Carbon Steel Flanges

Carbon Steel Flanges

Manufacturer, Supplier & Exporter

Emirerri Steel is a leading manufacturer, supplier, and exporter of Carbon Steel Flanges, offering superior strength, durability, and corrosion resistance. Our flanges are manufactured in accordance with ASTM, ASME, ANSI, DIN, and EN standards to meet diverse industrial requirements.

We provide an extensive range of carbon steel flanges in various types, pressure classes, materials, and sizes, engineered to ensure reliable pipeline connectivity and long-lasting performance.

Types of Carbon Steel Flanges

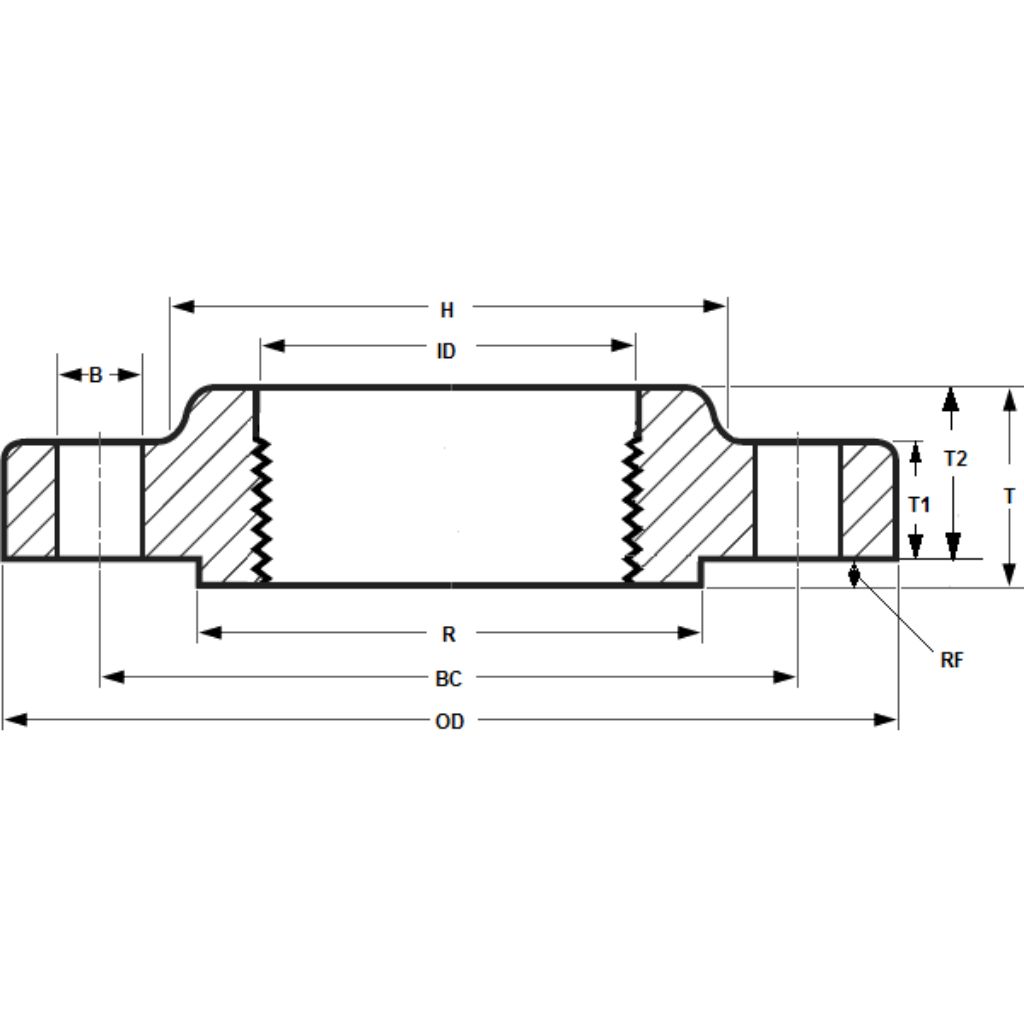

1. Threaded Flange

2. Socket Weld Flange

