Stainless Steel Flange

Stainless Steel Flange

Manufacturer, Supplier & Exporter

Emirerri Steel is a trusted manufacturer, supplier, and exporter of Stainless Steel Flanges that meet international standards such as ASME, ANSI, DIN, EN, and BS. Our precision-engineered flanges ensure superior performance, durability, and leak-proof connections across diverse piping systems and industries including petrochemical, oil & gas, shipbuilding, water treatment, and power generation.

We offer stainless steel flanges in a wide range of types, materials, pressure ratings, and sizes, suitable for both standard and customized applications.

Types of Stainless Steel Flanges

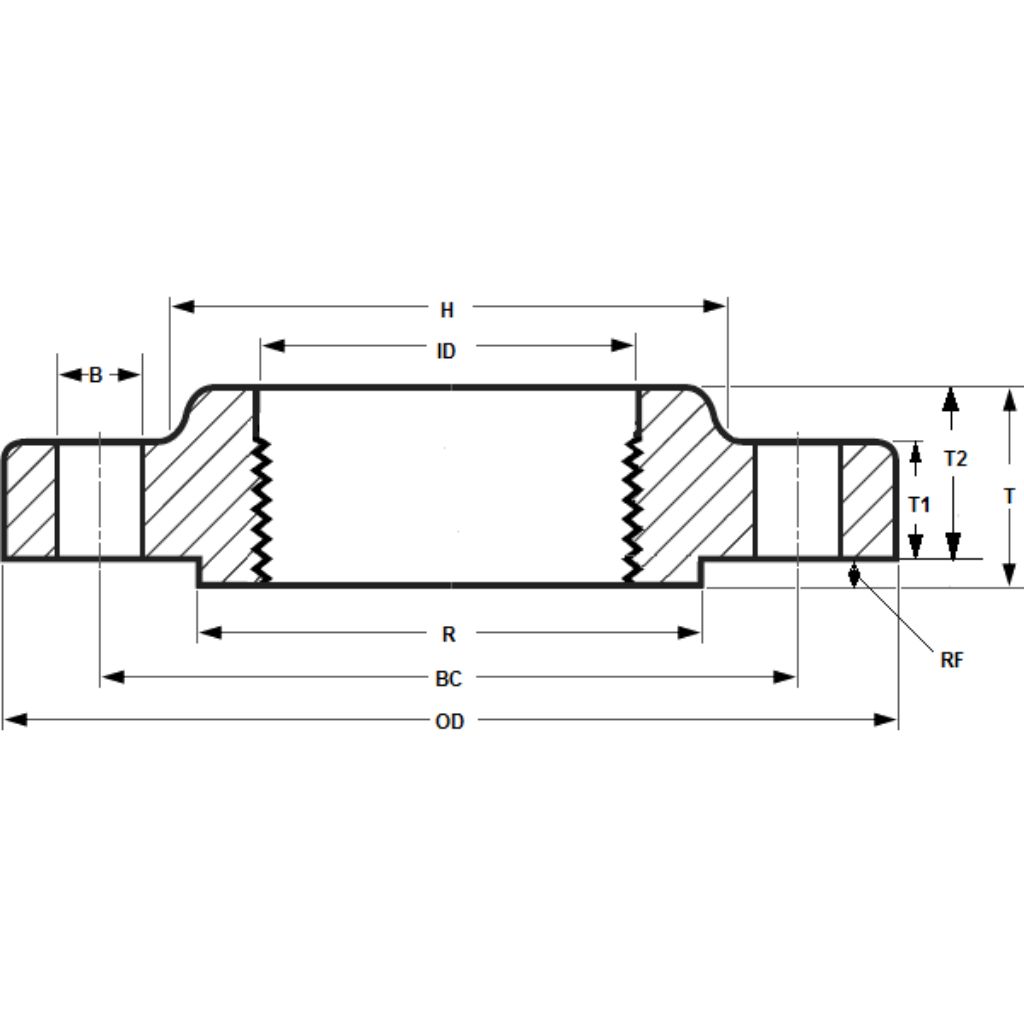

1. Threaded Flanges

Threaded flanges (Screwed flanges) are designed with threads inside the flange bore that fit on the external thread of a pipe. They are ideal for small-diameter, high-pressure applications where welding is not feasible.

Applications: Cooling water lines, fire protection systems, and air & water services.

