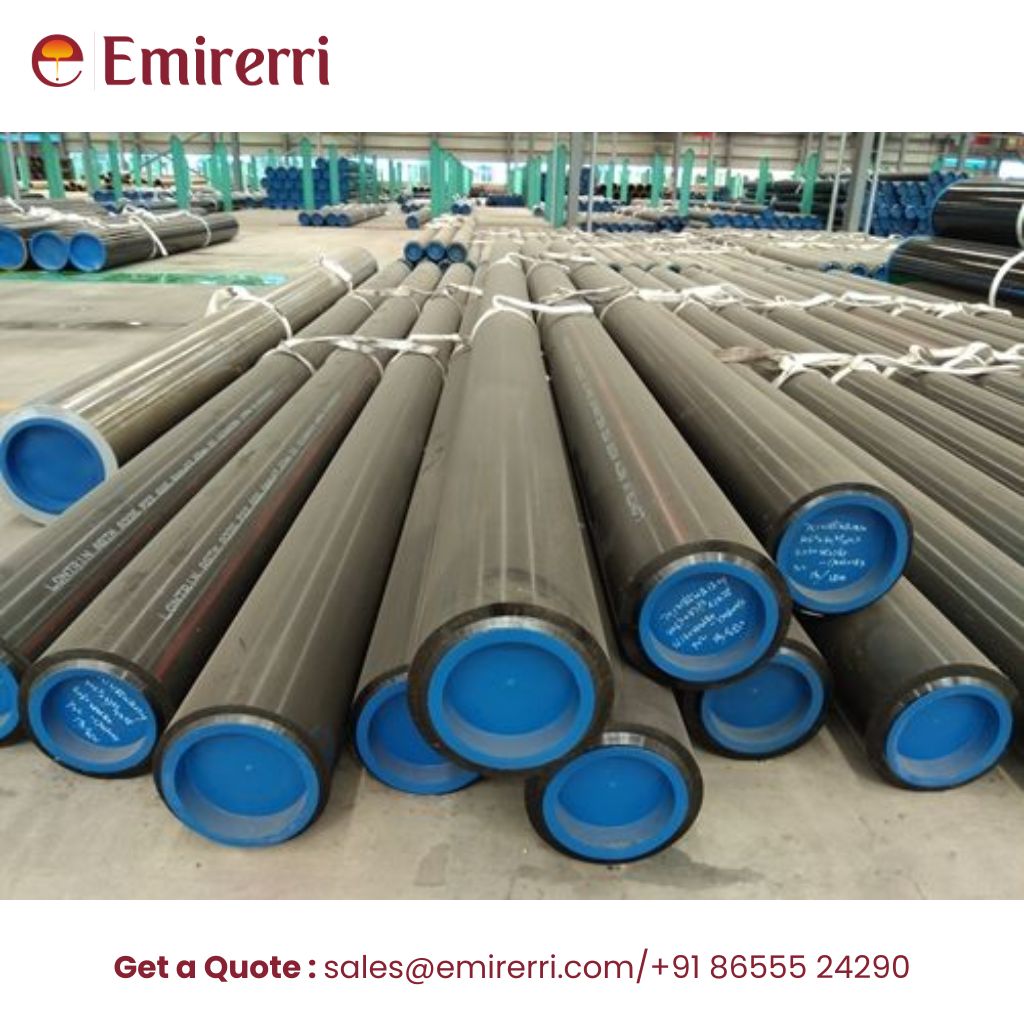

Seamless Steel Tube

Seamless Steel Tube Supplier & Manufacturer

Emirerri Steel is a trusted name in the steel industry, delivering superior quality steel products to customers worldwide. Among our comprehensive product portfolio, Seamless Steel Tubes stand out as one of the most demanded solutions for critical applications across industries. Known for their strength, precision, durability, and resistance to pressure, seamless tubes form the backbone of modern engineering, oil & gas exploration, energy, automotive, and construction sectors.

At Emirerri Steel, we specialize in manufacturing and supplying premium-grade seamless steel tubes that conform to international standards. With advanced production facilities and rigorous quality control, our seamless tubes meet the most challenging operational requirements, ensuring long-lasting performance and safety.

What is a Seamless Steel Tube?

A seamless steel tube is a cylindrical hollow section manufactured without any welding seam or joint. Unlike welded tubes, which are produced by rolling and welding steel strips, seamless tubes are made from a solid round steel billet that is heated and pierced through the center to create a hollow shell. This process provides:

Uniform structure and strength across the tube

High resistance to pressure and stress

Leak-proof performance, crucial for fluid and gas transport

Enhanced corrosion and heat resistance

Because of these qualities, seamless tubes are widely preferred for high-pressure, high-temperature, and critical applications.