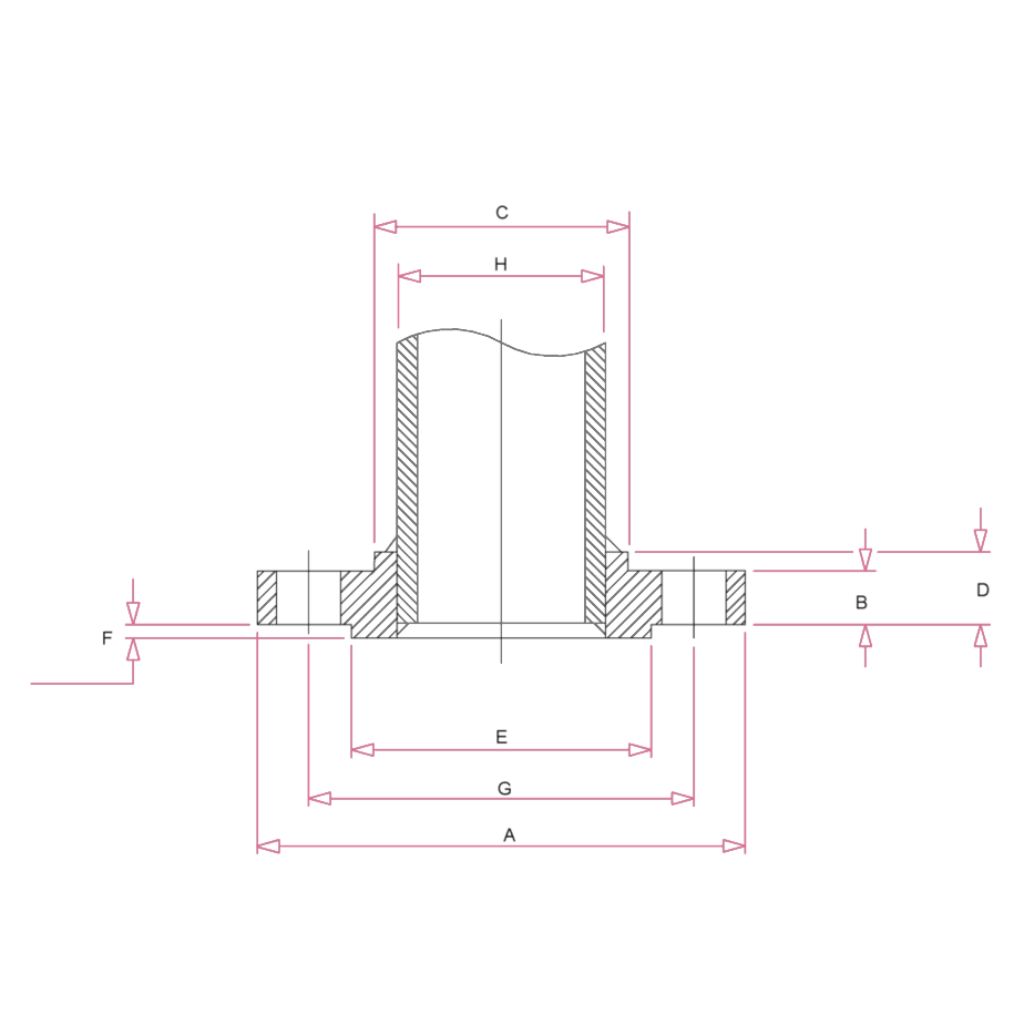

3. Slip-On Flanges

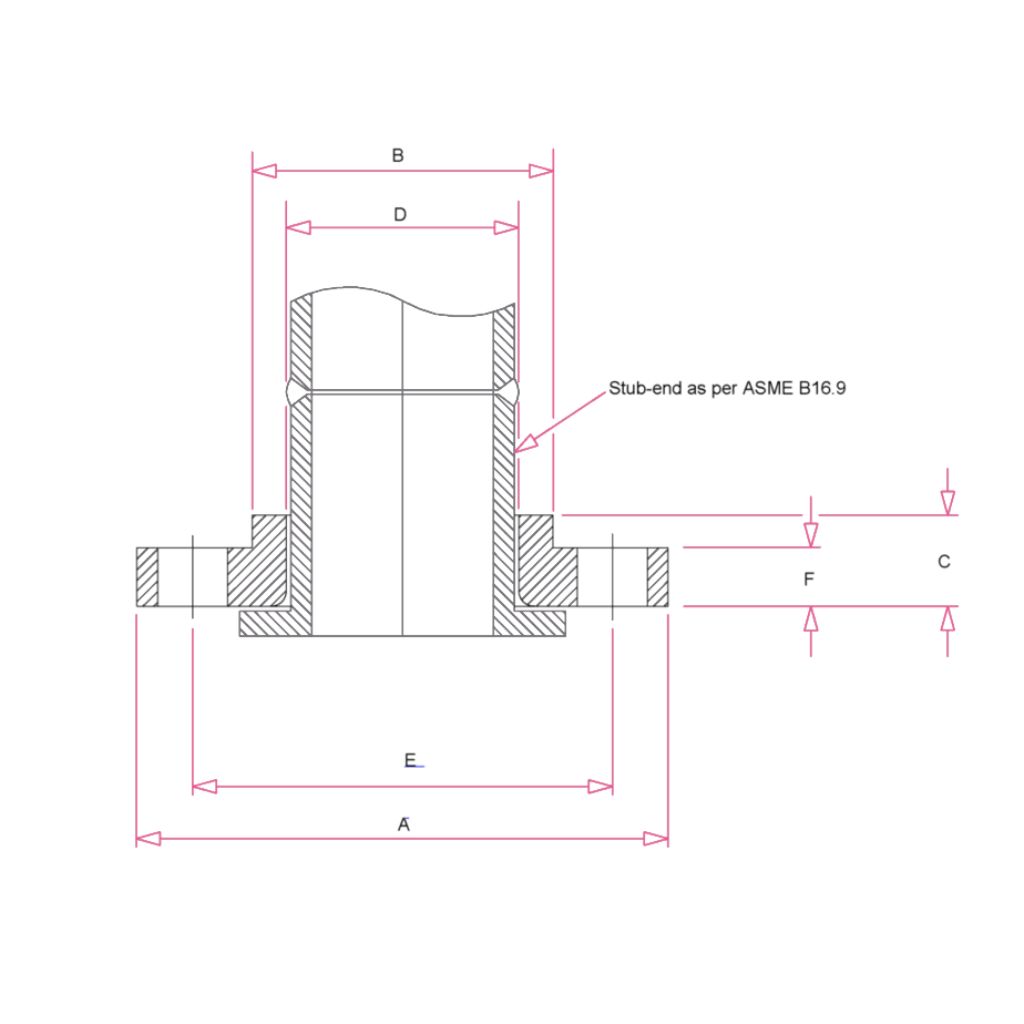

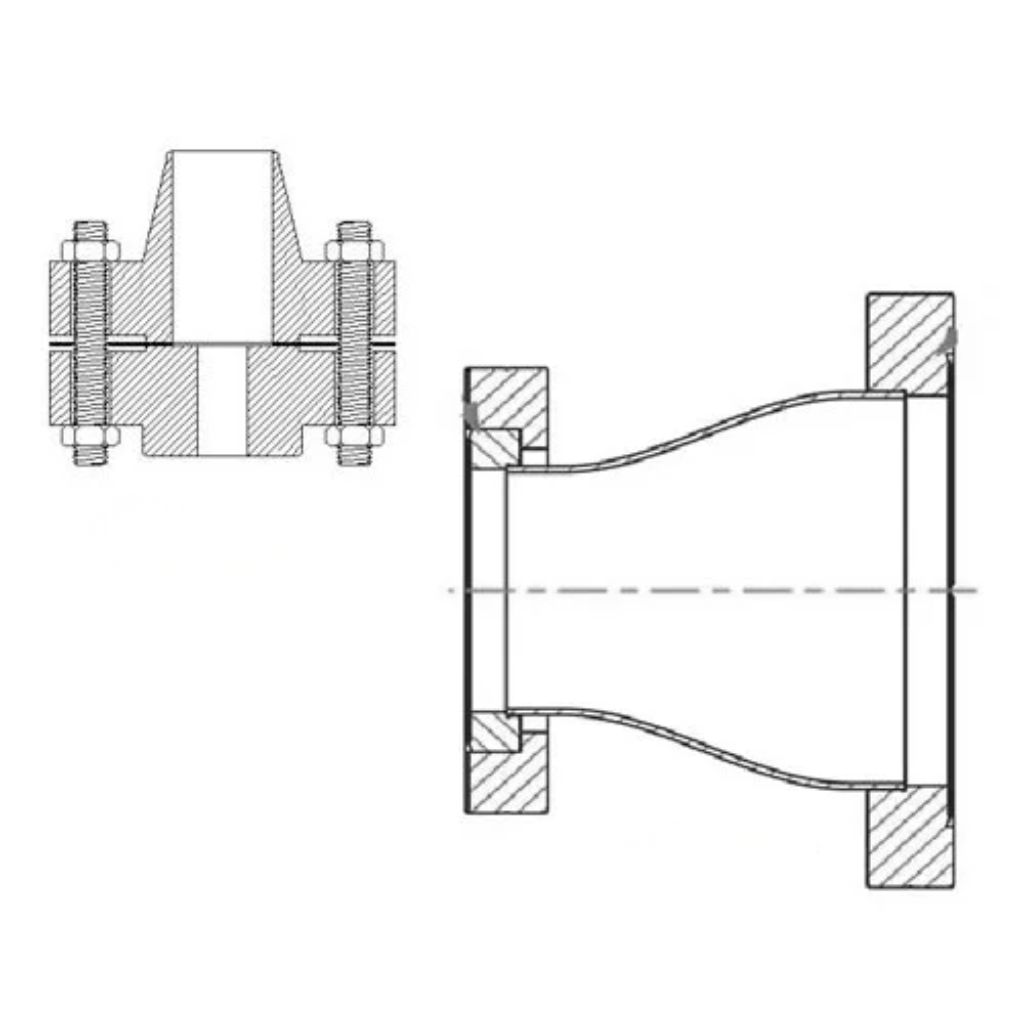

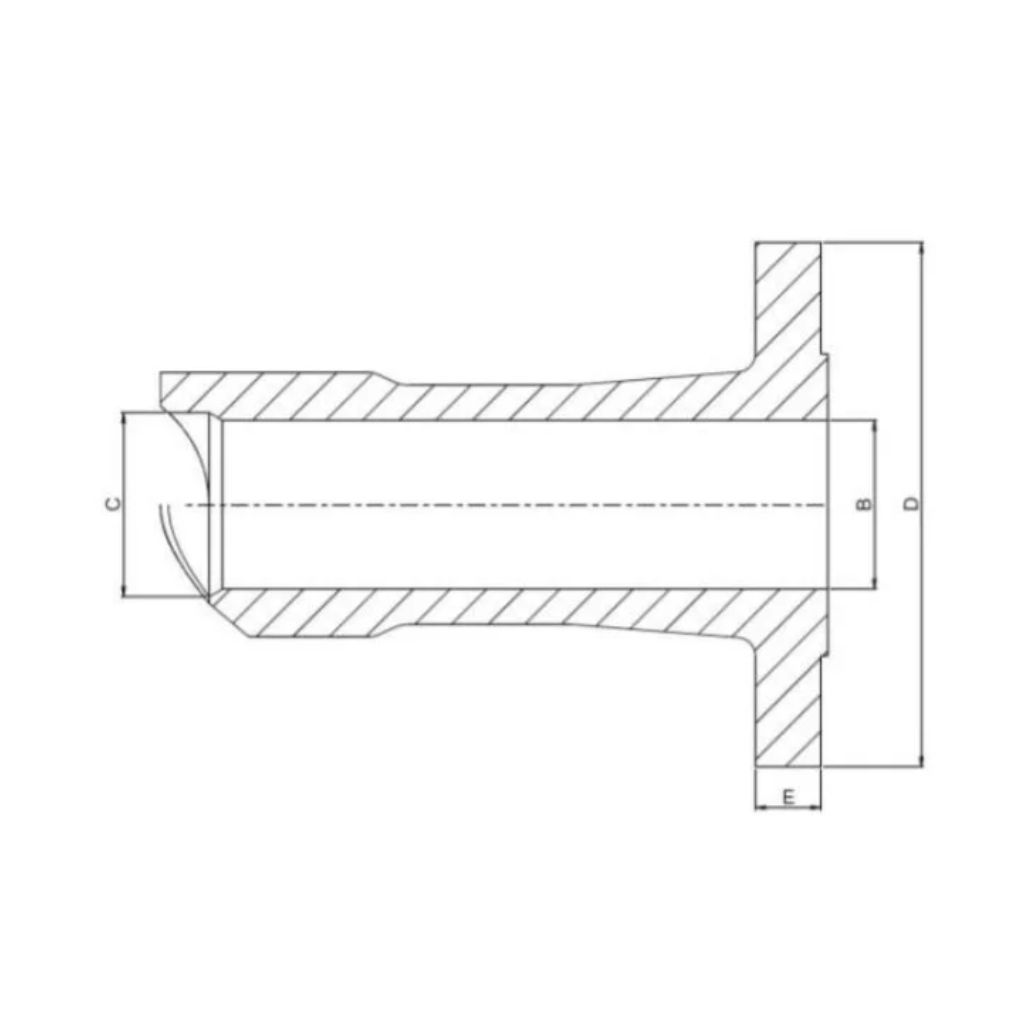

4. Lap Joint Flanges

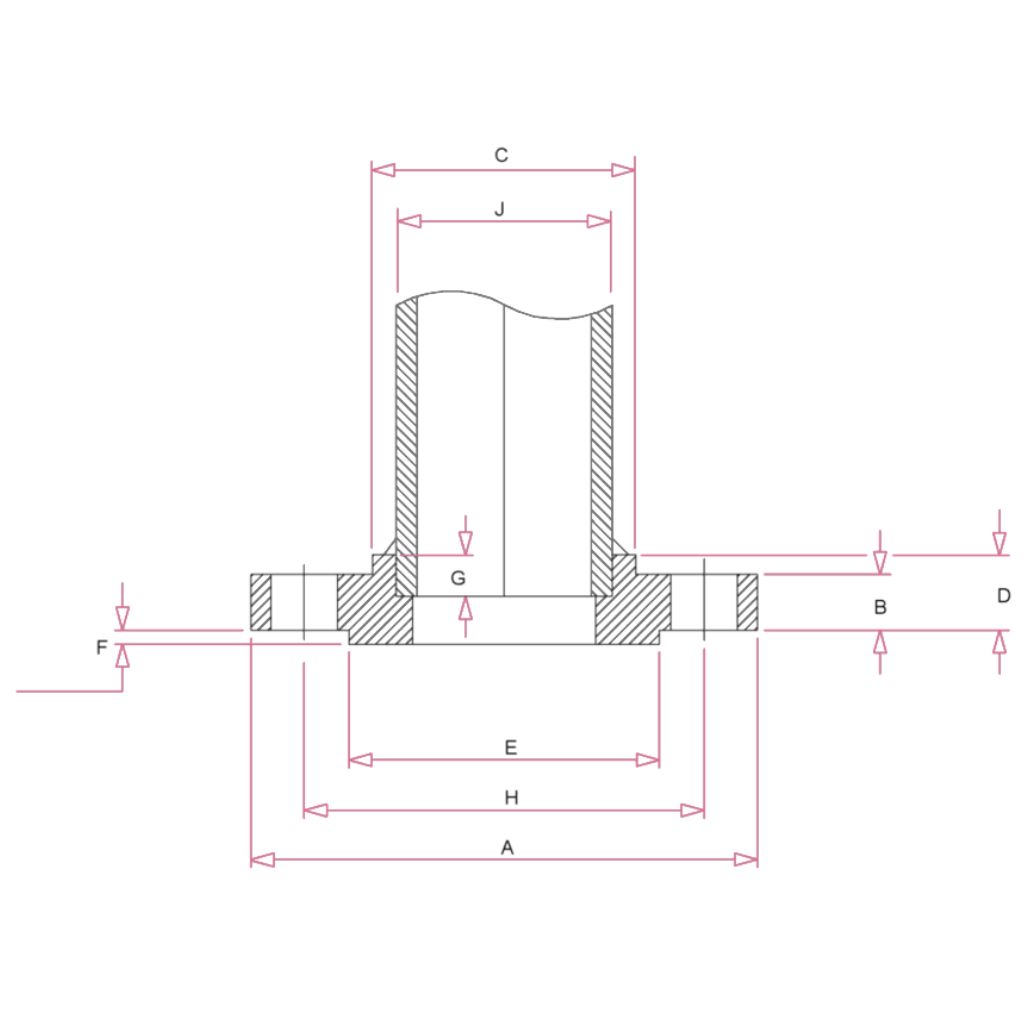

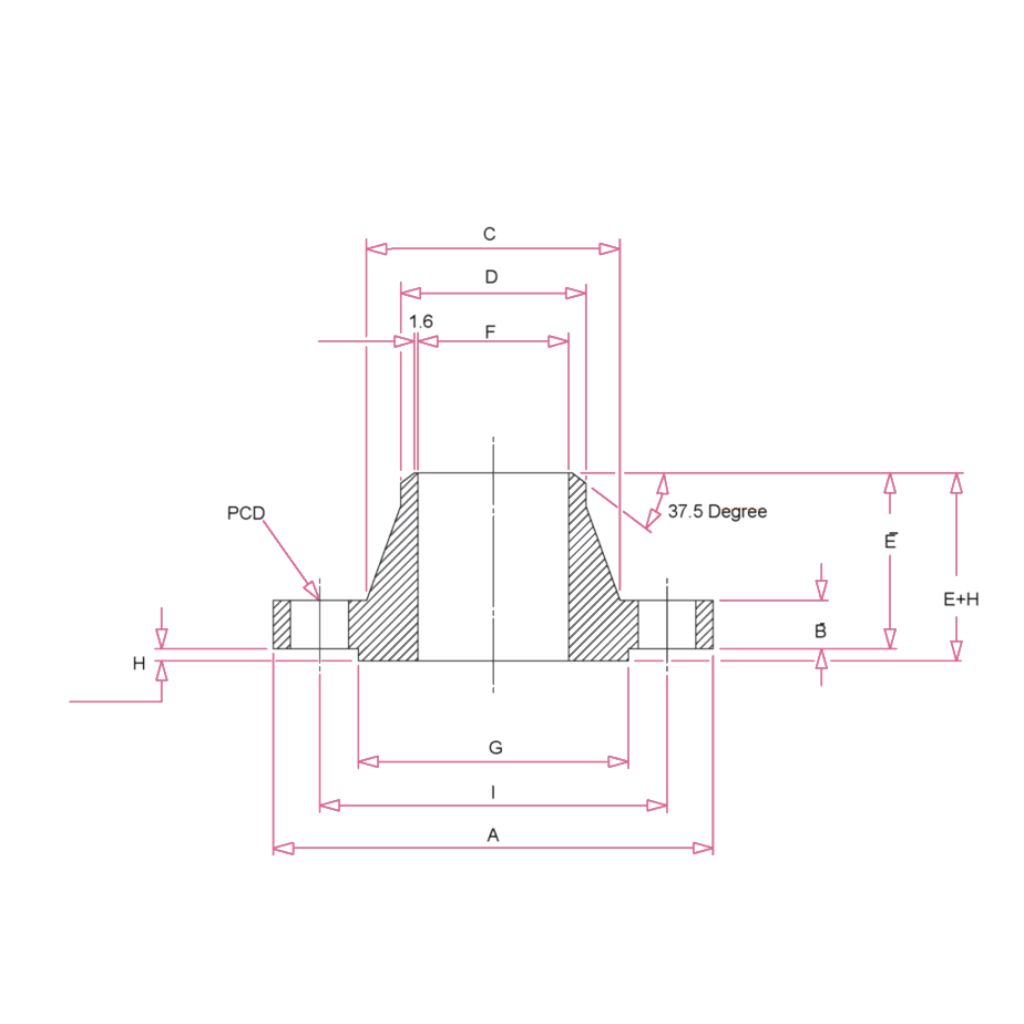

5. Weld Neck Flanges

