ASTM A234 WPB Tee

ASTM A234 WPB Tee is a crucial component in pipeline systems, used extensively in industries such as petrochemical, oil and gas, power generation, and chemical processing. These fittings are designed to handle high-pressure and high-temperature environments, making them suitable for a wide range of industrial applications. ASTM A234 WPB Tee is a type of pipe fitting that allows the branching of a pipeline system into two or more directions. The “Tee” shape includes one inlet and two outlets (or vice versa), which can be of the same or varying diameters. The WPB designation stands for:

- W: Weldable

- P: Pressure-grade

- B: Grade B material, typically carbon steel

Key Features

- Material: High-grade carbon steel (Grade B).

- Pressure Handling: Designed to withstand high-pressure environments.

- Temperature Resistance: Suitable for both moderate and high-temperature applications.

- Corrosion Resistance: Can be enhanced with additional coatings or galvanization.

- Versatility: Available in various sizes, wall thicknesses, and configurations.

- Durability: Manufactured to endure mechanical stresses and harsh conditions.

ASTM A234 WPB Dimensions

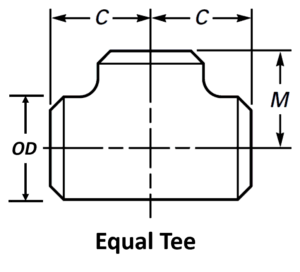

ASTM A234 WPB Straight / Equal Tee Dimensions

| NOMINAL PIPE SIZE | OUTSIDE DIAMETER | CENTER TO END | LENGTH |

| Inch. | OD | C | M |

| 1/2 | 21.3 | 25 | 25 |

| 3/4 | 26.7 | 29 | 29 |

| 1 | 33.4 | 38 | 38 |

| 1 1/4 | 42.2 | 48 | 48 |

| 1 1/2 | 48.3 | 57 | 57 |

| 2 | 60.3 | 64 | 64 |

| 2 1/2 | 73 | 76 | 76 |

| 3 | 88.9 | 86 | 86 |

| 3 1/2 | 101.6 | 95 | 95 |

| 4 | 114.3 | 105 | 105 |

| 5 | 141.3 | 124 | 124 |

| 6 | 168.3 | 143 | 143 |

| 8 | 219.1 | 178 | 178 |

| 10 | 273.1 | 216 | 216 |

| 12 | 323.9 | 254 | 254 |

| 14 | 355.6 | 279 | 279 |

| 16 | 406.4 | 305 | 305 |

| 18 | 457.2 | 343 | 343 |

| 20 | 508 | 381 | 381 |

| 22 | 559 | 419 | 419 |

| 24 | 610 | 432 | 432 |

| 26 | 660 | 495 | 495 |

| 28 | 711 | 521 | 521 |

| 30 | 762 | 559 | 559 |

| 32 | 813 | 597 | 597 |

| 34 | 864 | 635 | 635 |

| 36 | 914 | 673 | 673 |

| 38 | 965 | 711 | 711 |

| 40 | 1016 | 749 | 749 |

| 42 | 1067 | 762 | 711 |

| 44 | 1118 | 813 | 762 |

| 46 | 1168 | 851 | 800 |

| 48 | 1219 | 889 | 838 |

ASTM A234 WPB Reducing Tee Dimensions

| NOMINAL PIPE SIZE | OUTSIDE DIAMETER | CENTER TO END | ||

| Inch | D | P | C | M |

| 1/2 x 3/8 | 21.3 | 17.1 | 25 | 25 |

| 1/2 x 1/4 | 21.3 | 13.7 | 25 | 25 |

| 3/4 x 1/2 | 26.7 | 21.3 | 29 | 29 |

| 3/4 x 3/8 | 26.7 | 17.1 | 29 | 29 |

| 1 x 3/4 | 33.4 | 26.7 | 38 | 38 |

| 1 x 1/2 | 33.4 | 21.3 | 38 | 38 |

| 1 1/4 x 1 | 42.2 | 33.4 | 48 | 48 |

| 1 1/4 x 3/4 | 42.2 | 26.7 | 48 | 48 |

| 1 1/4 x 1/2 | 42.2 | 21.3 | 48 | 48 |

| 1 1/2 x 1 1/2 | 48.3 | 42.2 | 57 | 57 |

| 1 1/2 x 1 | 48.3 | 33.4 | 57 | 57 |

| 1 1/2 x 3/4 | 48.3 | 26.7 | 57 | 57 |

| 1 1/2 x 1/2 | 48.3 | 21.3 | 57 | 57 |

| 2 x 1 1/2 | 60.3 | 48.2 | 64 | 60 |

| 2 x 1 1/4 | 60.3 | 42.2 | 64 | 57 |

| 2 x 1 | 60.3 | 33.4 | 64 | 51 |

| 2 x 3/4 | 60.3 | 26.7 | 64 | 44 |

