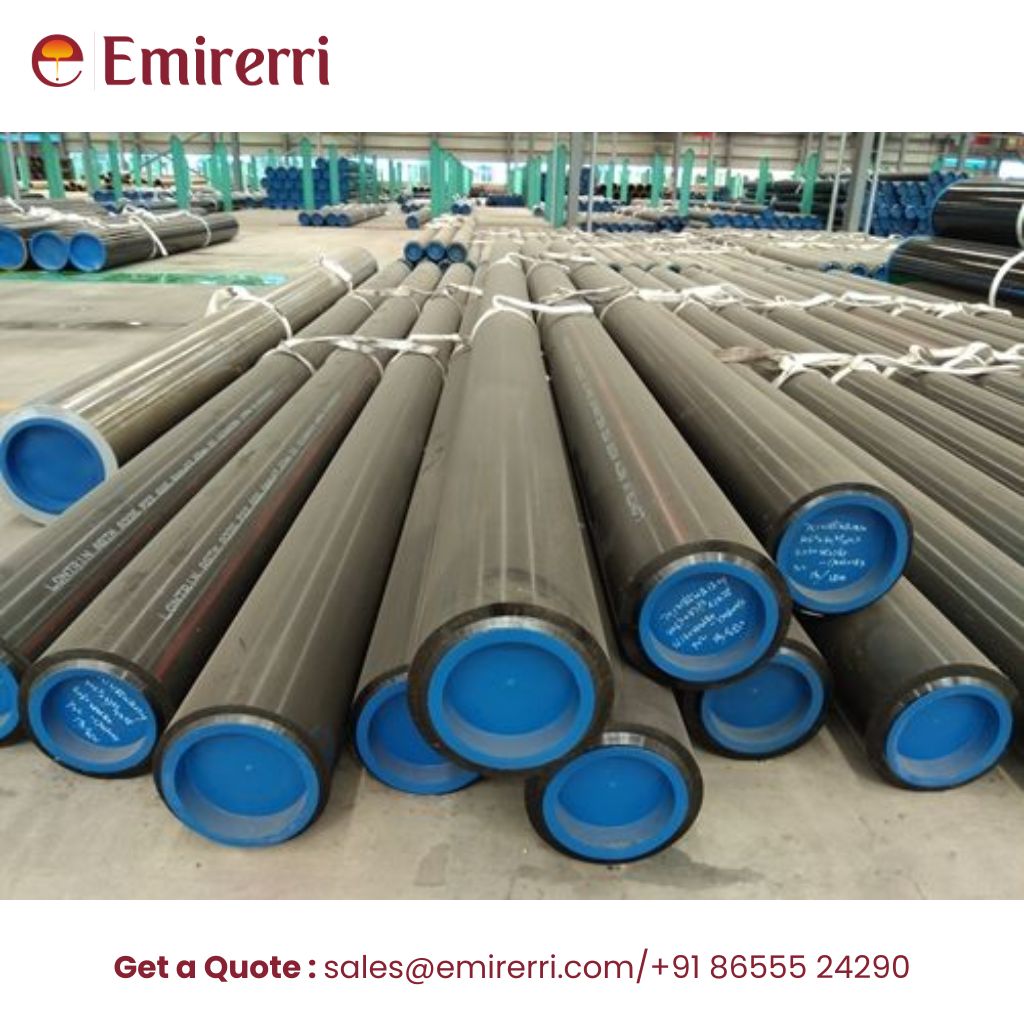

Seamless Carbon Steel Tube

Seamless Carbon Steel Tube Manufacturer & Supplier

Emirerri Steel is a globally recognized supplier and exporter of Seamless Carbon Steel Tubes, catering to diverse industries with high-performance tubular solutions. Known for their strength, durability, and versatility, seamless carbon steel tubes are the backbone of applications that demand resistance to pressure, mechanical stress, and temperature fluctuations.

At Emirerri Steel, we manufacture seamless carbon steel tubes that meet stringent ASTM, ASME, DIN, EN, and ISO standards, ensuring reliability and consistency in every product. With decades of expertise, advanced production facilities, and a customer-first approach, we have earned the trust of clients worldwide.

What is a Seamless Carbon Steel Tube?

A seamless carbon steel tube is a tubular product manufactured without a welded seam. It is created by piercing solid steel billets and rolling them into a hollow structure. Unlike welded tubes, seamless tubes have a uniform structure and no weak points, making them ideal for high-pressure and high-temperature applications.

Key Features:

High Strength: Capable of withstanding extreme pressure and load.

Uniform Structure: No seam or weld joint ensures reliability.

Versatility: Used in various industries, from oil & gas to construction.

Cost-Effective: Durable and long-lasting with minimal maintenance.

Carbon Steel Pipes & Tubes

ASTM A106 / SA106

ASTM A53 / SA53

ASTM A179 / SA179

ASTM A192 / SA192

ASTM A210 / SA210

ASTM A333 / SA333

ASTM A500

ASTM A519

API Pipes

Manufacturing Process

Billet Selection: High-quality carbon steel billets sourced from trusted mills.

Heating & Piercing: Billets are heated and pierced to form hollow shells.

Hot Rolling: The pierced billet is elongated and rolled into tubular form.

Cold Drawing (if required): Achieves precise dimensions and smoother finish.

Heat Treatment: Enhances toughness, hardness, and mechanical properties.

Pickling & Surface Finishing: Removes scale and ensures a clean finish.

Inspection & Testing: Every tube undergoes dimensional and quality checks.

Applications

Oil & Gas Industry – Pipelines, refinery equipment, offshore platforms.

Power Generation – Boilers, heat exchangers, condensers.

Automotive & Mechanical Engineering – Shock absorbers, axles, and precision parts.

Construction & Infrastructure – Structural supports, scaffolding, bridges.

Shipbuilding & Marine – Hydraulic systems, pipelines, pressure vessels.

Petrochemical & Chemical Industry – Handling fluids under high pressure.