Welded Steel Pipe

Welded Steel Pipe Manufacturer & Supplier

Welded steel pipes are one of the most widely used steel products in the global market due to their cost-effectiveness, consistent dimensions, and adaptability across industries. Unlike seamless pipes, which are formed from a solid billet, welded pipes are manufactured by rolling steel plates or coils into cylindrical shapes and welding the seams. This makes them an economical option for transporting fluids, gases, and solids, as well as for use in structural applications.

At Emirerri Steel, we specialize in supplying high-quality welded steel pipes that meet international standards, ensuring reliability, durability, and precision. With a broad product portfolio including ERW, LSAW, SSAW, and HFIW pipes, we cater to industries such as oil & gas, construction, petrochemicals, water treatment, and power generation.

What is a Welded Steel Pipe?

A welded steel pipe is produced by bending steel plates or coils into a cylindrical form and welding the seam using different techniques. The weld can be longitudinal (straight seam) or spiral (helical seam), depending on the production method.

Key characteristics of welded pipes include:

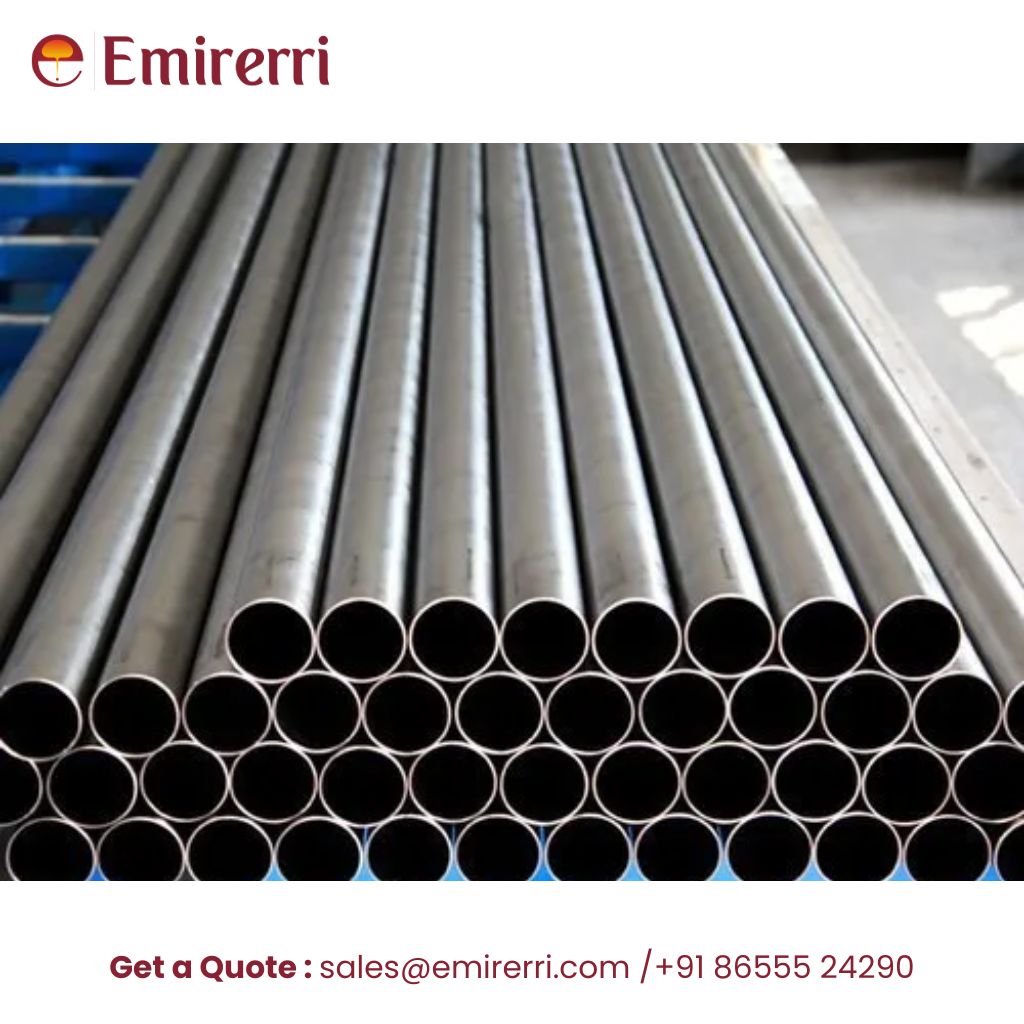

High dimensional accuracy

Smooth surface finish

Cost-effectiveness compared to seamless pipes

Availability in larger diameters and long lengths

Suitability for low to medium pressure applications

Manufacturing Process of Welded Steel Pipe

The production process of welded steel pipe varies depending on the method but generally includes:

Raw Material Selection

High-quality steel plates or coils are chosen based on the desired grade and specification.

Forming

The plate or strip is rolled into a cylindrical shape either by longitudinal bending or spiral rolling.

Welding

The edges are welded together using techniques such as Electric Resistance Welding (ERW), Submerged Arc Welding (SAW), or High-Frequency Induction Welding (HFIW).

Heat Treatment

Pipes may undergo post-weld heat treatment to relieve stress and enhance mechanical properties.

Sizing & Shaping

Pipes are passed through sizing mills to achieve precise dimensions and roundness.

Inspection & Testing

Pipes are subjected to hydrostatic testing, ultrasonic testing, and visual inspection to ensure compliance with ASTM, API, EN, and ISO standards.

Types of Welded Steel Pipes

Welded pipes come in different types based on manufacturing technology and application:

