ASTM A105

ASTM A105 Carbon Steel Pipe Fittings

ASTM A105 Carbon Steel Pipe Fittings are a type of forged carbon steel fitting known for their durability and high strength. These fittings are typically used in pressure systems, pipelines, and high-temperature environments, making them ideal for industries like oil and gas, petrochemicals, and power generation.

Key Features:

- Material: Made from ASTM A105 forged carbon steel, which provides excellent durability and toughness, making them suitable for various high-pressure applications.

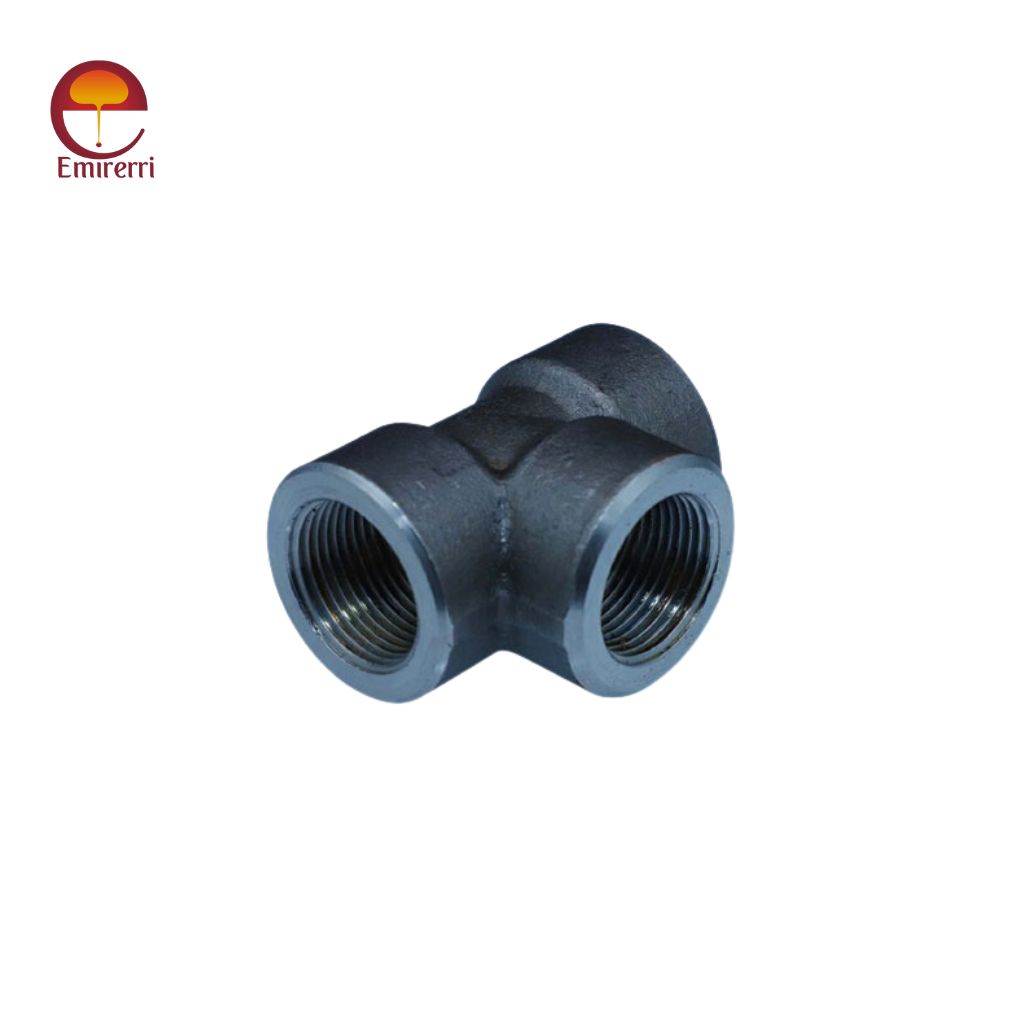

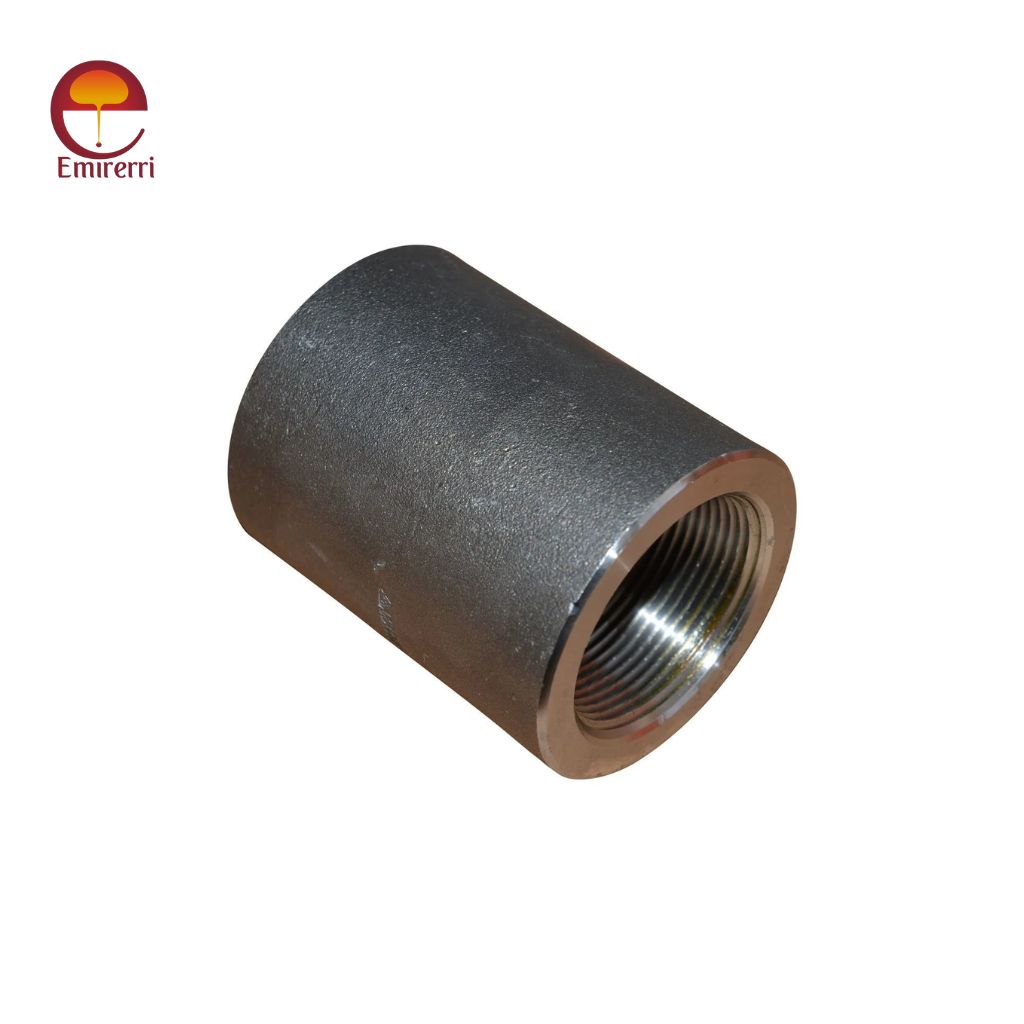

- Types: Available in a range of shapes and styles, including elbows, tees, couplings, unions, caps, and reducers to accommodate different pipeline configurations.

- Pressure Rating: These fittings are often rated for higher pressures, suitable for ANSI standards, such as Class 150, Class 300, and Class 600.

- Temperature Tolerance: ASTM A105 fittings perform well in high-temperature environments, maintaining integrity even in challenging conditions.

Types of Carbon Steel Forged Fittings

Carbon Steel Socket Weld Fittings

Threaded (Screwed) Fittings:

Special / Custom Forged Fittings

Boss

Swage Nipple

Reducing Insert

Adapter

Street Elbow

Class Ratings

Class 2000

Class 3000

Class 6000

Class 9000

Connection Types

Socket Weld (SW) – For permanent welded joints

Threaded (NPT / BSP) – For detachable connections

Applications

Oil & Gas Transmission Pipelines

Petrochemical and Refinery Plants

Power Generation & Thermal Plants

Shipbuilding and Marine Systems

Industrial Process Piping

Water Treatment and Utility Lines

Standards & Grades

Manufacturing Standards:

