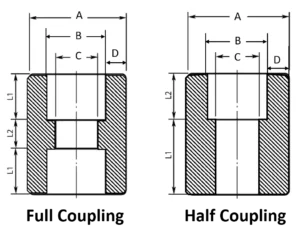

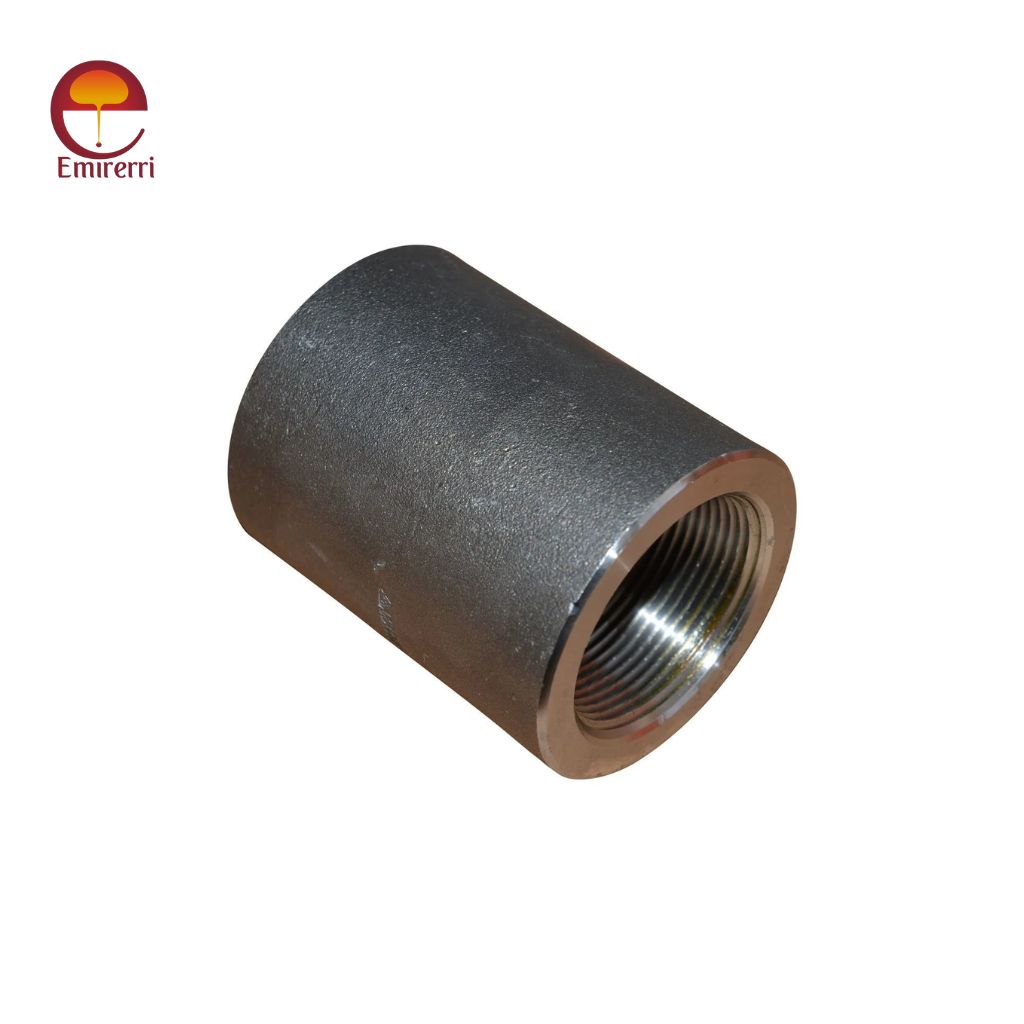

ASTM A105 Coupling (Half & Full)

ASTM A105 Coupling is a premium forged carbon steel fitting designed to connect two pipes or tubes of the same size, ensuring a secure and leak-proof joint. Manufactured to meet the rigorous ASTM A105 standard, these couplings offer excellent strength and durability in a wide range of applications, from oil and gas to chemical industries.

Key Features

- Material: Constructed from high-quality carbon steel, in compliance with ASTM A105 standards, providing superior strength and corrosion resistance.

- Design: Available in standard, reducing, and threaded configurations for versatility in various piping applications.

- End Types: Can be supplied with threaded (NPT), socket weld, or butt weld ends to suit different installation needs.

- Pressure Ratings: Suitable for high-pressure systems, with various pressure classes available.

Specifications

- Standards: Meets ASTM A105 and ASME B16.9/B16.11 standards for quality and performance.

- Sizes: Available from ½” to 48″ NPS in various configurations.

- Dimensions: Tailored for a precise fit in standard and custom configurations.

- Surface Finish: Offered in black, galvanized, or custom coating options for different environments.