Standards & Specifications

Carbon Steel Seamless Tubing – Grades by Standard

ASTM / ASME

ASTM A106 / SA106 → Grades A, B, C

ASTM A53 / SA53 → Grades A, B

ASTM A179 / SA179 → Low-Carbon Steel (single grade, no subdivisions)

ASTM A192 / SA192 → High-Pressure Carbon Steel (single grade)

ASTM A210 / SA210 → Grades A-1, C

ASTM A333 / SA333 → Grades 1, 3, 4, 6, 7, 8, 9, 10, 11 (low-temperature service)

ASTM A500 → Grades A, B, C, D (structural tubing)

ASTM A513 → Various grades depending on type (e.g., 1010, 1020, 1026)

ASTM A519 → Grades like 1010, 1020, 1026, 4130, 4140

API (Oil & Gas)

API 5L → Grades A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80

API 5CT → Grades H40, J55, K55, N80, L80, C90, T95, P110, Q125

EN / DIN

EN 10216-1 → Grades P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2

EN 10216-2 → Grades P235GH, P265GH, 16Mo3, 13CrMo4-5, 10CrMo9-10

DIN 1629 → Grades St 37.0, St 44.0, St 52.0

DIN 17175 → Grades St35.8, St45.8, 15Mo3, 13CrMo44

BS (British Standards)

BS 3059 Part 1 → Grades 320, 360

BS 3059 Part 2 → Grades 243, 360, 440

BS 3602 → Grades like 360, 410 (for pressure purposes)

JIS (Japanese Standards)

