Stainless Steel Buttweld Fitting

Stainless Steel Buttweld Fittings Supplier & Manufacturer

What are Stainless Steel Buttweld Fittings?

Stainless steel buttweld fittings are pipe fittings that are welded onto pipes to alter the flow direction, connect two sections, or change the pipe diameter. They are installed by welding, which ensures a permanent, strong, and leak-proof joint. Unlike threaded or socket weld fittings, buttweld fittings are suitable for high-pressure, high-temperature, and corrosive environments, making them ideal for demanding industries.

Manufactured as per international standards such as ASME B16.9, MSS-SP-43, and ASTM specifications, these fittings are produced in a wide range of grades, including SS 304, SS 304L, SS 316, SS 316L, SS 321, SS 347, SS 904L, Duplex, and Super Duplex stainless steels.

Types of Stainless Steel Buttweld Fittings

1. Elbows

Elbows are used to change the direction of flow in a piping system. They are classified based on angle and radius:

45° Elbow: Changes the direction of the pipe by 45 degrees.

90° Elbow: The most common type, it alters the flow direction by 90 degrees.

180° Elbow (Return Bend): Used to reverse the flow completely.

Short Radius (SR) Elbow: Compact design, suitable where space is limited.

Long Radius (LR) Elbow: Provides smoother flow with less pressure drop.

2. Reducers

Reducers are used to connect pipes of different diameters:

Concentric Reducer: Has a common centerline and is typically used in vertical piping systems.

Eccentric Reducer: One side is flat, preventing air accumulation; ideal for horizontal pipelines.

3. Tees

Tees allow the flow to branch off into two directions. Types include:

Equal Tee: All three outlets are of the same diameter.

Reducing Tee: The branch outlet has a smaller diameter than the main run pipe.

4. Crosses

A cross fitting connects four pipes at a single point. It is less commonly used but crucial in some complex piping systems.

5. Caps & End Caps

Caps are used to terminate the end of a pipe, protecting it from contaminants and sealing the line when required.