ASTM A105 Socket Weld Coupling Dimensions

| NOMINAL PIPE SIZE | OUTER DIAMETER | SOCKET BORE DIAMETER | BORE DIAMETER OF FITTINGS | BORE DIAMETER OF FITTINGS | BORE DIAMETER OF FITTINGS | WALL THICKNESS # 3000 |

WALL THICKNESS # 3000 |

WALL THICKNESS # 6000 |

WALL THICKNESS # 6000 |

WALL THICKNESS # 9000 |

WALL THICKNESS # 9000 |

FULL COUPLING | FULL COUPLING | HALF COUPLING | HALF COUPLING |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch. | A | B | C – 3000 | C – 6000 | C – 9000 | D | D | D | D | D | D | L1 | L2 | L1 | L2 |

| Maximum Minimum |

Maximum Minimum |

Maximum Minimum |

Maximum Minimum |

Average | Minimum | Average | Minimum | Average | Minimum | ||||||

| 1/8 | B+D | 11.2 10.8 |

7.6 6.1 |

4.8 3.2 |

3.18 | 3.18 | 3.96 | 3.43 | 9.5 | 6.5 | 9.5 | 16.0 | |||

| 1/4 | B+D | 14.6 14.2 |

10.0 8.5 |

7.1 5.6 |

3.78 | 3.30 | 4.6 | 4.01 | 9.5 | 6.5 | 9.5 | 16.0 | |||

| 3/8 | B+D | 18.0 17.6 |

13.3 11.8 |

9.9 8.4 |

4.01 | 3.50 | 5.03 | 4.37 | 9.5 | 6.5 | 9.5 | 17.5 | |||

| 1/2 | B+D | 22.2 21.8 |

16.6 15.0 |

12.5 11.0 |

7.2 5.6 |

4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 9.5 | 9.5 | 9.5 | 22.5 |

| 3/4 | B+D | 27.6 27.2 |

21.7 20.2 |

16.3 14.8 |

11.8 10.3 |

4.90 | 4.27 | 6.96 | 6.04 | 9.78 | 8.56 | 12.5 | 9.5 | 12.5 | 24.0 |

| 1 | B+D | 34.3 33.9 |

27.4 25.9 |

21.5 19.9 |

16.0 14.4 |

5.69 | 4.98 | 7.92 | 6.93 | 11.38 | 9.96 | 12.5 | 12.5 | 12.5 | 28.5 |

| 1 1/4 | B+D | 43.1 42.7 |

35.8 34.3 |

30.2 28.7 |

23.5 22.0 |

6.07 | 5.28 | 7.92 | 6.93 | 12.14 | 10.62 | 12.5 | 12.5 | 12.5 | 30.0 |

| 1 1/2 | B+D | 49.2 48.8 |

41.6 40.1 |

34.7 33.2 |

28.7 27.2 |

6.35 | 5.54 | 8.92 | 7.8 | 12.7 | 11.12 | 12.5 | 12.5 | 12.5 | 32.0 |

| 2 | B+D | 61.7 61.2 |

53.3 51.7 |

43.6 42.1 |

38.9 37.4 |

6.93 | 6.04 | 10.92 | 9.5 | 13.84 | 12.12 | 16.0 | 19.0 | 16.0 | 41.0 |

| 2 1/2 | B+D | 74.4 73.9 |

64.2 61.2 |

8.76 | 7.67 | 16.0 | 19.0 | 16.0 | 43.0 | ||||||

| 3 | B+D | 90.3 89.8 |

79.4 76.4 |

9.52 | 8.30 | 16.0 | 19.0 | 16.0 | 44.5 | ||||||

| 4 | B+D | 103.8 100.7 |

103.8 100.7 |

10.69 | 9.35 | 16.0 | 19.0 | 16.0 | 48.0 | ||||||

| All Dimensions are in mm | |||||||||||||||

ASTM A105 Tolerance

| NOMINAL PIPE SIZE | ALL FITTINGS | ALL FITTINGS | ALL FITTINGS | ELBOWS AND TEES | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | 180 DEG RETURN BENDS | REDUCERS | CAPS |

| NPS | O.D. at Bevel (1), (2) | I.D. at End | Wall Thickness (3) | Centre-to-End Dimension A,B,C,M | Centre-to-Centre O | Back-to-Face K | Alignment of Ends U | Overall Length H | Overall Length E |

| (1), (3), (4) | |||||||||

| ½ to 2½ | 0.06 | 0.03 | Not less than 87.5% of nominal thickness | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| -0.03 | |||||||||

| 3 to 3 ½ | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 4 | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 5 to 8 | 0.09 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 | |

| -0.06 | |||||||||

| 10 to 18 | 0.16 | 0.12 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| -0.12 | |||||||||

| 20 to 24 | 0.25 | 0.19 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| -0.19 | |||||||||

| 26 to 30 | 0.25 | 0.19 | 0.12 | … | … | … | 0.19 | 0.38 | |

| -0.19 | |||||||||

| 32 to 48 | 0.25 | 0.19 | 0.19 | … | … | … | 0.19 | 0.38 | |

| -0.19 |

Benefits

- Robust mechanical properties and corrosion resistance.

- Leak-proof and durable connections for long-term performance.

- High-quality construction for use in demanding high-pressure and high-temperature systems.

Applications

- Oil & Gas: Ideal for pipeline connections in the oil and gas sector.

- Petrochemical: Commonly used in refining and chemical plant systems.

- Power Generation: Essential in steam and water piping for power plants.

- General Industry: Used in various industrial applications for fluid and gas transportation.

Reviews

There are no reviews yet.