Seamless Steel Pipe

Seamless Steel Pipe Manufacturer & Supplier

Seamless steel pipes are among the most reliable and widely used products in the steel industry, known for their exceptional strength, durability, and ability to withstand extreme pressure. Unlike welded pipes, seamless pipes are manufactured without any joints or seams, giving them superior mechanical properties and ensuring leak-proof performance. Their versatility makes them indispensable across various industries, including oil & gas, power generation, petrochemicals, construction, automotive, shipbuilding, and heavy engineering.

At Emirerri Steel, we specialize in the supply and export of high-quality seamless steel pipes that meet international standards and deliver unmatched performance. With years of expertise, we ensure precision manufacturing, strict quality checks, and timely delivery to cater to global markets.

What is a Seamless Steel Pipe?

A seamless steel pipe is a hollow cylindrical product made from solid steel billets through extrusion, piercing, or rotary rolling processes. Unlike welded pipes, which are made by rolling a plate and welding the seam, seamless pipes have no weak points, making them stronger and more reliable for critical applications.

Key characteristics of seamless pipes include:

High strength-to-weight ratio

Excellent corrosion and heat resistance

Uniform structure without weld defects

High-pressure and high-temperature sustainability

Manufacturing Process of Seamless Steel Pipe

The production of seamless steel pipe involves multiple stages to ensure accuracy and performance. The most common methods include:

Billet Preparation

High-quality steel billets are heated to an optimum temperature to make them malleable.

Piercing Process

The billet is pierced using a mandrel or rotary piercer to create a hollow tube.

Rolling & Elongation

The pierced billet is rolled and elongated to achieve the desired diameter and wall thickness.

Sizing & Finishing

Pipes are passed through sizing mills for dimensional accuracy. Heat treatment and finishing processes improve toughness and surface quality.

Testing & Inspection

Non-destructive tests, hydrostatic tests, and visual inspections ensure pipes meet international standards like ASTM, ASME, API, EN, DIN, and JIS.

Advantages of Seamless Steel Pipe

Seamless pipes are preferred over welded alternatives due to several distinct advantages:

Superior Strength & Reliability – With no weld seam, these pipes eliminate weak points, making them ideal for high-pressure environments.

Uniformity in Structure – The homogeneous composition ensures consistent mechanical properties throughout the pipe length.

Corrosion & Heat Resistance – Ideal for handling corrosive fluids and high-temperature applications.

Leak-Proof & Safe – Seamless construction ensures leak-free operation in oil, gas, and chemical transport.

Longer Service Life – Enhanced durability reduces maintenance costs and increases operational efficiency.

Applications of Seamless Steel Pipe

Seamless steel pipes are highly versatile and serve a wide range of industries, including:

Oil & Gas Industry

Used for drilling, pipeline transport, casing, and tubing in upstream, midstream, and downstream operations.

Power Plants

Essential in boilers, superheaters, and heat exchangers where high pressure and temperature resistance are critical.

Petrochemical Industry

Suitable for transporting chemicals, refining processes, and building process equipment.

Construction & Infrastructure

Used in structural frameworks, piling, and civil engineering projects for their strength and durability.

Automobile & Mechanical Engineering

Applied in axles, bearings, cylinder parts, and precision machinery components.

Shipbuilding & Marine Industry

Resistant to seawater corrosion and high-pressure systems in ship structures and offshore platforms.

Types of Seamless Steel Pipes

Seamless pipes come in different types depending on material and application:

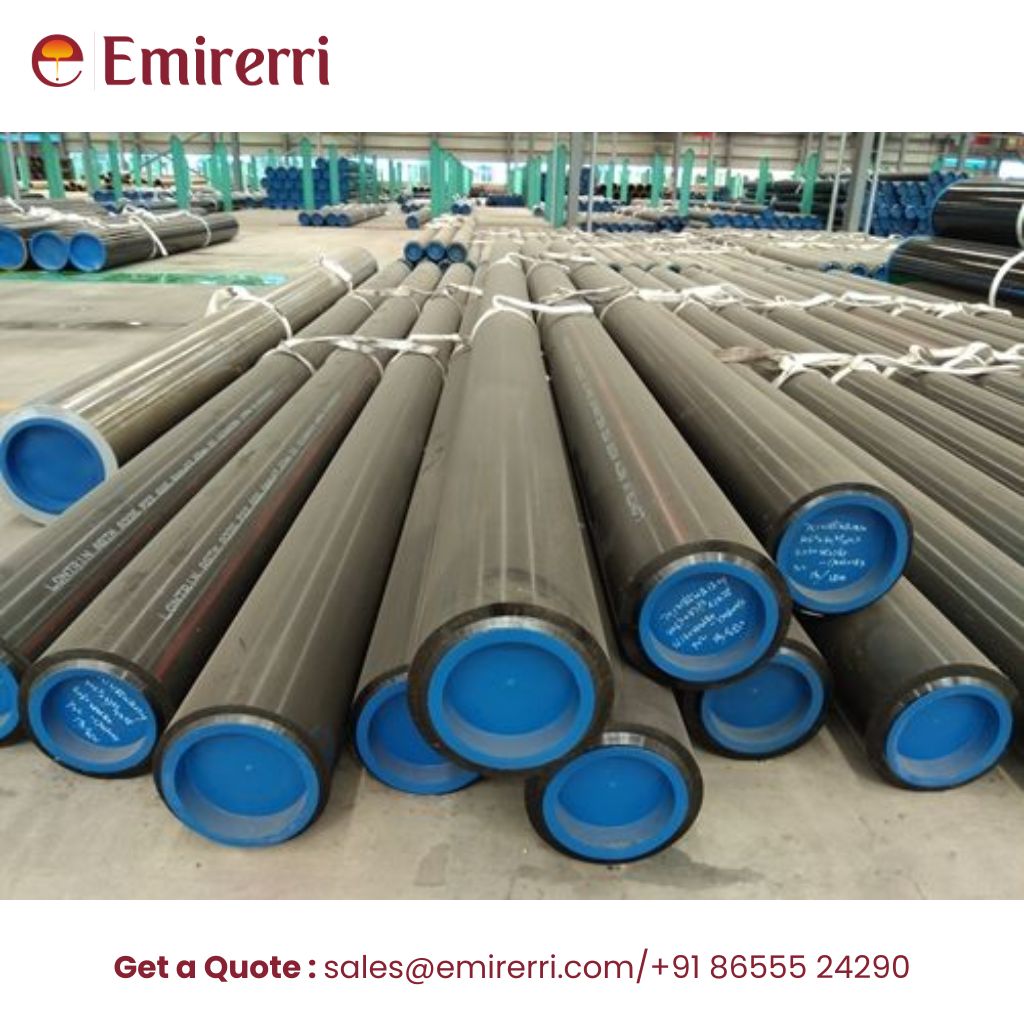

Carbon Steel Seamless Pipe

High strength and toughness; commonly used in oil & gas, mechanical engineering, and structural applications.

Alloy Steel Seamless Pipe

Enhanced with alloying elements for better hardness, wear resistance, and heat resistance.

Stainless Steel Seamless Pipe

Excellent corrosion resistance; ideal for chemical, pharmaceutical, and food industries.

Nickel Alloy Seamless Pipe

Superior resistance to high-temperature oxidation and corrosive chemicals; used in specialized industries.

Duplex & Super Duplex Seamless Pipe

Combines high strength with excellent corrosion resistance, especially for marine and offshore projects.