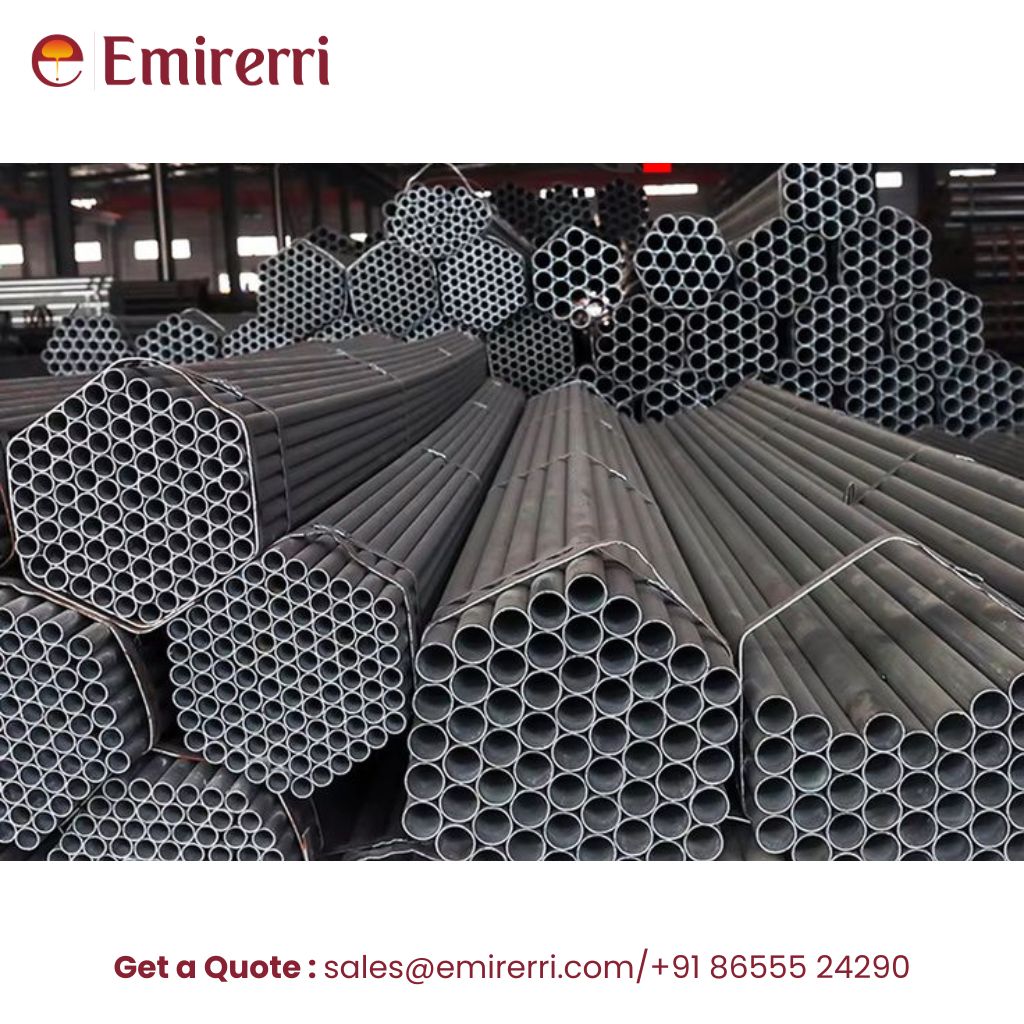

ERW (Electric Resistance Welded) Pipe

Produced by cold-forming steel coils and welding the seam using electrical resistance. Commonly used for water pipelines, scaffolding, and low-pressure applications.

