Stainless Steel Buttweld Reducer

Stainless Steel Buttweld Reducer Manufacturer & Supplier

What is a Stainless Steel Buttweld Reducer?

A stainless steel buttweld reducer is a pipe fitting used to connect two pipes of different diameters, either increasing (expander) or decreasing (reducer) the pipe size. It is joined to the pipes via butt welding, providing a permanent, strong, and leak-proof connection.

Unlike threaded or socket weld fittings, buttweld reducers can handle high-pressure, high-temperature, and corrosive environments, making them ideal for demanding industrial applications. They are manufactured according to international standards such as ASME B16.9, ASTM A403, and MSS-SP-43 and are available in various stainless steel grades like SS 304, SS 304L, SS 316, SS 316L, SS 321, SS 347, SS 904L, Duplex, and Super Duplex.

Types of Stainless Steel Buttweld Reducers

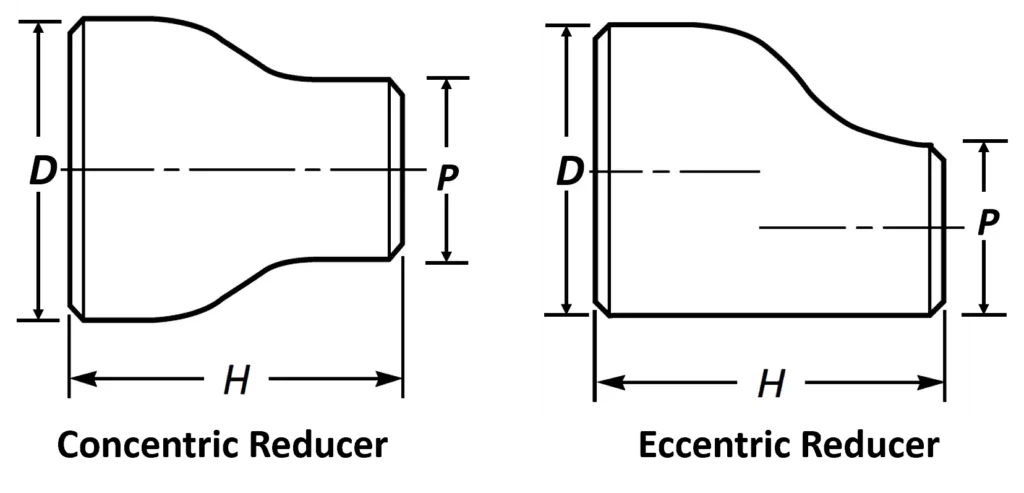

1. Concentric Reducer

A concentric reducer has a common centerline for both the larger and smaller pipe ends. It is used where the flow needs to remain uniform and is ideal for vertical or horizontal pipelines where no air accumulation is expected.

2. Eccentric Reducer

An eccentric reducer has an offset centerline, with the top or bottom of the pipe aligned to prevent air pockets or liquid accumulation. It is particularly useful in horizontal pipelines where drainage or venting is important.