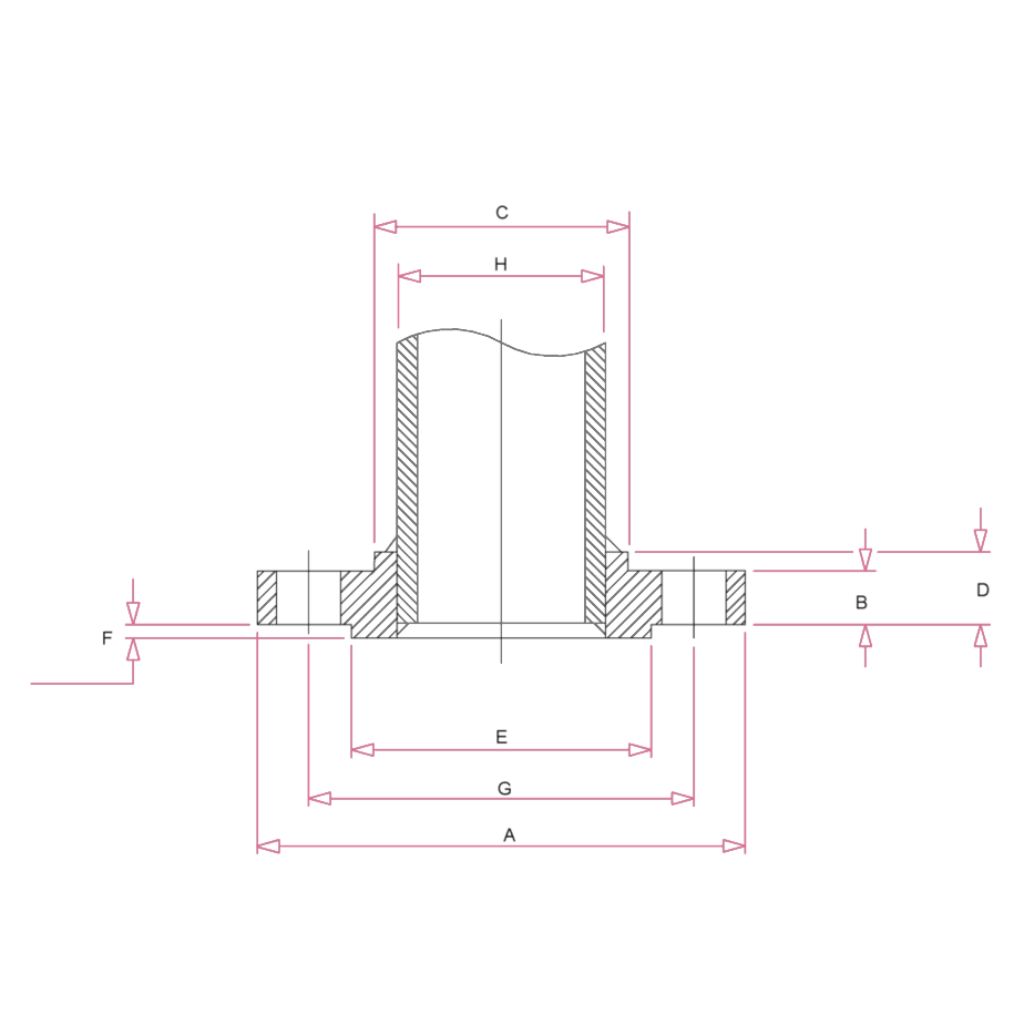

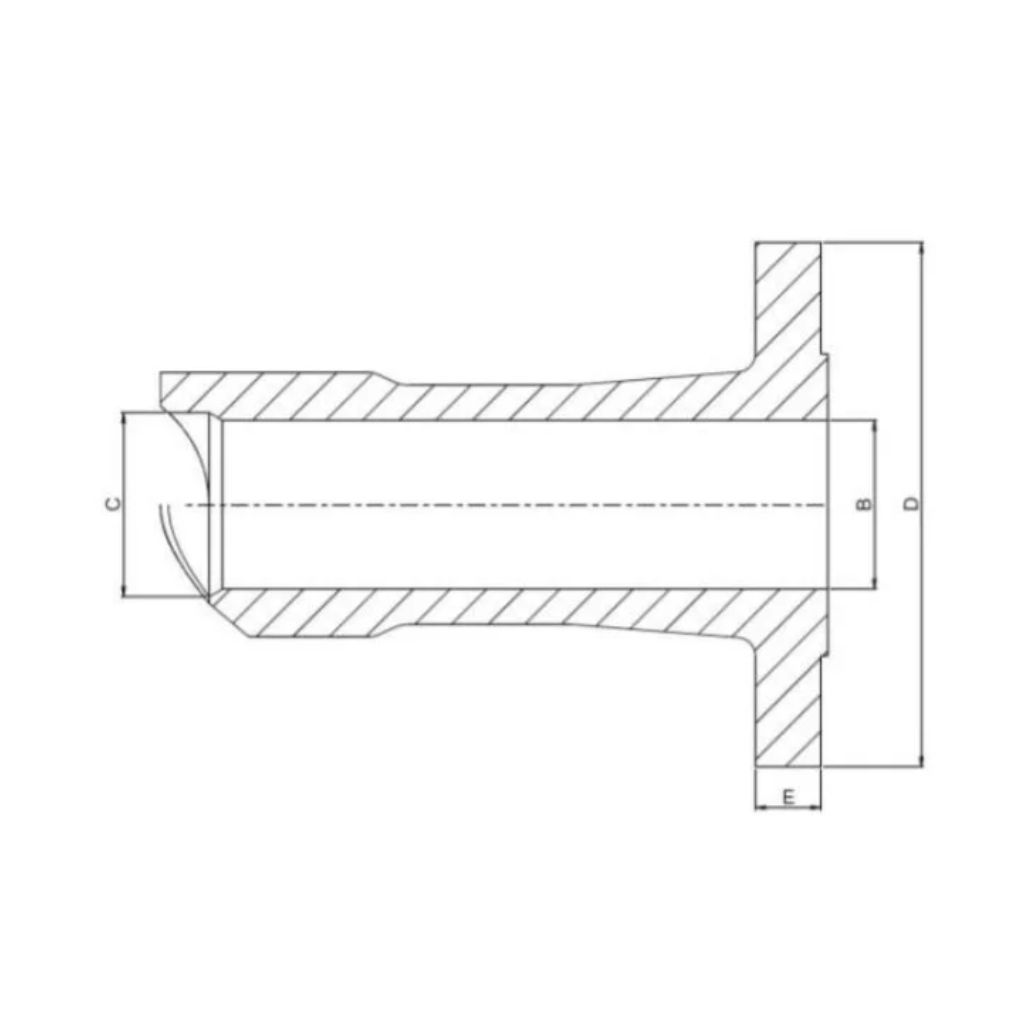

2. Socket Weld Flanges

Socket-weld flanges are used for small-diameter, high-pressure pipes. The pipe is inserted into the socket end and fillet welded, creating a smooth bore and better flow characteristics.

Applications: Hydraulic lines, chemical processing units, and compact piping systems.

3. Slip-On Flanges

Slip-on flanges are easy to install and weld onto the pipe. They have a low hub and are suitable for low-pressure applications where quick assembly is needed.

Applications: Low-pressure pipelines, water lines, and gas pipelines.