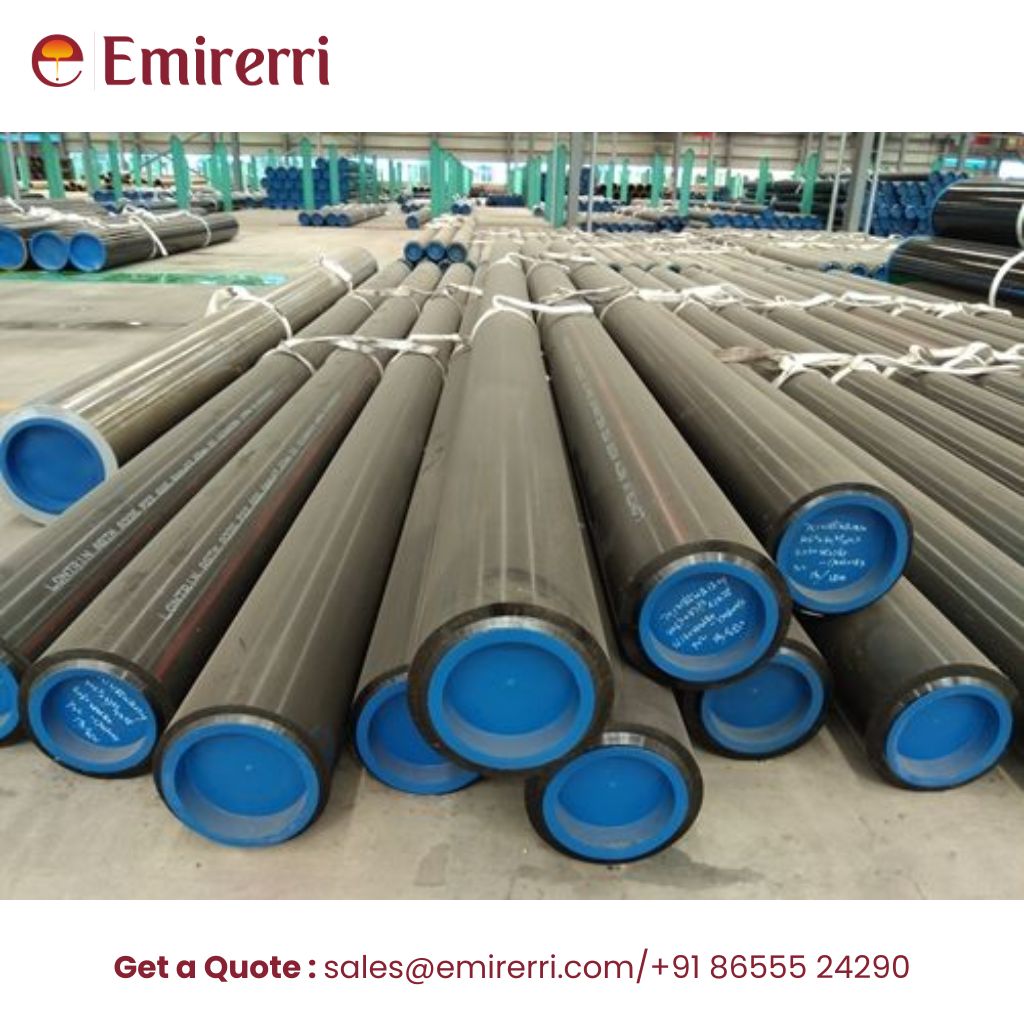

LSAW (Longitudinal Submerged Arc Welded) Pipe

Manufactured by bending plates and welding longitudinal seams. Suitable for high-pressure and long-distance oil & gas pipelines.

SSAW (Spiral Submerged Arc Welded) Pipe

Made by spiral rolling steel plates and welding helically. Ideal for large-diameter pipelines in water, oil, and gas transmission.

HFIW (High-Frequency Induction Welded) Pipe

Welded using high-frequency induction for strong seam bonding. Widely used in structural applications and fluid transportation.

Advantages of Welded Steel Pipe

Welded pipes are chosen for numerous applications due to their distinct advantages:

Cost-Effective Solution – Less expensive compared to seamless pipes, making them economical for large projects.

Availability in Large Sizes – Can be manufactured in large diameters, making them suitable for infrastructure projects.

High Dimensional Accuracy – Consistent wall thickness and surface finish due to controlled manufacturing.

Versatility – Can be used in water supply, oil & gas, structural supports, and mechanical applications.

Customization – Easy to produce with different coatings, thicknesses, and lengths according to project needs.

Applications of Welded Steel Pipe

Welded steel pipes play a critical role across multiple sectors:

Oil & Gas Industry

Used in long-distance transportation pipelines for crude oil, natural gas, and petroleum products.

Construction & Infrastructure

Applied in structural frameworks, bridges, piling, and scaffolding.

Water Supply & Sewage Systems

Ideal for transporting potable water, wastewater, and industrial fluids.

Power Generation & Energy

Used in boilers, heat exchangers, and high-temperature equipment.

Mechanical & Automotive

Employed in exhaust systems, chassis, and machinery parts.

Agriculture & Irrigation

Used in irrigation pipelines, drainage systems, and agricultural machinery.