Pipe Reducer Dimensions – Concentric and Eccentric Reducer Dimensions

| NOMINAL PIPE SIZE | OUTSIDE DIAMETER | END TO END | |

|---|---|---|---|

| Inch | D | P | H |

| 3/4 x 1/2 | 26.7 | 21.3 | 38 |

| 3/4 x 3/8 | 26.7 | 17.1 | 38 |

| 1 x 3/4 | 33.4 | 26.7 | 51 |

| 1 x 1/2 | 33.4 | 21.3 | 51 |

| 1 1/4 x 1 | 42.2 | 33.4 | 51 |

| 1 1/4 x 3/4 | 42.2 | 26.7 | 51 |

| 1 1/4 x 1/2 | 42.2 | 21.3 | 51 |

| 1 1/2 x 1 1/2 | 48.3 | 42.2 | 64 |

| 1 1/2 x 1 | 48.3 | 33.4 | 64 |

| 1 1/2 x 3/4 | 48.3 | 26.7 | 64 |

| 1 1/2 x 1/2 | 48.3 | 21.3 | 64 |

| 2 x 1 1/2 | 60.3 | 48.2 | 76 |

| 2 x 1 1/4 | 60.3 | 42.2 | 76 |

| 2 x 1 | 60.3 | 33.4 | 76 |

| 2 x 3/4 | 60.3 | 26.7 | 76 |

| 2 1/2 x 2 | 73 | 60.3 | 89 |

| 2 1/2 x 1 1/2 | 73 | 48.3 | 89 |

| 2 1/2 x 1 1/4 | 73 | 42.2 | 89 |

| 2 1/2 x 1 | 73 | 33.4 | 89 |

| 3 x 2 1/2 | 88.9 | 73 | 89 |

| 3 x 2 | 88.9 | 60.3 | 89 |

| 3 x 1 1/2 | 88.9 | 48.3 | 89 |

| 3 x 1 1/4 | 88.9 | 42.2 | 89 |

| 3 1/2 x 3 | 101.6 | 88.9 | 102 |

| 3 1/2 x 21/2 | 101.6 | 73 | 102 |

| 3 1/2 x 2 | 101.6 | 60.3 | 102 |

| 3 1/2 x 1 1/2 | 101.6 | 48.3 | 102 |

| 3 1/2 x 1 1/4 | 101.6 | 42.2 | 102 |

| 4 x 3 1/2 | 114.3 | 101.6 | 102 |

| 4 x 3 | 114.3 | 88.9 | 102 |

| 4 x 2 1/2 | 114.3 | 73 | 102 |

| 4 x 2 | 114.3 | 60.3 | 102 |

| 4 x 1 1/2 | 114.3 | 48.3 | 102 |

| 5 x 4 | 141.3 | 114.3 | 127 |

| 5 x 3 1/2 | 141.3 | 101.6 | 127 |

| 5 x 3 | 141.3 | 88.9 | 127 |

| 5 x 2 1/2 | 141.3 | 73 | 127 |

| 5 x 2 | 141.3 | 60.3 | 127 |

| 6 x 5 | 168.3 | 141.3 | 140 |

| 6 x 4 | 168.3 | 114.3 | 140 |

| 6 x 3 1/2 | 168.3 | 101.6 | 140 |

| 6 x 3 | 168.3 | 88.9 | 140 |

| 6 x 2 1/2 | 168.3 | 73 | 140 |

| 8 x 6 | 219.1 | 168.3 | 152 |

| 8 x 5 | 219.1 | 141.3 | 152 |

| 8 x 4 | 219.1 | 114.3 | 152 |

| 8 x 3 1/2 | 219.1 | 101.6 | 152 |

| 10 x 8 | 273.1 | 219.1 | 178 |

| 10 x 6 | 273.1 | 168.1 | 178 |

| 10 x 5 | 273.1 | 141.3 | 178 |

| 10 x 4 | 273.1 | 114.3 | 178 |

| 12 x 10 | 323.9 | 273.1 | 203 |

| 12 x 8 | 323.9 | 219.1 | 203 |

| 12 x 6 | 323.9 | 168.3 | 203 |

| 12 x 5 | 323.9 | 141.3 | 203 |

| 14 x 12 | 355.6 | 323.9 | 330 |

| 14 x 10 | 355.6 | 273.1 | 330 |

| 14 x 8 | 355.6 | 219.1 | 330 |

| 14 x 6 | 355.6 | 168.3 | 330 |

| 16 x 14 | 406.4 | 355.6 | 356 |

| 16 x 12 | 406.4 | 323.9 | 356 |

| 16 x 10 | 406.4 | 273.1 | 356 |

| 16 x 8 | 406.4 | 219.1 | 356 |

| 16 x 6 | 406.4 | 168.3 | 356 |

| 18 x 16 | 457 | 406.4 | 381 |

| 18 x 14 | 457 | 355.6 | 381 |

| 18 x 12 | 457 | 323.9 | 381 |

| 18 x 10 | 457 | 273.1 | 381 |

| 18 x 8 | 457 | 219.1 | 381 |

| 20 x 18 | 508 | 457 | 508 |

| 20 x 16 | 508 | 406.4 | 508 |

| 20 x 14 | 508 | 355.6 | 508 |

| 20 x 12 | 508 | 323.9 | 508 |

| 20 x 10 | 508 | 273.1 | 508 |

| 20 x 8 | 508 | 219.1 | 508 |

| 22 x 20 | 559 | 508 | 508 |

| 22 x 18 | 559 | 457 | 508 |

| 22 x 16 | 559 | 406.4 | 508 |

| 22 x 14 | 559 | 355.6 | 508 |

| 22 x 12 | 559 | 323.9 | 508 |

| 24 x 10 | 559 | 273.1 | 508 |

| 24 x 22 | 610 | 559 | 508 |

| 24 x 20 | 610 | 508 | 508 |

| 24 x 18 | 610 | 457 | 508 |

| 24 x 16 | 610 | 406.4 | 508 |

| 24 x 14 | 610 | 355.6 | 508 |

| 24 x 12 | 610 | 323.9 | 508 |

| 24 x 10 | 610 | 273.1 | 508 |

| All Dimensions are in mm | |||

Features and Advantages

Corrosion Resistance: Stainless steel withstands chemical attack, oxidation, and rust, ensuring long-term durability.

Leak-Proof Joint: Butt-welded connections eliminate leakage risks, ensuring safe operations.

High-Temperature and Pressure Resistance: Suitable for demanding industrial applications.

Smooth Fluid Flow: The tapered design reduces turbulence and pressure drop.