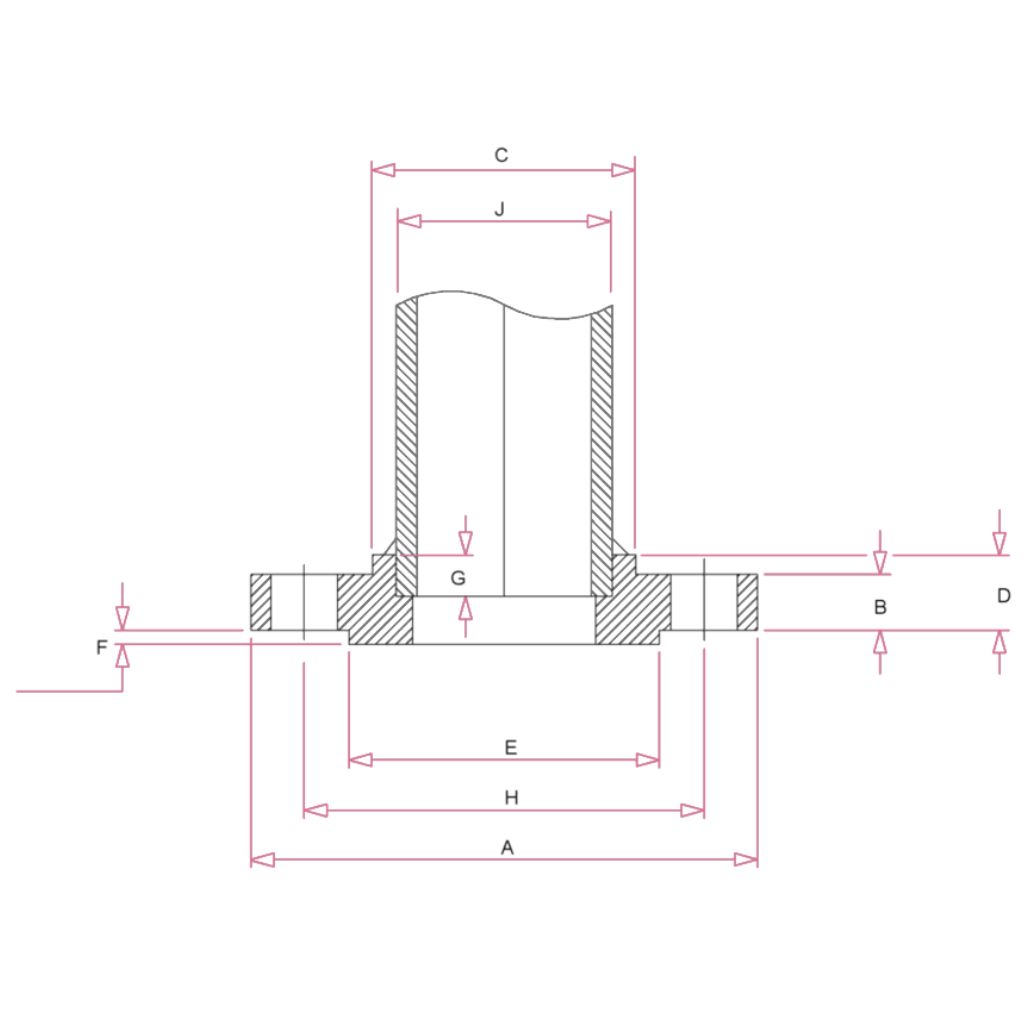

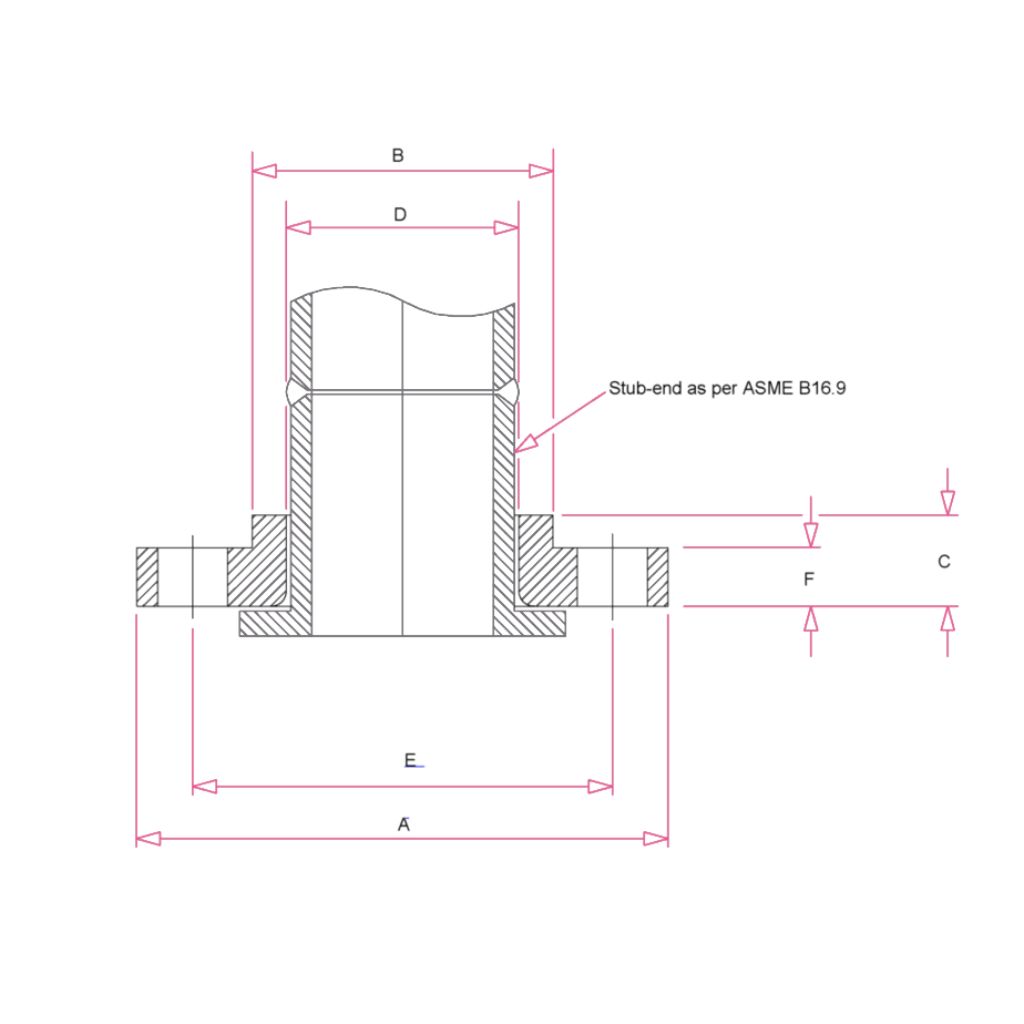

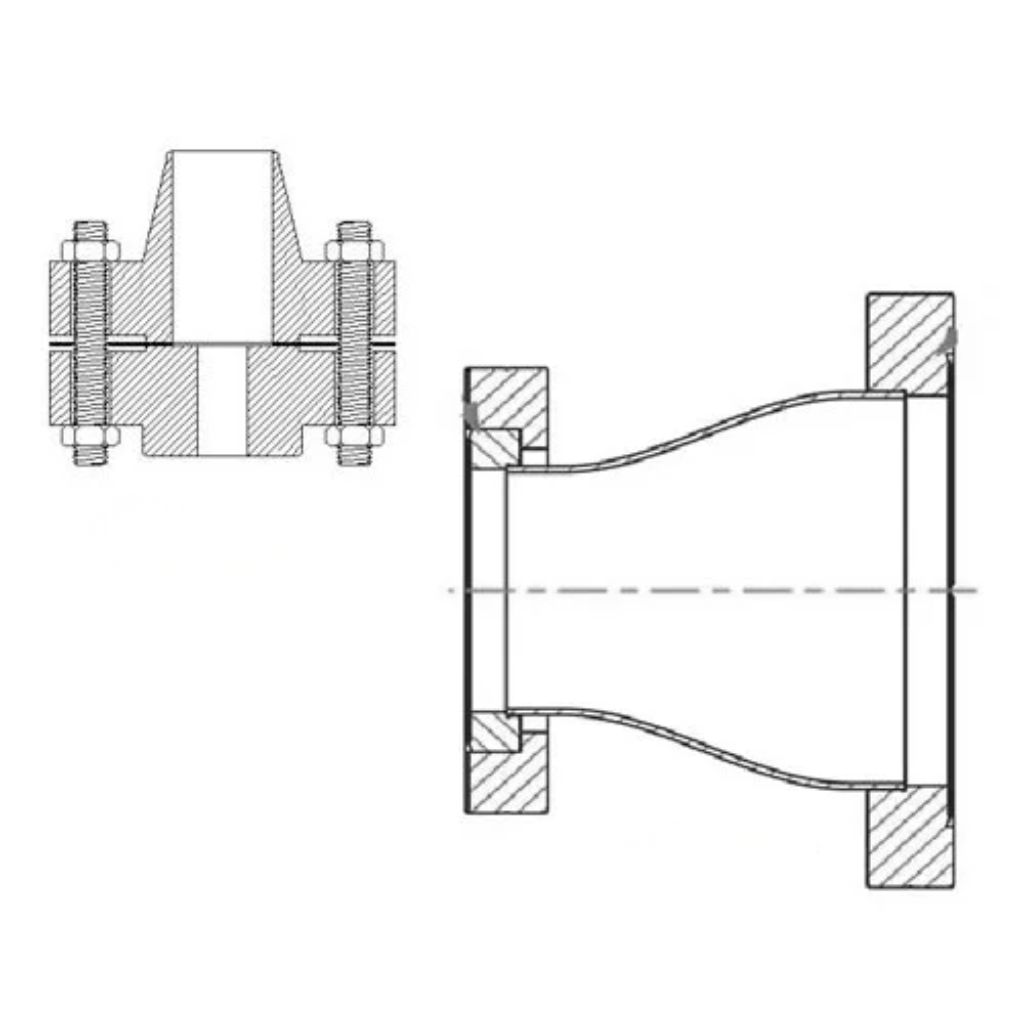

4. Lap Joint Flanges

Lap joint flanges are used with stub ends and are ideal for systems that require frequent dismantling