Carbon Steel Pipes & Tubes

ASTM A106 / SA106

ASTM A53 / SA53

ASTM A179 / SA179

ASTM A192 / SA192

ASTM A210 / SA210

ASTM A333 / SA333

ASTM A500

ASTM A513

ASTM A519

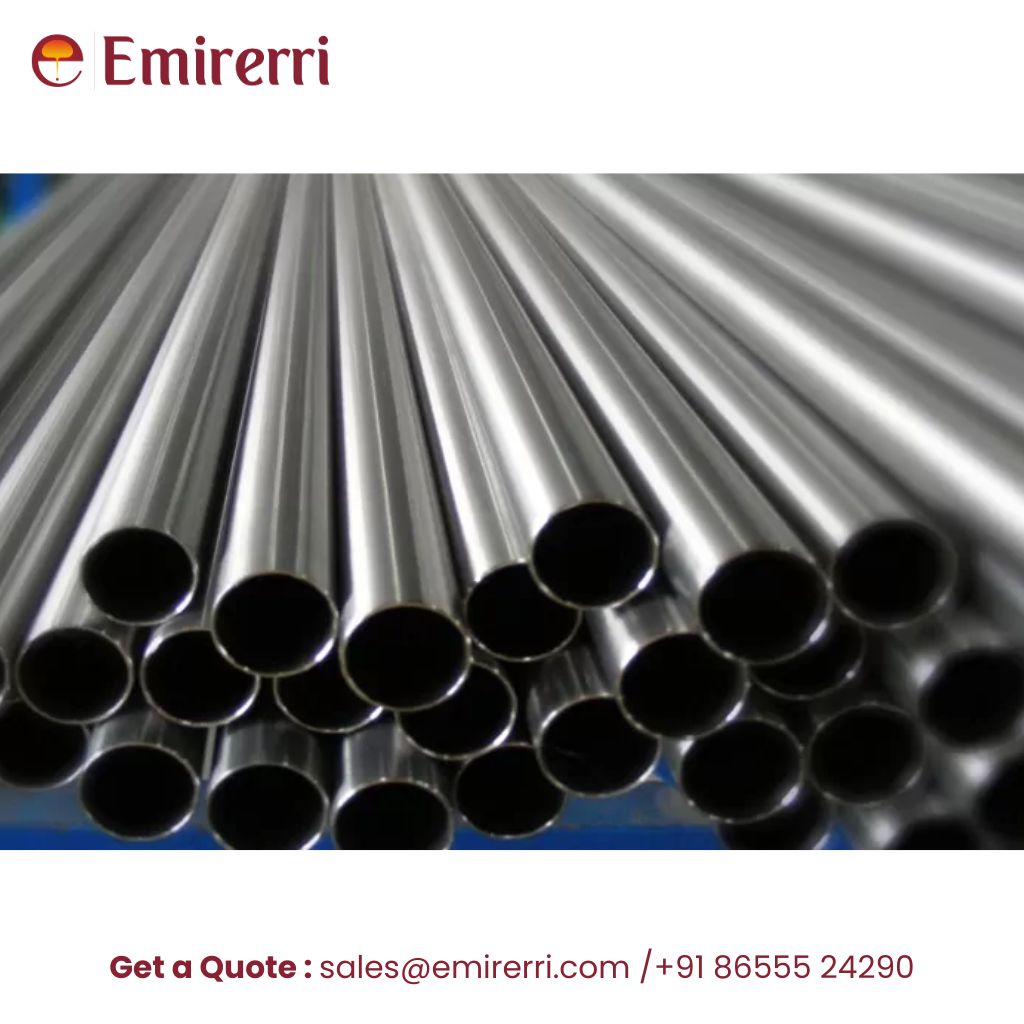

Stainless Steel Pipes & Tubes

ASTM A213 / ASME SA213

ASTM A269 / ASME SA269

ASTM A312 / ASME SA312

ASTM A249 / ASME SA249

ASTM A554 / ASME SA554

Duplex & Super Duplex Steel

ASTM A789

ASTM A790

Alloy Steel Pipes & Tubes

ASTM A213 / ASME SA213

ASTM A335 / ASME SA335

ASTM A209 / ASME SA209

ASTM A369 / ASME SA369

Nickel Alloy Pipes & Tubes

ASTM B161

ASTM B163

ASTM B165

ASTM B725

ASTM B167

ASTM B423

ASTM B622

ASTM B626

Titanium Pipes & Tubes

ASTM B338

ASTM B861

Copper Alloy Tubes

ASTM B88

ASTM B111

ASTM B466

Why Choose Emirerri Steel for Welded Steel Pipes?

Diverse Range – ERW, LSAW, SSAW, and HFIW pipes available in multiple grades.

Quality Assurance – Strict adherence to ASTM, API, EN, and ISO standards.

Global Reach – Trusted supplier to industries worldwide.

Customization – Pipes tailored in length, coating, and finishing as per customer requirements.

Competitive Pricing – High-quality products at cost-effective prices.

On-Time Delivery – Robust supply chain and large inventory for fast delivery.