| 2 1/2 x 2 | 73 | 60.3 | 76 | 70 |

| 2 1/2 x 1 1/2 | 73 | 48.3 | 76 | 67 |

| 2 1/2 x 1 1/4 | 73 | 42.2 | 76 | 64 |

| 2 1/2 x 1 | 73 | 33.4 | 76 | 57 |

| 3 x 2 1/2 | 88.9 | 73 | 86 | 83 |

| 3 x 2 | 88.9 | 60.3 | 86 | 76 |

| 3 x 1 1/2 | 88.9 | 48.3 | 86 | 73 |

| 3 x 1 1/4 | 88.9 | 42.2 | 86 | 70 |

| 3 1/2 x 3 | 101.6 | 88.9 | 95 | 92 |

| 3 1/2 x 21/2 | 101.6 | 73 | 95 | 89 |

| 3 1/2 x 2 | 101.6 | 60.3 | 95 | 83 |

| 3 1/2 x 1 1/2 | 101.6 | 48.3 | 95 | 79 |

| 4 x 3 1/2 | 114.3 | 101.6 | 105 | 102 |

| 4 x 3 | 114.3 | 88.9 | 105 | 98 |

| 4 x 2 1/2 | 114.3 | 73 | 105 | 95 |

| 4 x 2 | 114.3 | 60.3 | 105 | 89 |

| 4 x 1 1/2 | 114.3 | 48.3 | 105 | 86 |

| 5 x 4 | 141.3 | 114.3 | 124 | 117 |

| 5 x 3 1/2 | 141.3 | 101.6 | 124 | 114 |

| 5 x 3 | 141.3 | 88.9 | 124 | 111 |

| 5 x 2 1/2 | 141.3 | 73 | 124 | 108 |

| 5 x 2 | 141.3 | 60.3 | 124 | 105 |

| 6 x 5 | 168.3 | 141.3 | 143 | 137 |

| 6 x 4 | 168.3 | 114.3 | 143 | 130 |

| 6 x 3 1/2 | 168.3 | 101.6 | 143 | 127 |

| 6 x 3 | 168.3 | 88.9 | 143 | 124 |

| 6 x 2 1/2 | 168.3 | 73 | 143 | 121 |

| 8 x 6 | 219.1 | 168.3 | 178 | 168 |

| 8 x 5 | 219.1 | 141.3 | 178 | 162 |

| 8 x 4 | 219.1 | 114.3 | 178 | 156 |

| 8 x 3 1/2 | 219.1 | 101.6 | 178 | 152 |

| 10 x 8 | 273.1 | 219.1 | 216 | 203 |

| 10 x 6 | 273.1 | 168.1 | 216 | 194 |

| 10 x 5 | 273.1 | 141.3 | 216 | 191 |

| 10 x 4 | 273.1 | 114.3 | 216 | 184 |

| 12 x 10 | 323.9 | 273.1 | 254 | 241 |

| 12 x 8 | 323.9 | 219.1 | 254 | 229 |

| 12 x 6 | 323.9 | 168.3 | 254 | 219 |

| 12 x 5 | 323.9 | 141.3 | 254 | 216 |

| 14 x 12 | 355.6 | 323.9 | 279 | 270 |

| 14 x 10 | 355.6 | 273.1 | 279 | 257 |

| 14 x 8 | 355.6 | 219.1 | 279 | 248 |

| 14 x 6 | 355.6 | 168.3 | 279 | 238 |

| 16 x 14 | 406.4 | 355.6 | 305 | 305 |

| 16 x 12 | 406.4 | 323.9 | 305 | 295 |

| 16 x 10 | 406.4 | 273.1 | 305 | 283 |

| 16 x 8 | 406.4 | 219.1 | 305 | 273 |

| 16 x 6 | 406.4 | 168.3 | 305 | 264 |

| 18 x 16 | 457 | 406.4 | 343 | 330 |

| 18 x 14 | 457 | 355.6 | 343 | 330 |

| 18 x 12 | 457 | 323.9 | 343 | 321 |

| 18 x 10 | 457 | 273.1 | 343 | 308 |

| 18 x 8 | 457 | 219.1 | 343 | 298 |

| 20 x 18 | 508 | 457 | 381 | 368 |

| 20 x 16 | 508 | 406.4 | 381 | 356 |

| 20 x 14 | 508 | 355.6 | 381 | 356 |

| 20 x 12 | 508 | 323.9 | 381 | 346 |

| 20 x 10 | 508 | 273.1 | 381 | 333 |

| 20 x 8 | 508 | 219.1 | 381 | 324 |

| 22 x 20 | 559 | 508 | 419 | 406 |

| 22 x 18 | 559 | 457 | 419 | 394 |

| 22 x 16 | 559 | 406.4 | 419 | 381 |

| 22 x 14 | 559 | 355.6 | 419 | 381 |

| 22 x 12 | 559 | 323.9 | 419 | 371 |

| 24 x 10 | 559 | 273.1 | 419 | 359 |

| 24 x 22 | 610 | 559 | 432 | 432 |

| 24 x 20 | 610 | 508 | 432 | 432 |

| 24 x 18 | 610 | 457 | 432 | 419 |

| 24 x 16 | 610 | 406.4 | 432 | 406 |

| 24 x 14 | 610 | 355.6 | 432 | 406 |

| 24 x 12 | 610 | 323.9 | 432 | 397 |

| 24 x 10 | 610 | 273.1 | 432 | 384 |

Pipe Fitting Tolerance

| NOMINAL PIPE SIZE | ALL FITTINGS | ALL FITTINGS | ALL FITTINGS | ELBOWS AND TEES | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | REDUCERS | CAPS |

