 4 x 2 1/2 | 114.3 | 73 | 102 |

| 4 x 2 | 114.3 | 60.3 | 102 |

| 4 x 1 1/2 | 114.3 | 48.3 | 102 |

| 5 x 4 | 141.3 | 114.3 | 127 |

| 5 x 3 1/2 | 141.3 | 101.6 | 127 |

| 5 x 3 | 141.3 | 88.9 | 127 |

| 5 x 2 1/2 | 141.3 | 73 | 127 |

| 5 x 2 | 141.3 | 60.3 | 127 |

| 6 x 5 | 168.3 | 141.3 | 140 |

| 6 x 4 | 168.3 | 114.3 | 140 |

| 6 x 3 1/2 | 168.3 | 101.6 | 140 |

| 6 x 3 | 168.3 | 88.9 | 140 |

| 6 x 2 1/2 | 168.3 | 73 | 140 |

| 8 x 6 | 219.1 | 168.3 | 152 |

| 8 x 5 | 219.1 | 141.3 | 152 |

| 8 x 4 | 219.1 | 114.3 | 152 |

| 8 x 3 1/2 | 219.1 | 101.6 | 152 |

| 10 x 8 | 273.1 | 219.1 | 178 |

| 10 x 6 | 273.1 | 168.1 | 178 |

| 10 x 5 | 273.1 | 141.3 | 178 |

| 10 x 4 | 273.1 | 114.3 | 178 |

| 12 x 10 | 323.9 | 273.1 | 203 |

| 12 x 8 | 323.9 | 219.1 | 203 |

| 12 x 6 | 323.9 | 168.3 | 203 |

| 12 x 5 | 323.9 | 141.3 | 203 |

| 14 x 12 | 355.6 | 323.9 | 330 |

| 14 x 10 | 355.6 | 273.1 | 330 |

| 14 x 8 | 355.6 | 219.1 | 330 |

| 14 x 6 | 355.6 | 168.3 | 330 |

| 16 x 14 | 406.4 | 355.6 | 356 |

| 16 x 12 | 406.4 | 323.9 | 356 |

| 16 x 10 | 406.4 | 273.1 | 356 |

| 16 x 8 | 406.4 | 219.1 | 356 |

| 16 x 6 | 406.4 | 168.3 | 356 |

| 18 x 16 | 457 | 406.4 | 381 |

| 18 x 14 | 457 | 355.6 | 381 |

| 18 x 12 | 457 | 323.9 | 381 |

| 18 x 10 | 457 | 273.1 | 381 |

| 18 x 8 | 457 | 219.1 | 381 |

| 20 x 18 | 508 | 457 | 508 |

| 20 x 16 | 508 | 406.4 | 508 |

| 20 x 14 | 508 | 355.6 | 508 |

| 20 x 12 | 508 | 323.9 | 508 |

| 20 x 10 | 508 | 273.1 | 508 |

| 20 x 8 | 508 | 219.1 | 508 |

| 22 x 20 | 559 | 508 | 508 |

| 22 x 18 | 559 | 457 | 508 |

| 22 x 16 | 559 | 406.4 | 508 |

| 22 x 14 | 559 | 355.6 | 508 |

| 22 x 12 | 559 | 323.9 | 508 |

| 24 x 10 | 559 | 273.1 | 508 |

| 24 x 22 | 610 | 559 | 508 |

| 24 x 20 | 610 | 508 | 508 |

| 24 x 18 | 610 | 457 | 508 |

| 24 x 16 | 610 | 406.4 | 508 |

| 24 x 14 | 610 | 355.6 | 508 |

| 24 x 12 | 610 | 323.9 | 508 |

| 24 x 10 | 610 | 273.1 | 508 |

Manufacturing Process

The production of ASTM A234 WPB reducers involves the following processes:

- Material Selection: High-quality carbon steel conforming to ASTM A234 standards is used.

- Forming: The raw material is shaped into the desired reducer configuration through hot or cold forming processes.

- Heat Treatment: The formed reducer undergoes heat treatment to achieve desired mechanical properties, such as strength and ductility.

- Machining and Finishing: The reducer is machined to meet precise dimensional tolerances and surface finish requirements.

- Inspection and Testing: Comprehensive testing, including nondestructive tests, ensures the reducer meets ASTM specifications.

Advantages

- High Strength: Capable of withstanding high-pressure and high-temperature conditions.

- Corrosion Resistance: Exhibits excellent resistance to rust and chemical attacks.

- Versatility: Available in various configurations (concentric and eccentric) to meet diverse application needs.

- Ease of Installation: Compatible with various piping systems and welding processes.

- Cost-Effective: Offers long-term reliability and minimal maintenance requirements.

Testing Requirements

ASTM A234 WPB reducers undergo rigorous testing to ensure quality and performance:

- Tensile Testing: Verifies tensile and yield strength.

- Hardness Testing: Assesses material hardness.

- Impact Testing: Ensures durability under low-temperature conditions.

- Non-Destructive Testing (NDT): Includes ultrasonic and radiographic testing to detect internal defects.

- Dimensional Inspection: Ensures compliance with dimensional standards.

Applications

- Oil and Gas: Used in pipelines for crude oil, natural gas, and refined products.

- Petrochemical Plants: Suitable for handling chemicals and hydrocarbons.

- Power Plants: Essential for high-pressure steam lines and cooling systems.

- Water Treatment: Applied in desalination and sewage treatment plants.

- General Industries: Used in HVAC, firefighting, and plumbing systems.

Reviews

There are no reviews yet.