ASTM A105 / ASME SA105 – Carbon Steel Forgings for Piping Applications

ASTM A350 LF2 / LF3 – Low-Temperature Carbon Steel Forgings

ASTM A694 (F42–F70) – High-Strength Carbon Steel Forgings for Pipeline Applications

ASME B16.11 – Forged Fittings, Socket-Welding, and Threaded

MSS-SP-79 / MSS-SP-83 / MSS-SP-95 – Forged Steel Fitting Specifications

Available Grades:

| Grade | Description |

|---|---|

| ASTM A105 | Standard grade for forged carbon steel fittings used in ambient- and high-temperature service. |

| ASTM A350 LF2 | Low-temperature carbon steel with excellent notch toughness. |

| ASTM A694 F42 – F70 | High-strength carbon steel used for oil & gas pipeline systems and high-pressure service. |

ASTM A105 Material Equivalent

| Standard | Country | Grade |

|---|---|---|

| ASTM A105 | USA | A105 |

| EN 10222-2 | Europe | P245GH / P280GH |

| DIN 17243 | Germany | C22.8 |

| JIS G4051 / JIS G3101 | Japan | S25C / SS400 |

| IS 1875 | India | C22 |

| GOST 1050 | Russia | 20 / 25 |

A105 Mechanical Properties

| Element | Composition (Weight %) |

|---|---|

| Carbon (C) | 0.35 max |

| Manganese (Mn) | 0.60 – 1.05 |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.05 max |

| Silicon (Si) | 0.10 – 0.35 |

| Copper (Cu) | 0.40 max |

| Nickel (Ni) | 0.30 max |

| Chromium (Cr) | 0.30 max |

| Molybdenum (Mo) | 0.12 max |

| Vanadium (V) | 0.10 max |

A105 Physical Properties

| Property | Value |

|---|---|

| Density | 7.85 g/cm³ (7850 kg/m³) |

| Melting Point | 2,600°F (1,426°C) |

| Thermal Conductivity | 26.2 W/m·K (at 100°C) |

| Specific Heat | 0.48 J/g·K (at 25°C) |

| Electrical Resistivity | 0.00049 ohm·cm |

| Coefficient of Thermal Expansion | 11.7 µm/m·°C (at 20°C to 100°C) |

Compliance and Testing

Compliance and testing for ASTM A105 carbon steel involve a set of quality control processes to ensure the material meets safety, durability, and reliability standards for use in pressure systems and piping applications.

Chemical Composition Testing

- Conducted to confirm that the chemical elements in the steel meet ASTM A105 standards.

- Methods: Typically performed using spectrometry or other chemical analysis methods.

- Elements Tested: Carbon, manganese, phosphorus, sulfur, silicon, and optional elements like copper, nickel, chromium, molybdenum, and vanadium.

Mechanical Properties Testing

- Tensile Testing: Determines the material’s tensile strength, yield strength, and elongation percentage. ASTM A105 requires:

- Minimum tensile strength of 485 MPa.

- Minimum yield strength of 250 MPa.

- Hardness Testing: Verifies that hardness does not exceed 187 HBW (Brinell Hardness).

- Impact Testing: Required when the material is used in low-temperature applications or for sizes with higher wall thicknesses. Charpy V-notch test is commonly performed.

Heat Treatment

- While normalizing is optional, it is recommended for applications requiring enhanced mechanical properties.

- After heat treatment, materials are tested to confirm adherence to the specified mechanical properties.

Non-Destructive Examination (NDE)

- This is optional based on project specifications but may include methods such as:

- Ultrasonic Testing (UT): Checks for internal discontinuities or flaws.

- Magnetic Particle Testing (MT): Used for detecting surface and near-surface defects.

- Liquid Penetrant Testing (PT): Suitable for finding surface-breaking defects.

- Typically done when specific projects demand enhanced safety and reliability.

Hydrostatic Testing

Flanges and fittings made of ASTM A105 do not require hydrostatic testing under the ASTM standard, as they are designed to withstand system pressures. However, they may be pressure tested as part of system installation.

Partner with Emirerri Steel — Where Quality Meets Reliability.

Get in Touch Today for a Custom Quote!