and inspection. They allow easy alignment of bolt holes and reduce overall maintenance cost.

Applications: Food, pharmaceutical, and chemical industries.

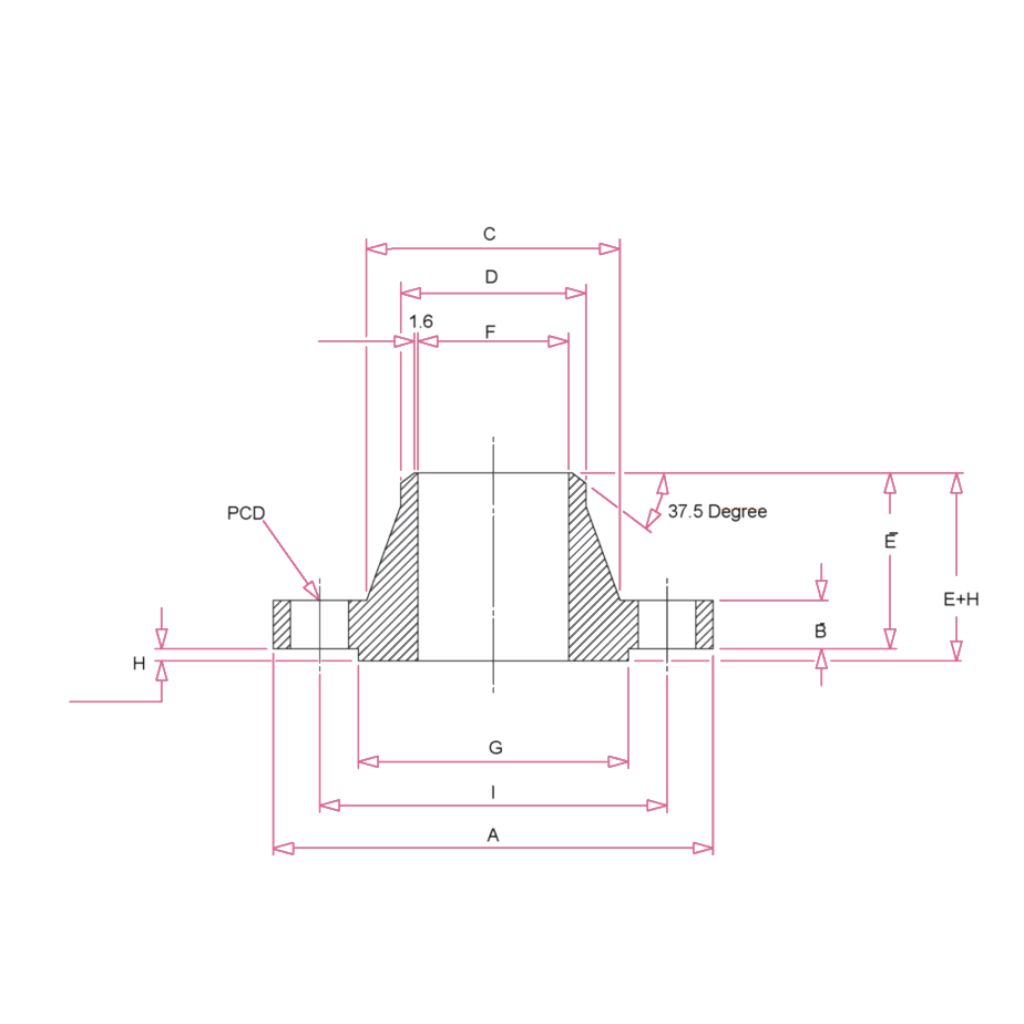

5. Weld Neck Flanges

Weld neck flanges are designed for high-pressure and high-temperature applications. They have a long tapered hub that provides reinforcement and ensures smooth stress distribution.

Applications: Refineries, thermal power plants, and chemical processing systems.