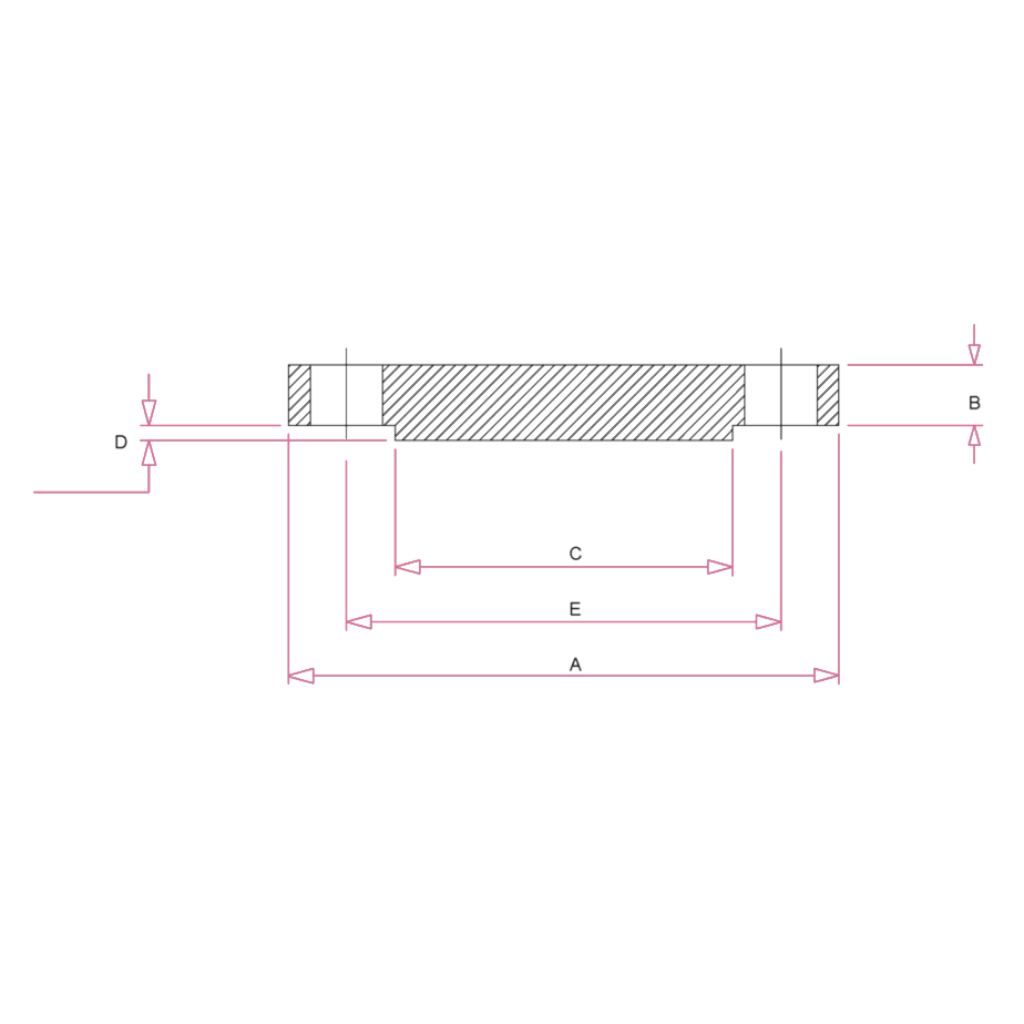

6. Blind Flanges

7. Reducing Flange

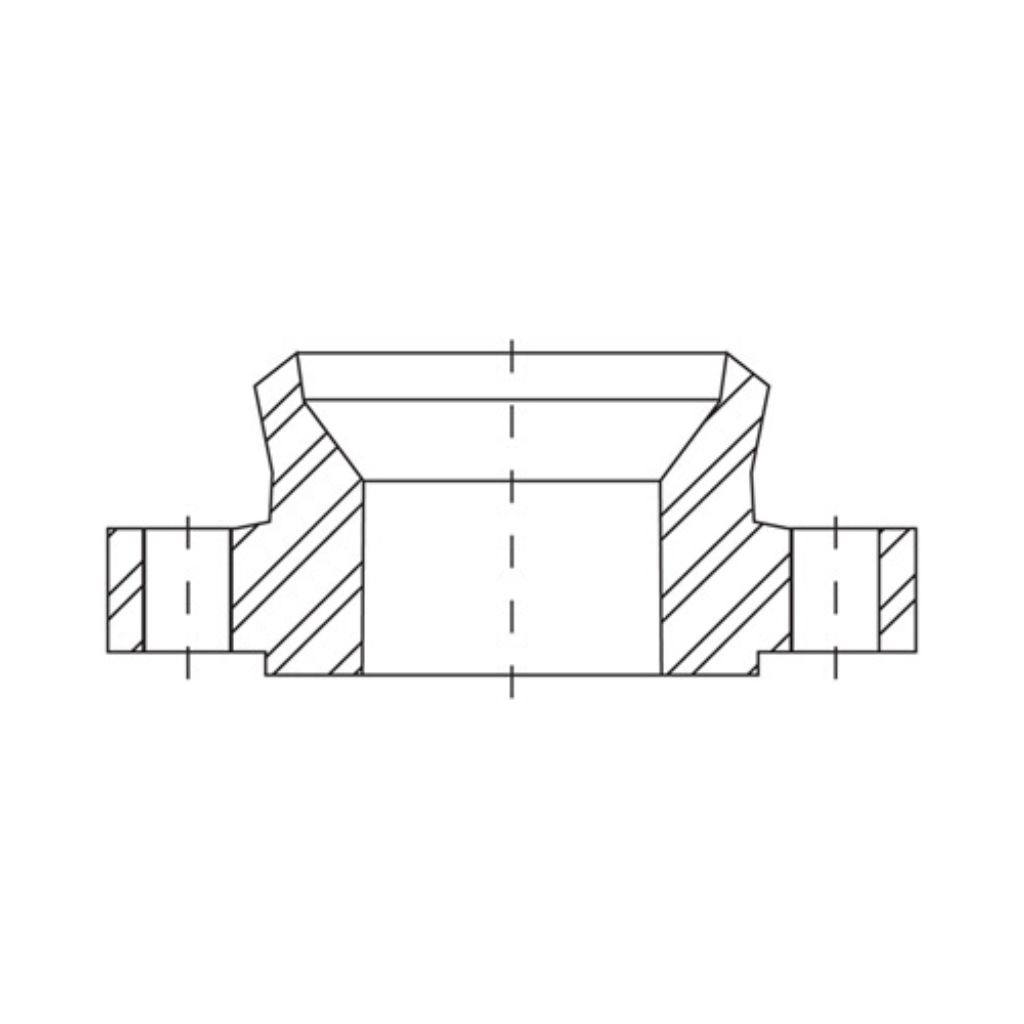

8. Expander Flange

9. Flangeolet

Available Stainless Steel Flange Materials

Low-temperature carbon steel flanges for cryogenic applications

High-yield strength carbon steel flanges for oil & gas industries.