Standards & Specifications

Carbon Steel Seamless Tubing – Grades by Standard

ASTM / ASME

ASTM A106 / SA106 → Grades A, B, C

ASTM A53 / SA53 → Grades A, B

ASTM A179 / SA179 → Low-Carbon Steel (single grade, no subdivisions)

ASTM A192 / SA192 → High-Pressure Carbon Steel (single grade)

ASTM A210 / SA210 → Grades A-1, C

ASTM A333 / SA333 → Grades 1, 3, 4, 6, 7, 8, 9, 10, 11 (low-temperature service)

ASTM A500 → Grades A, B, C, D (structural tubing)

ASTM A513 → Various grades depending on type (e.g., 1010, 1020, 1026)

ASTM A519 → Grades like 1010, 1020, 1026, 4130, 4140

API (Oil & Gas)

API 5L → Grades A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80

API 5CT → Grades H40, J55, K55, N80, L80, C90, T95, P110, Q125

EN / DIN

EN 10216-1 → Grades P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2

EN 10216-2 → Grades P235GH, P265GH, 16Mo3, 13CrMo4-5, 10CrMo9-10

DIN 1629 → Grades St 37.0, St 44.0, St 52.0

DIN 17175 → Grades St35.8, St45.8, 15Mo3, 13CrMo44

BS (British Standards)

BS 3059 Part 1 → Grades 320, 360

BS 3059 Part 2 → Grades 243, 360, 440

BS 3602 → Grades like 360, 410 (for pressure purposes)

JIS (Japanese Standards)

JIS G3454 → Grades STPG 370, STPG 410

JIS G3455 → Grades STS 370, STS 410

JIS G3456 → Grades STPT 370, STPT 410, STPT 480

Stainless Steel Seamless Tubing Standards & Grades

ASTM / ASME (American Standards)

ASTM A213 / ASME SA213 → Seamless Austenitic & Ferritic Stainless Steel Tubes for Boilers, Superheaters & Heat Exchangers

Grades: TP304, TP304H, TP304L, TP316, TP316H, TP316L, TP317, TP321, TP321H, TP347, TP347H, TP310S, TP904L

ASTM A269 / ASME SA269 → Seamless & Welded Austenitic Stainless Steel Tubes for General Service

Grades: TP304, TP304L, TP316, TP316L, TP321, TP347

ASTM A312 / ASME SA312 → Seamless Austenitic Stainless Steel Pipes (often used for larger-diameter tubing as well)

Grades: TP304, TP304L, TP316, TP316L, TP321, TP347, TP310S, TP904L, Duplex Grades

ASTM A249 / ASME SA249 → Welded Austenitic Stainless Steel Tubes (but also often referenced alongside seamless for interchange)

ASTM A269 / A213 → Cold-Drawn Seamless Tubes for High Precision Applications

EN / DIN (European Standards)

EN 10216-5 → Seamless Stainless Steel Tubes for Pressure Purposes

Grades: 1.4301 (304), 1.4306 (304L), 1.4541 (321), 1.4401 (316), 1.4404 (316L), 1.4571 (316Ti), 1.4438 (317L), 1.4539 (904L)

DIN 17456 / 17458 → Seamless Austenitic Stainless Steel Tubes for General & Pressure Service

Grades: X5CrNi18-10 (304), X2CrNi19-11 (304L), X5CrNiMo17-12-2 (316), X2CrNiMo17-12-2 (316L), X6CrNiTi18-10 (321), X6CrNiNb18-10 (347)

BS (British Standards)

BS EN 10216-5 (aligned with EN) – Seamless Stainless Steel Tubes for Pressure

BS 3605 → Austenitic Stainless Steel Pipes & Tubes for Pressure & General Purposes

Grades: 304, 304L, 316, 316L, 321, 347

JIS (Japanese Standards)

JIS G3459 → Stainless Steel Pipes for General Service

Grades: SUS304, SUS304L, SUS316, SUS316L, SUS321, SUS347

JIS G3463 → Stainless Steel Boiler & Heat Exchanger Tubes

Grades: SUS304, SUS304L, SUS316, SUS316L, SUS321, SUS347, SUS310S

Special Grades (High Performance)

Duplex & Super Duplex Stainless Steel → UNS S31803 (2205), S32205, S32750, S32760

Nickel Alloys / Special Grades (sometimes classified alongside stainless seamless tubing) → Alloy 20, 904L, Hastelloy grades