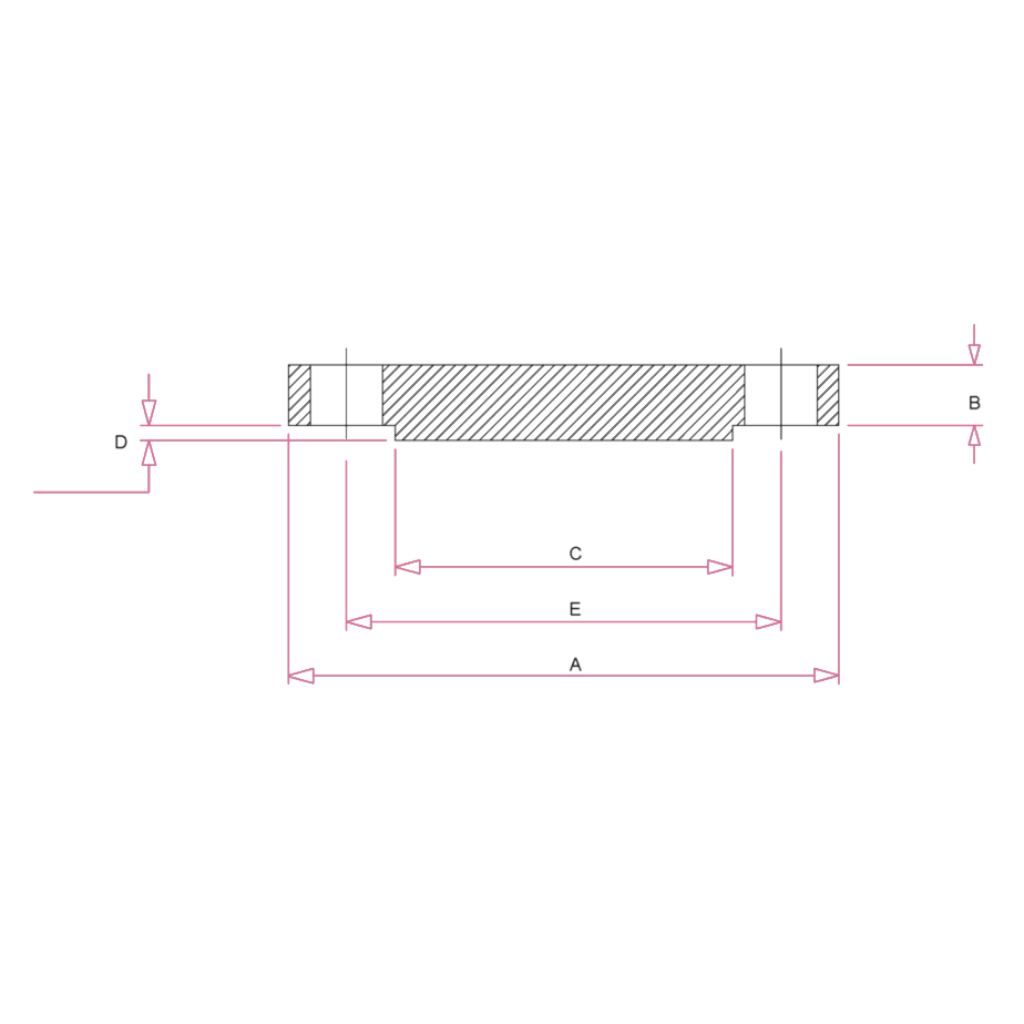

6. Blind Flanges

Blind flanges are solid discs used to close the end of a piping system or a pressure vessel opening. They can handle high-pressure conditions and allow easy access for inspection or maintenance.

Applications: Pressure vessel openings, storage tanks, and process systems.

7. Reducing Flange

Reducing flanges are used to connect pipes of different diameters. They maintain smooth fluid flow and are available in various pressure ratings and materials.

Applications: Pipeline modifications, flow control systems, and process equipment.

