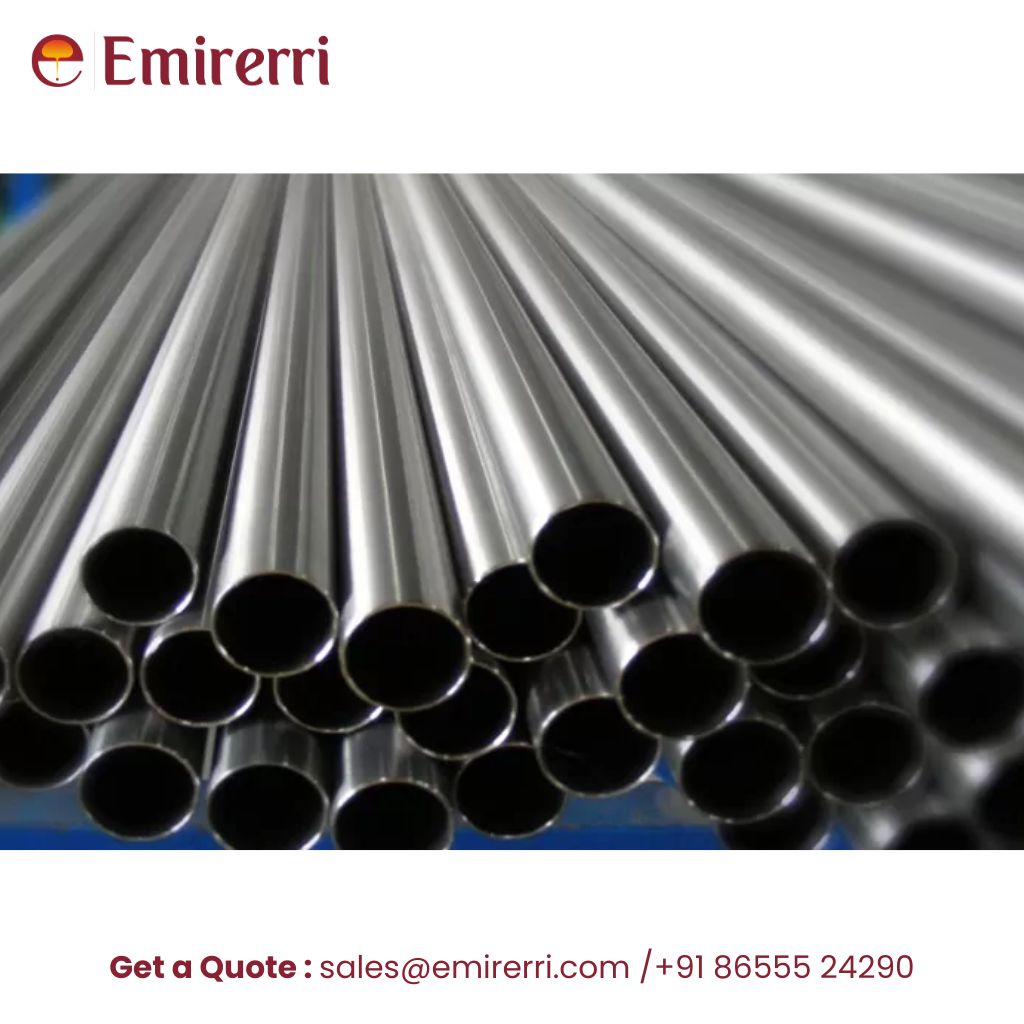

ASTM B167 UNS N06600 (Inconel 600) Pipe

ASTM B167 UNS N06600 specifies seamless and welded pipes manufactured from high-performance nickel-chromium alloy Inconel 600. Known for its outstanding strength, oxidation resistance, and stability across elevated temperatures, Alloy 600 is widely used in chemical processing, heat-treatment systems, nuclear engineering, and furnace components. Its excellent resistance to chloride-ion stress corrosion cracking, carburization, and high-temperature oxidation makes it ideal for aggressive and thermal-cycling environments.

Key Features

- High temperature strength and oxidation resistance

- Excellent resistance to chloride stress corrosion cracking

- Non-magnetic with superior mechanical stability

- Good performance in carburizing and nitriding atmospheres

- Suitable for cryogenic to high-temperature applications

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | N06600 |

| Werkstoff Nr. | 2.4816 |

| AFNOR | NC15FE |

| BS | NA14 |

Available Sizes

- Outer Diameter: 1/8″ NPS (0.405″ OD) to 48″ NPS

- Wall Thickness: 0.3 mm to 50 mm+ (Schedules 5, 10, 40, 80, 160, XXS)

- Tube OD Range: 3 mm to 600 mm

- Length: SRL, DRL, Custom Cut Lengths

ASTM B167 UNS N06600 Chemical Composition

| Element | % |

|---|---|

| Nickel (Ni) | 72.0 min |

| Chromium (Cr) | 14.0 – 17.0 |

| Iron (Fe) | 6.0 – 10.0 |

| Carbon (C) | 0.15 max |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 0.5 max |

| Sulfur (S) | 0.015 max |

UNS N06600 Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 550 MPa min |

| Yield Strength (0.2% offset) | 240 MPa min |

| Elongation | 30% min |

ASTM B167 Inconel 600 Physical Properties

| Property | Value |

|---|---|

| Density | 8.47 g/cm³ |

| Melting Range | 1354°C – 1413°C |

| Electrical Resistivity | 1.03 µΩ·m |

| Thermal Conductivity | 14.8 W/m·K |

Type of ASTM B167 UNS N06600 Pipes

- Inconel 600 Seamless Pipes

- Inconel 600 Welded Pipes

- Round / Square / Hydraulic Tubes

- Annealed & Straight Length Pipes

- Heat Exchanger & Condenser Tubes

Applications

- Chemical processing & acid production systems

- Heat treatment and furnace components

- Nuclear reactor and steam generator tubing

- Aerospace and thermal applications

- Petrochemical heaters and reformer units

- Cryogenic equipment

Reviews

There are no reviews yet.