| NPS | O.D. at Bevel (1), (2) | I.D. at End | Wall Thickness (3) | Centre-to-End Dimension A,B,C,M | Centre-to-Centre O | Back-to-Face K | Alignment of Ends U | Overall Length H | Overall Length E |

| (1), (3), (4) | |||||||||

| ½ to 2½ | 0.06 | 0.03 | Not less than 87.5% of nominal thickness | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| -0.03 | |||||||||

| 3 to 3 ½ | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 4 | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 5 to 8 | 0.09 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 | |

| -0.06 | |||||||||

| 10 to 18 | 0.16 | 0.12 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| -0.12 | |||||||||

| 20 to 24 | 0.25 | 0.19 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| -0.19 | |||||||||

| 26 to 30 | 0.25 | 0.19 | 0.12 | … | … | … | 0.19 | 0.38 | |

| -0.19 | |||||||||

| 32 to 48 | 0.25 | 0.19 | 0.19 | … | … | … | 0.19 | 0.38 | |

| -0.19 |

| NOMINAL PIPE SIZE NPS | ANGULARITY TOLERANCES | ANGULARITY TOLERANCES |

| Off Angle Q | Off Plane P | |

| ½ to 4 | 0.03 | 0.06 |

| 5 to 8 | 0.06 | 0.12 |

| 10 to 12 | 0.09 | 0.19 |

| 14 to 16 | 0.09 | 0.25 |

| 18 to 24 | 0.12 | 0.38 |

| 26 to 30 | 0.19 | 0.38 |

| 32 to 42 | 0.19 | 0.5 |

| 44 to 48 | 0.18 | 0.75 |

Types of ASTM A234 WPB Tee

- Equal Tee:

- Reducing Tee:

Manufacturing Process

ASTM A234 WPB Tees are manufactured through several standardized processes to ensure durability and precision:

-

- Raw Material Selection: High-quality carbon steel is chosen as the base material, adhering to the chemical composition specified in ASTM A234.

- Forging: The material is heated and shaped under high pressure to achieve the desired dimensions and structural integrity.

- Forming: Hot or cold forming methods are used to create the “Tee” shape.

- Heat Treatment:

-

- Normalizing or annealing processes are applied to enhance material properties like strength, ductility, and toughness.

- Inspection and Testing: The finished products undergo rigorous quality checks, including visual inspection, dimensional analysis, and non-destructive testing (NDT).

- Marking and Certification: Each fitting is marked with details such as size, material grade, and specification to ensure traceability.

Testing and Quality Control

To ensure reliability, ASTM A234 WPB Tees are subjected to stringent testing protocols:

- Hydrostatic Testing: Verifies the fitting’s ability to withstand internal pressure without leakage.

- Radiographic Testing (RT): Identifies internal defects or inclusions.

- Magnetic Particle Inspection (MPI): Detects surface and near-surface flaws.

- Ultrasonic Testing (UT): Ensures internal soundness.

- Chemical Analysis: Confirms adherence to specified chemical composition.

- Mechanical Testing: Includes tensile, hardness, and impact tests.

Applications

The versatility and robustness of ASTM A234 WPB Tee make it suitable for diverse applications, including:

- Oil and Gas Industry: Used in pipelines for transporting crude oil and natural gas.

- Petrochemical Plants: Facilitates the distribution of chemicals and by-products.

- Power Plants: Suitable for high-pressure steam and water lines.

- Water Treatment Facilities: Ensures efficient flow control and distribution.

- Shipbuilding: Used in fuel and hydraulic systems.

- Construction: Integral to HVAC systems and fire-fighting pipelines.

Advantages

- High Durability: Built to last in extreme conditions.

- Pressure and Temperature Resilience: Performs efficiently in challenging environments.

- Ease of Fabrication: Can be welded and machined easily.

- Cost-Effective: Combines affordability with performance.

Conclusion

ASTM A234 WPB Tee is an indispensable fitting in pipeline systems, offering unmatched reliability, durability, and performance. Its ability to withstand high pressures and temperatures makes it a preferred choice for industries worldwide. By adhering to strict manufacturing standards and rigorous quality checks, these tees ensure seamless operation and long-lasting service in demanding environments. Whether used in the oil and gas sector, power plants, or construction projects, ASTM A234 WPB Tee remains a benchmark of quality and efficiency in piping solutions.

Reviews

There are no reviews yet.