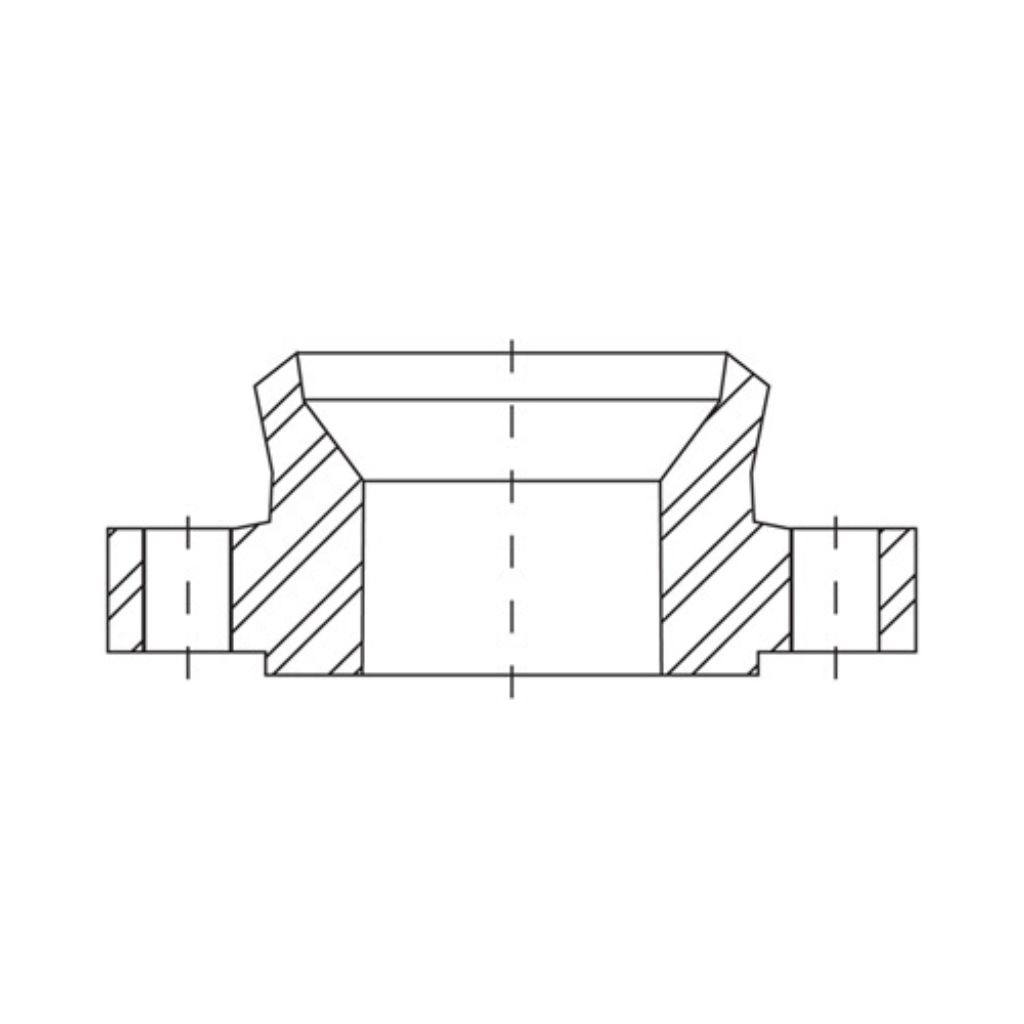

8. Expander Flange

Expander flanges are similar to weld neck flanges but have a larger bore on one end, allowing connection of a larger diameter pipe. They serve as a cost-effective alternative to using separate reducers.

Applications: Pump and compressor connections, process piping systems.