Alloy Steel Seamless Tubing – Standards & Grades

ASTM / ASME (American Standards)

ASTM A213 / ASME SA213 – Seamless Ferritic & Austenitic Alloy Steel Tubes for Boilers, Superheaters, and Heat Exchangers

Grades: T2, T5, T9, T11, T12, T22, T23, T24, T91, T92, T122, T911

ASTM A335 / ASME SA335 – Seamless Ferritic Alloy Steel Pipes (often supplied as tubing for high-temperature service)

Grades: P1, P2, P5, P9, P11, P12, P22, P23, P24, P91, P92, P122, P911

ASTM A209 / ASME SA209 – Seamless Carbon-Molybdenum Alloy Steel Boiler & Superheater Tubes

Grades: T1, T1a, T1b

ASTM A369 / ASME SA369 – Seamless Ferritic Alloy Steel Pipe for High-Temperature Service

Grades: FW, FP1, FP2, FP5, FP9, FP11, FP12, FP22, FP91

EN / DIN (European Standards)

EN 10216-2 – Seamless Tubes for Pressure Purposes, Non-Alloy & Alloy Steels with Specified Elevated Temperature Properties

Grades: 10CrMo9-10, 13CrMo4-5, 14MoV6-3, X11CrMo5, X10CrMoVNb9-1 (P91), X10CrWMoVNb9-2 (P92)

DIN 17175 – Seamless Tubes of Heat-Resistant Steels

Grades: 15Mo3, 13CrMo44, 10CrMo910, X20CrMoV121

BS (British Standards)

BS 3059 Part 2 – Alloy Steel Tubes for Boiler & Heat Exchanger Service

Grades: 360, 440 (with alloying elements)

BS 3604 – Alloy Steel Seamless Tubes for Pressure Purposes

Grades: Equivalent to ASTM P & T series

JIS (Japanese Standards)

JIS G3462 – Alloy Steel Tubes for Boiler and Heat Exchanger Service

Grades: STBA 12, STBA 20, STBA 22, STBA 23, STBA 24, STBA 25

JIS G3458 – Alloy Steel Pipes for High-Temperature Service

Grades: STS 370, STS 410, STS 480, STS 530 (with Cr-Mo alloy content)

Carbon Steel Pipes & Tubes

ASTM A106 / SA106

ASTM A53 / SA53

ASTM A179 / SA179

ASTM A192 / SA192

ASTM A210 / SA210

ASTM A333 / SA333

ASTM A500

ASTM A513

ASTM A519

Stainless Steel Pipes & Tubes

ASTM A213 / ASME SA213

ASTM A269 / ASME SA269

ASTM A312 / ASME SA312

ASTM A249 / ASME SA249

ASTM A554 / ASME SA554

Duplex & Super Duplex Steel

ASTM A789

ASTM A790

Alloy Steel Pipes & Tubes

ASTM A213 / ASME SA213

ASTM A335 / ASME SA335

ASTM A209 / ASME SA209

ASTM A369 / ASME SA369

Nickel Alloy Pipes & Tubes

ASTM B161

ASTM B163

ASTM B165

ASTM B725

ASTM B167

ASTM B423

ASTM B622

ASTM B626

Titanium Pipes & Tubes

ASTM B338

ASTM B861

Copper Alloy Tubes

ASTM B88

ASTM B111

ASTM B466

Why Choose Emirerri Steel for Seamless Steel Pipes?

Extensive Product Range – Carbon, alloy, stainless, and specialty seamless pipes in multiple grades.

Global Standards Compliance – All products conform to ASTM, ASME, API, EN, and other international norms.

Stringent Quality Control – Each pipe undergoes chemical analysis, mechanical testing, and non-destructive examinations.

Customization Options – Pipes available in various diameters, thicknesses, lengths, and coatings to meet project-specific needs.

Timely Delivery – Efficient supply chain and large stock ensure on-time delivery across the globe.

Global Clientele – Trusted by industries in oil & gas, energy, marine, and construction worldwide.