JIS G3454 → Grades STPG 370, STPG 410

JIS G3455 → Grades STS 370, STS 410

JIS G3456 → Grades STPT 370, STPT 410, STPT 480

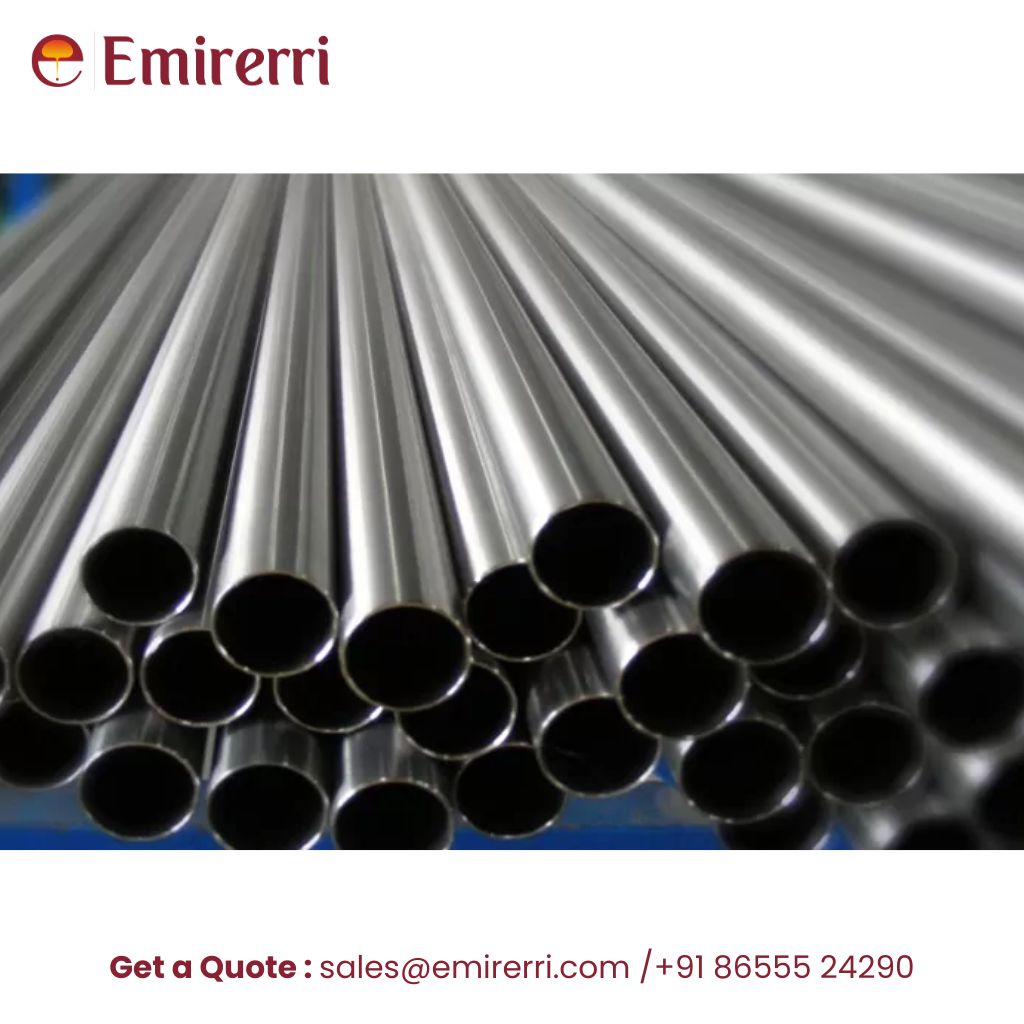

Stainless Steel Seamless Tubing Standards & Grades

ASTM / ASME (American Standards)

ASTM A213 / ASME SA213 → Seamless Austenitic & Ferritic Stainless Steel Tubes for Boilers, Superheaters & Heat Exchangers

Grades: TP304, TP304H, TP304L, TP316, TP316H, TP316L, TP317, TP321, TP321H, TP347, TP347H, TP310S, TP904L

ASTM A269 / ASME SA269 → Seamless & Welded Austenitic Stainless Steel Tubes for General Service

Grades: TP304, TP304L, TP316, TP316L, TP321, TP347

ASTM A312 / ASME SA312 → Seamless Austenitic Stainless Steel Pipes (often used for larger-diameter tubing as well)

Grades: TP304, TP304L, TP316, TP316L, TP321, TP347, TP310S, TP904L, Duplex Grades

ASTM A249 / ASME SA249 → Welded Austenitic Stainless Steel Tubes (but also often referenced alongside seamless for interchange)

ASTM A269 / A213 → Cold-Drawn Seamless Tubes for High Precision Applications

EN / DIN (European Standards)

EN 10216-5 → Seamless Stainless Steel Tubes for Pressure Purposes

Grades: 1.4301 (304), 1.4306 (304L), 1.4541 (321), 1.4401 (316), 1.4404 (316L), 1.4571 (316Ti), 1.4438 (317L), 1.4539 (904L)

DIN 17456 / 17458 → Seamless Austenitic Stainless Steel Tubes for General & Pressure Service

Grades: X5CrNi18-10 (304), X2CrNi19-11 (304L), X5CrNiMo17-12-2 (316), X2CrNiMo17-12-2 (316L), X6CrNiTi18-10 (321), X6CrNiNb18-10 (347)

BS (British Standards)

BS EN 10216-5 (aligned with EN) – Seamless Stainless Steel Tubes for Pressure

BS 3605 → Austenitic Stainless Steel Pipes & Tubes for Pressure & General Purposes

Grades: 304, 304L, 316, 316L, 321, 347

JIS (Japanese Standards)

JIS G3459 → Stainless Steel Pipes for General Service

Grades: SUS304, SUS304L, SUS316, SUS316L, SUS321, SUS347

JIS G3463 → Stainless Steel Boiler & Heat Exchanger Tubes

Grades: SUS304, SUS304L, SUS316, SUS316L, SUS321, SUS347, SUS310S

Special Grades (High Performance)

Duplex & Super Duplex Stainless Steel → UNS S31803 (2205), S32205, S32750, S32760

Nickel Alloys / Special Grades (sometimes classified alongside stainless seamless tubing) → Alloy 20, 904L, Hastelloy grades

Alloy Steel Seamless Tubing – Standards & Grades

ASTM / ASME (American Standards)

ASTM A213 / ASME SA213 – Seamless Ferritic & Austenitic Alloy Steel Tubes for Boilers, Superheaters, and Heat Exchangers

Grades: T2, T5, T9, T11, T12, T22, T23, T24, T91, T92, T122, T911

ASTM A335 / ASME SA335 – Seamless Ferritic Alloy Steel Pipes (often supplied as tubing for high-temperature service)

Grades: P1, P2, P5, P9, P11, P12, P22, P23, P24, P91, P92, P122, P911

ASTM A209 / ASME SA209 – Seamless Carbon-Molybdenum Alloy Steel Boiler & Superheater Tubes

Grades: T1, T1a, T1b

ASTM A369 / ASME SA369 – Seamless Ferritic Alloy Steel Pipe for High-Temperature Service

Grades: FW, FP1, FP2, FP5, FP9, FP11, FP12, FP22, FP91

EN / DIN (European Standards)

EN 10216-2 – Seamless Tubes for Pressure Purposes, Non-Alloy & Alloy Steels with Specified Elevated Temperature Properties

Grades: 10CrMo9-10, 13CrMo4-5, 14MoV6-3, X11CrMo5, X10CrMoVNb9-1 (P91), X10CrWMoVNb9-2 (P92)