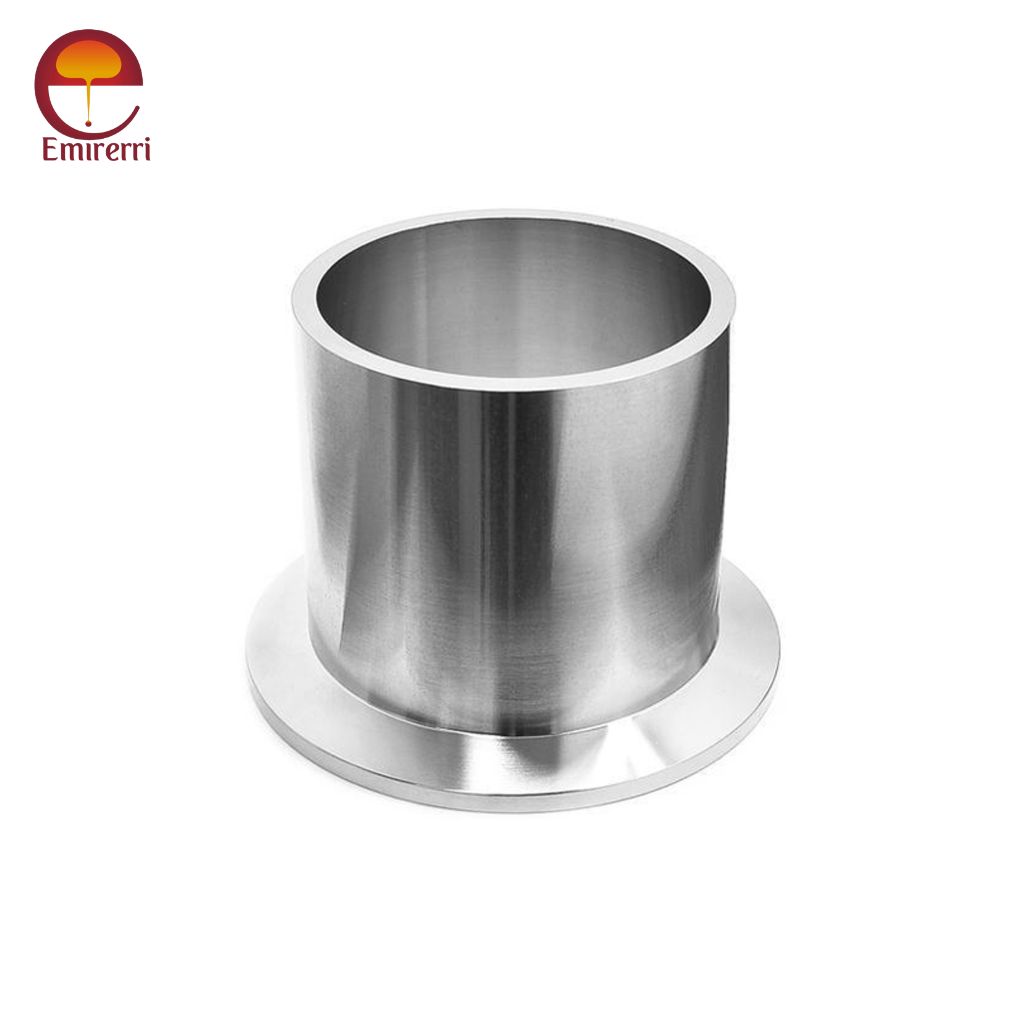

6. Stub Ends

Stub ends are used with lap joint flanges to facilitate easy dismantling of piping systems, especially in cases requiring frequent inspection or maintenance.

7. Bends

Unlike elbows, bends have a larger radius, providing smoother flow with minimal pressure loss.

8. Collars

Collars are fittings that connect two pipes, often used with other fittings to maintain structural integrity.

9. Laterals

A lateral fitting is similar to a tee but allows branch connection at an angle (commonly 45°).

Advantages

Corrosion Resistance: Stainless steel provides excellent resistance to corrosion, oxidation, and chemical attack.

Durability: Welded connections offer superior strength and longevity compared to mechanical joints.

Leak-Proof Design: Buttweld joints are welded into the pipeline, eliminating leakage risks.

Hygienic & Easy to Clean: Especially useful in food, beverage, and pharmaceutical industries.

Cost-Effective in Long Term: Although initial costs may be higher than threaded fittings, the durability and low maintenance make them economical over time.

Variety of Sizes & Grades: Available in a wide range of diameters, wall thicknesses, and stainless steel grades.

Stainless Steel Pipe Fitting Grade

ASTM A815 – Ferritic / Austenitic (Duplex & Super Duplex) Grades

ASTM A815 WPS32950 (Duplex)

ASTM A815 WPS32101 (Lean Duplex)

ASTM A815 WPS32202 (Lean Duplex)

ASTM A815 WPS32550 (Super Duplex)

ASTM A815 WPS39274 (Super Duplex)

Applications

Due to their superior properties, stainless steel buttweld fittings are used in diverse industries:

1. Oil & Gas Industry

Used in offshore and onshore pipelines.

Handles corrosive fluids, high-pressure steam, and hydrocarbons.

Provides reliability in critical refinery operations.

2. Petrochemical & Chemical Processing

Ideal for transporting acids, alkalis, and solvents.

Resists chemical corrosion and withstands extreme process conditions.

Extensively used in fertilizer plants, chemical reactors, and polymer production.

3. Power Generation

Thermal power plants use buttweld fittings for high-temperature steam pipelines.

Nuclear plants utilize them in cooling and reactor piping systems.

Renewable energy projects like geothermal plants rely on stainless steel fittings for high-pressure fluid circulation.

4. Food & Beverage Industry

Stainless steel fittings ensure hygiene and prevent contamination.

Used in breweries, dairy plants, sugar mills, and soft drink manufacturing units.

Grades like SS 316 and SS 304 are particularly popular.

5. Pharmaceuticals & Biotechnology

Ensures sterile, contamination-free transfer of fluids and chemicals.

Buttweld fittings in SS 316L are widely used due to low carbon content and enhanced corrosion resistance.

6. Water Treatment & Desalination Plants

Suitable for handling saline water and corrosive chemicals used in water treatment.

Prevents scaling, pitting, and rust formation in pipelines.

7. Marine & Shipbuilding

Resistant to seawater corrosion.

Extensively used in ballast systems, fuel pipelines, and cooling systems of ships.

8. Construction & Infrastructure

Stainless steel buttweld fittings are used in fire-fighting systems, HVAC systems, and high-rise plumbing.

Offer durability and aesthetic appeal for exposed piping.

9. Automotive & Aerospace

Utilized in exhaust systems, fuel lines, and hydraulic applications.

Lightweight, durable, and corrosion-resistant characteristics make them indispensable in modern designs.

10. Mining & Slurry Transport

Handles abrasive slurries, chemicals, and high-pressure transport lines.

Reduces downtime caused by corrosion and wear.