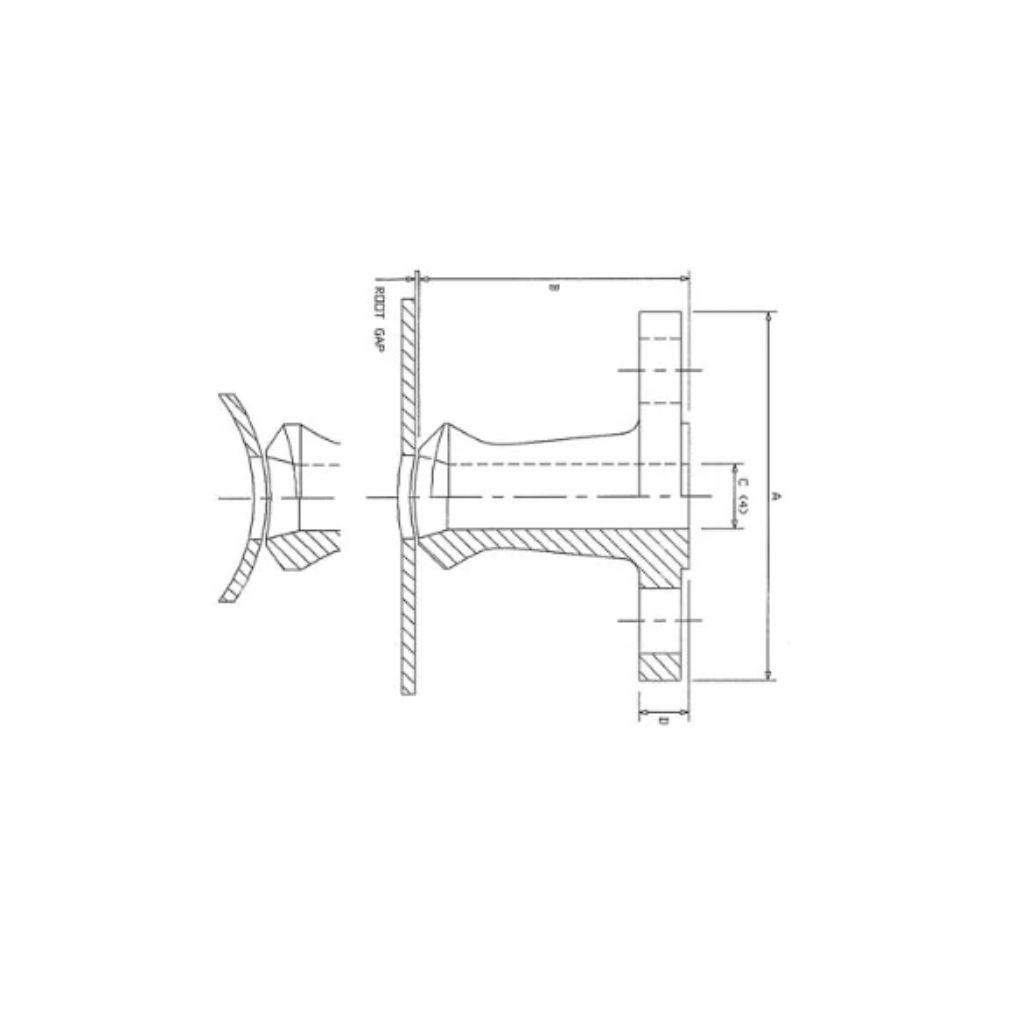

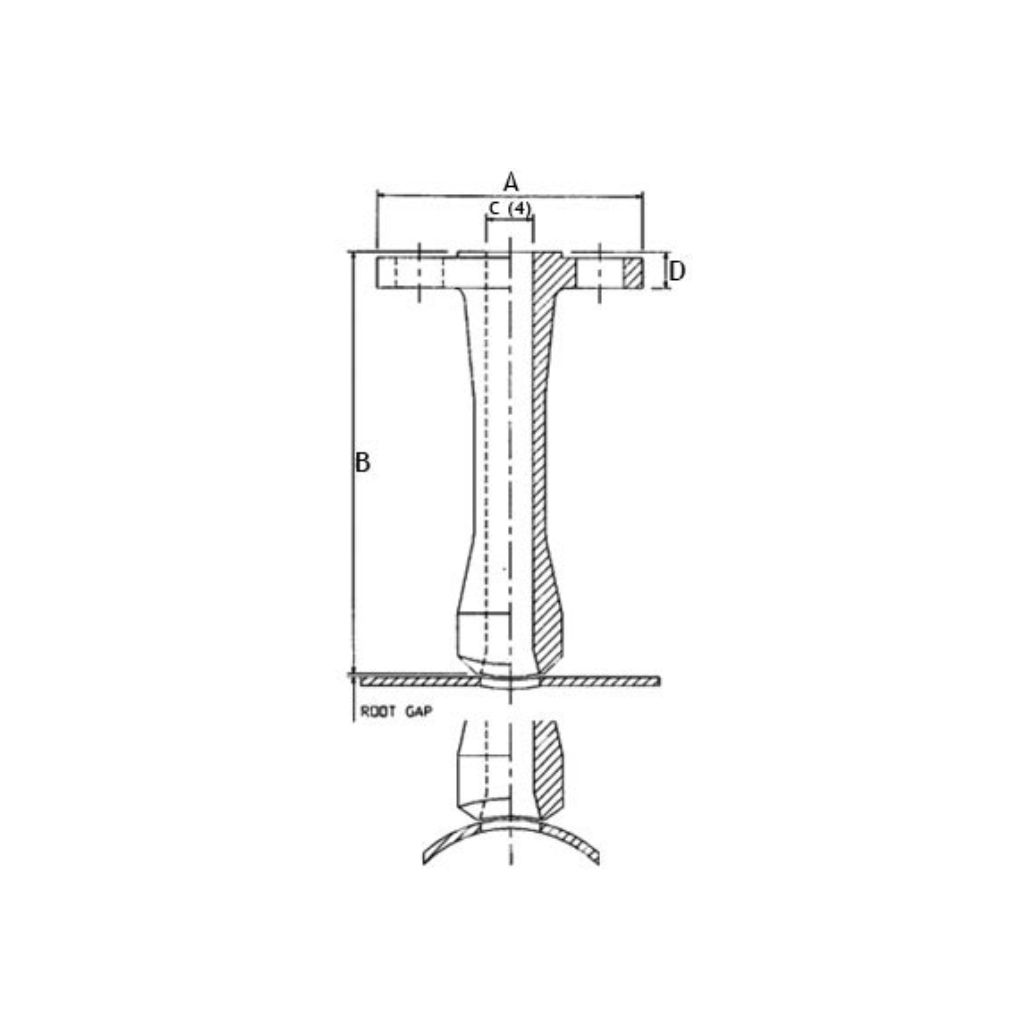

9. Flangeolet / Weldoflange / Nippoflange

These are special flanges that serve as branch connections from a main pipe. They combine the features of a weld neck flange and an olet, ensuring strong and leak-proof branch connections.

Applications: Piping manifolds, high-pressure lines, and chemical processing units.

Available Stainless Steel Flange Materials

Duplex & Super

ASTM A182 F53 / UNS S32750 (Super Duplex 2507)

ASTM A182 F55 / UNS S32760 (Zeron 100)

Ferritic Stainless Steel Grades

Martensitic Stainless

Precipitation Hardening

Special Alloys

Titanium-Stabilized Grades .

Flange Ratings / Pressure Classes

Our stainless steel flanges are available in multiple pressure ratings and classes:

ASME/ANSI B16.5 Formula

PT = (Pr x SI) / 8750

- PT = rated working pressure in psig for specified material at temperature T.

- Pr = Pressure rating as per Class in Psig.

- SI = Selected stress in Psig for specified material at Temperature T.

- Refer to ASME B16.5 Annex B for the detailed calculation of Pressure Ratings.

| Flanges pressure rating in psig for common carbon steel ASME flanges | |||||||

| ( A105 / A350 LF2 / A350 LF3 / A350 LF6) | |||||||

| Temperature (F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

Flange Sizes

Nominal Pipe Size (NPS): ½” to 48”

DN Size Range: DN15 to DN1200

Thickness: Schedule 10 to Schedule XXS (or as per client requirement)

Key Features

Corrosion and oxidation resistance

Leak-proof and durable construction

Easy installation and maintenance

Suitable for high pressure and temperature

Available in custom sizes and surface finishes

Applications

Oil & Gas Pipelines

Petrochemical Industries

Power Generation Plants

Water Treatment Systems

Marine & Offshore Applications

Food & Pharmaceutical Industries