DIN 17175 – Seamless Tubes of Heat-Resistant Steels

Grades: 15Mo3, 13CrMo44, 10CrMo910, X20CrMoV121

BS (British Standards)

BS 3059 Part 2 – Alloy Steel Tubes for Boiler & Heat Exchanger Service

Grades: 360, 440 (with alloying elements)

BS 3604 – Alloy Steel Seamless Tubes for Pressure Purposes

Grades: Equivalent to ASTM P & T series

JIS (Japanese Standards)

JIS G3462 – Alloy Steel Tubes for Boiler and Heat Exchanger Service

Grades: STBA 12, STBA 20, STBA 22, STBA 23, STBA 24, STBA 25

JIS G3458 – Alloy Steel Pipes for High-Temperature Service

Grades: STS 370, STS 410, STS 480, STS 530 (with Cr-Mo alloy content)

Carbon Steel Pipes & Tubes

ASTM A106 / SA106

ASTM A53 / SA53

ASTM A179 / SA179

ASTM A192 / SA192

ASTM A210 / SA210

ASTM A333 / SA333

ASTM A500

ASTM A513

ASTM A519

Stainless Steel Pipes & Tubes

ASTM A213 / ASME SA213

ASTM A269 / ASME SA269

ASTM A312 / ASME SA312

ASTM A249 / ASME SA249

ASTM A554 / ASME SA554

Duplex & Super Duplex Steel

ASTM A789

ASTM A789

ASTM A790

Alloy Steel Pipes & Tubes

ASTM A213 / ASME SA213

ASTM A335 / ASME SA335

ASTM A209 / ASME SA209

ASTM A369 / ASME SA369

Nickel Alloy Pipes & Tubes

ASTM B161

ASTM B163

ASTM B165

ASTM B725

ASTM B167

ASTM B423

ASTM B622

ASTM B626

Titanium Pipes & Tubes

ASTM B338

ASTM B861

Copper Alloy Tubes

ASTM B88

ASTM B111

ASTM B466

Advantages of Seamless Steel Tubes

Superior Strength – Without weak points such as weld seams, seamless tubes can withstand higher pressures.

Excellent Dimensional Accuracy – Produced with precision, these tubes provide tight tolerances required in critical industries.

Corrosion Resistance – High-quality alloys and steel grades ensure resistance to rust, scaling, and chemical attack.

Versatility – Available in various grades, sizes, and finishes suitable for multiple industrial applications.

Cost Efficiency – Longer life span and reduced maintenance costs make seamless tubes a reliable investment.

Manufacturing Process of Seamless Steel Tube

Emirerri Steel follows advanced technology and strict quality checks at every stage of manufacturing seamless tubes:

Billet Preparation – Premium-grade steel billets are selected and heated to the required temperature.

Piercing – A rotary piercing process creates a hollow shell from the heated billet.

Elongation – The hollow shell is elongated using rolling mills to achieve desired dimensions.

Sizing & Finishing – Tubes are further processed for accuracy in thickness and diameter.

Heat Treatment – Enhances mechanical properties, toughness, and corrosion resistance.

Testing & Inspection – Non-destructive tests (NDT), hydrostatic tests, and visual inspections guarantee quality.

Applications of Seamless Steel Tubes

Seamless steel tubes are essential across numerous industries due to their reliability and ability to withstand extreme conditions:

Oil & Gas Industry – Used in drilling, casing, tubing, and pipeline transportation.

Power Generation – Boilers, heat exchangers, and superheater tubes.

Automobile Industry – Shock absorbers, drive shafts, and structural parts.

Petrochemical & Refineries – For transporting chemicals, gases, and fluids.

Construction & Infrastructure – Scaffolding, structural supports, and precision engineering.

Aerospace & Defense – High-performance applications requiring strength and reliability.

Export & Global Reach

Emirerri Steel is a recognized exporter of seamless steel tubes, supplying to clients in Tunisia, North Africa, Middle East, Europe, USA, South America, and Asia. We understand global market requirements and offer competitive pricing, timely delivery, and proper documentation for smooth transactions.

Our seamless tubes are trusted by leading EPC contractors, oil companies, power plants, and engineering firms worldwide.

Conclusion

Seamless Steel Tubes by Emirerri Steel are designed to deliver unmatched strength, durability, and performance across diverse industries. With our modern infrastructure, technical expertise, and commitment to excellence, we ensure that our clients receive world-class seamless tubes tailored to their needs.

Whether your requirement is for high-pressure boiler tubes, precision stainless steel tubing, or customized alloy tubes, Emirerri Steel is your reliable partner.