General-purpose carbon steel forged flanges for moderate pressure applications.

Carbon Steel Forged Flanges for ambient and high-temperature service.

Flange Ratings / Pressure Classes

Our stainless steel flanges are available in multiple pressure ratings and classes:

ASME/ANSI B16.5 Formula

PT = (Pr x SI) / 8750

- PT = rated working pressure in psig for specified material at temperature T.

- Pr = Pressure rating as per Class in Psig.

- SI = Selected stress in Psig for specified material at Temperature T.

- Refer to ASME B16.5 Annex B for the detailed calculation of Pressure Ratings.

| Flanges pressure rating in psig for common carbon steel ASME flanges | |||||||

| ( A105 / A350 LF2 / A350 LF3 / A350 LF6) | |||||||

| Temperature (F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

Flange Sizes

Nominal Pipe Size (NPS): ½” to 48”

DN Size Range: DN15 to DN1200

Thickness: Schedule 10 to Schedule XXS (or as per client requirement)

Key Features

High mechanical strength and durability

Corrosion and wear resistance

Easy to install and maintain

Suitable for high-pressure & temperature environments

Available in customized sizes and finishes

Applications

Oil & Gas Transmission Lines

Petrochemical and Refinery Systems

Power Generation Plants

Water Supply & Treatment Facilities

Marine and Offshore Applications

Chemical Processing Units