Versatility: Available in various sizes, wall thicknesses, and stainless steel grades.

Low Maintenance: Resistant to wear, corrosion, and mechanical damage, reducing downtime.

Common Grades

SS 304 / 304L: Suitable for general applications, offering excellent corrosion resistance and weldability.

SS 316 / 316L: High resistance to chlorides and acids, ideal for marine and chemical applications.

SS 321 / 347: Stabilized grades for high-temperature applications, preventing carbide precipitation.

SS 904L: High-alloy stainless steel suitable for aggressive chemical environments.

Duplex & Super Duplex: High-strength stainless steels offering exceptional resistance to pitting and stress corrosion cracking.

Installation Considerations

Proper Welding: Butt welding requires skilled technicians to ensure a strong, leak-proof joint.

Alignment: Proper alignment is critical to prevent stress, turbulence, and uneven flow in pipelines.

Material Selection: Choose the stainless steel grade compatible with the fluid, pressure, and temperature conditions.

Inspection & Testing: Non-destructive testing (NDT) like radiography or ultrasonic testing ensures weld integrity.

Flow Direction: For eccentric reducers, align the flat side correctly to prevent air trapping or sediment accumulation.

Applications

1. Oil & Gas Industry

Used in upstream, midstream, and downstream pipelines.

Connects pipelines of varying diameters for crude oil, natural gas, and refined products.

Concentric reducers are ideal for vertical pipelines, while eccentric reducers prevent air accumulation in horizontal lines.

2. Chemical & Petrochemical Industry

Handles acids, alkalis, solvents, and other corrosive fluids.

Reducing tees and reducers ensure smooth flow in complex piping networks.

Eccentric reducers are preferred in pump suction lines to prevent cavitation and maintain process efficiency.

3. Power Generation

Used in high-pressure steam pipelines in thermal power plants.

Suitable for cooling water lines, condensate lines, and feedwater systems.

Ensures smooth transition in pipelines connecting different equipment sizes.

4. Food & Beverage Industry

Maintains hygiene and prevents contamination in fluid transport.

Stainless steel grades like 304L and 316L are preferred for sanitary applications.

Used in pipelines carrying milk, beverages, juices, and other fluids.

5. Pharmaceutical & Biotechnology

Ensures contamination-free fluid transfer.

Connects pipelines of different diameters for reactors, mixing tanks, and filtration systems.

Supports clean-in-place (CIP) operations due to corrosion resistance and smooth internal surfaces.

6. Water Treatment & Desalination Plants

Used in pipelines for potable water, wastewater, and brine transport.

Eccentric reducers prevent air accumulation, ensuring smooth flow in horizontal lines.

Suitable for aggressive chemical environments due to stainless steel’s resistance to corrosion.

7. Marine & Shipbuilding

Handles seawater, fuel lines, and cooling systems on ships and offshore platforms.

Provides durability and corrosion resistance in harsh marine environments.

8. Mining & Slurry Transport

Used in pipelines carrying abrasive slurries, chemicals, and high-pressure fluids.

Eccentric reducers prevent turbulence and wear caused by uneven flow.

Ensures reliable operation in extreme industrial conditions.

9. Construction & Infrastructure

Used in HVAC systems, fire-fighting pipelines, and high-rise building plumbing.

Connects pipelines of varying diameters with minimal pressure drop and enhanced durability.